I need to create a definitive guide on safety boots, but it's not just about listing features. It's about empowering the user to make an informed decision that prioritizes safety while ensuring comfort and usability.

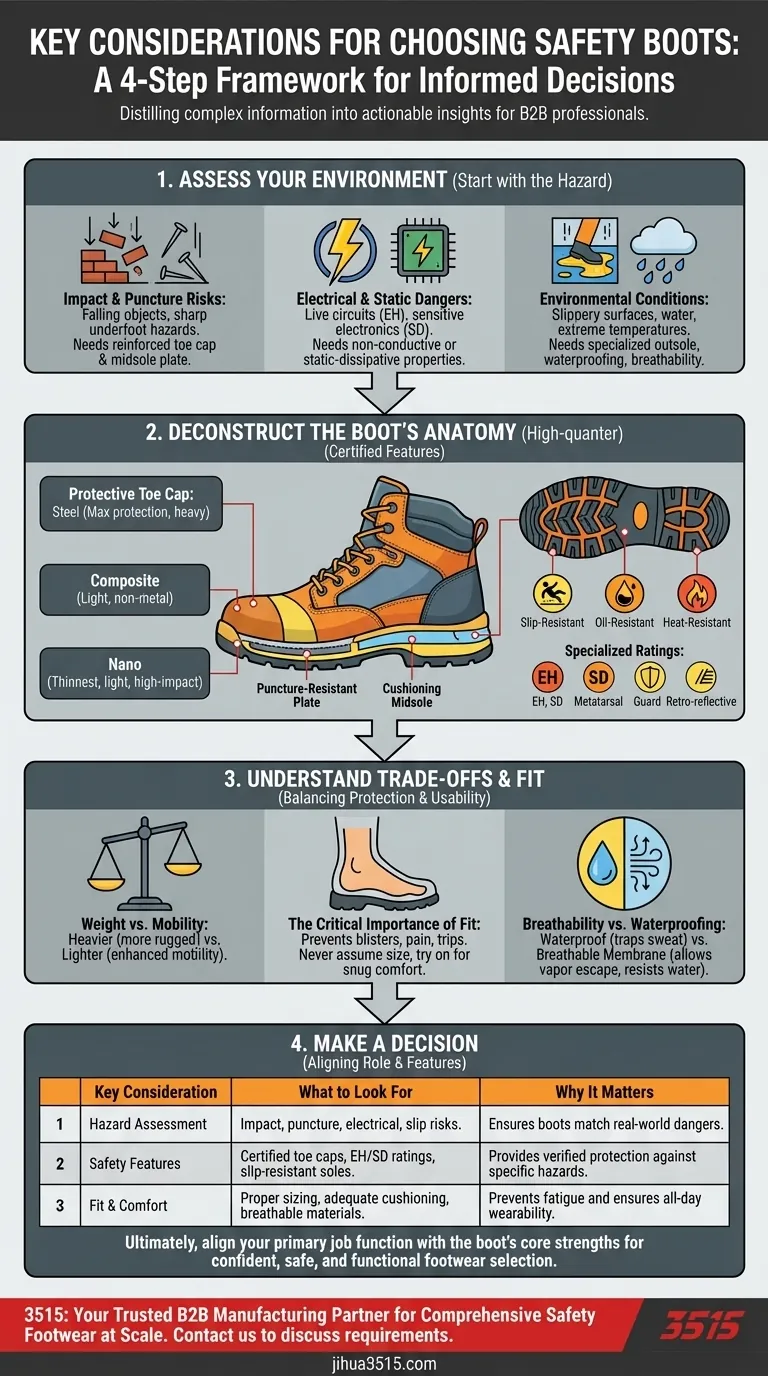

My initial thought is to structure this around two needs: the immediate "what" of choosing boots, and the deeper "why" – understanding the specific hazards of their work environment. I see this as a four-part framework:

- Assess Your Environment: Start by identifying the specific hazards present in the work environment.

- Deconstruct the Boot's Anatomy: Understand the purpose of different safety features.

- Understand the Trade-offs: Acknowledge that choosing the "perfect" boot involves balancing protection with comfort.

- Make a Decision: Apply your knowledge to find the best boots for your needs.

I've reviewed the references, and a clear picture is forming: impact and puncture resistance are crucial; electrical hazards require specific ratings; environmental conditions (water, oil, temperature) demand specialized features. Comfort and fit, as it turns out, are just as important as the protective elements.

To make the guide truly useful, I will include a detailed analysis of the trade-offs, like weight vs. protection, and the critical importance of a proper fit. A clear section on specific hazards, such as falling objects, electrical risks, and slippery surfaces, will be provided.

The final guide will present the key considerations upfront (hazard assessment, safety feature selection, and a proper fit) and provide a deep dive into each topic to give professionals a comprehensive framework for selecting safety boots. When choosing safety boots, the key considerations are to first assess the specific hazards of your work environment, such as impact, puncture, or electrical risks. Next, select boots with certified safety features like the correct type of protective toe and slip-resistant sole that directly counter those hazards. Finally, you must ensure a proper and comfortable fit, as this is critical for both daily wearability and preventing injury.

The most effective safety boot is not the one with the most features, but the one precisely aligned with your specific job hazards. True safety is a combination of certified protection, environmental suitability, and a correct fit that ensures comfort and prevents fatigue.

Start with the Hazard, Not the Boot

The most common mistake is choosing a boot based on a single feature or brand. A truly effective choice begins with a clear-eyed assessment of your work environment. You must match the boot's protective capabilities to the real-world risks you face daily.

Identify Impact and Puncture Risks

The primary function of most safety boots is to protect against falling objects and sharp underfoot hazards.

Impact protection comes from the reinforced toe cap, designed to resist crushing forces from heavy machinery or dropped materials. Puncture protection is provided by a plate in the midsole that stops nails or other sharp objects from penetrating the sole.

Assess Electrical and Static Dangers

Many job sites have invisible electrical hazards that require specialized footwear.

Electrical Hazard (EH) rated boots have soles and heels that are non-conductive, protecting you from accidental contact with live electrical circuits. Conversely, Static Dissipative (SD) footwear is designed to reduce the buildup of static electricity, which is critical in environments where a static spark could damage sensitive electronics or ignite flammable materials.

Evaluate Environmental Conditions

The surfaces you walk on and the climate you work in are just as important as the acute hazards.

A boot's outsole is your primary defense against slips and falls. Look for designations indicating resistance to oil, water, and abrasion. For outdoor or wet conditions, waterproofing is essential, while breathability is key for preventing discomfort in hot environments.

Deconstructing Key Safety Features

Once you understand your environment, you can decode the features of the boot itself. Industry standards, like those from ASTM International (e.g., ASTM F2413), certify that these components meet specific performance criteria.

The Protective Toe Cap: Steel, Composite, or Nano?

The safety toe is the boot's most iconic feature, but the material makes a significant difference.

- Steel Toes are the traditional standard, offering maximum protection against impact and compression. They are often the most affordable option but are also the heaviest and will conduct temperature.

- Composite Toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter than steel, do not conduct electricity or temperature, and won't set off metal detectors.

- Nano Toes are the most modern option, using carbon nanotubes to create the thinnest and lightest type of safety toe, offering high-impact resistance with minimal bulk.

Underfoot Protection: Midsoles and Outsoles

The bottom of the boot provides support, traction, and protection from ground-level threats.

The midsole provides cushioning and, in many safety boots, houses a puncture-resistant plate. The outsole is the layer that contacts the ground, designed with specific tread patterns and compounds for slip resistance and durability.

Specialized Ratings for Specific Risks

Beyond the toe cap, look for other ratings that match your hazard assessment.

A boot marked EH is critical for electricians, while one marked SD is necessary for those working with sensitive electronics. Other features to look for include metatarsal guards for top-of-foot protection or retro-reflective trim for visibility in low-light conditions.

Understanding the Trade-offs: Protection vs. Usability

There is no single "best" safety boot, only the best boot for a specific application. Every design choice involves a trade-off between maximum protection and all-day wearability.

Weight and Mobility

Heavier, more rugged boots often provide superior protection but can lead to fatigue over a long shift. Lighter boots with composite toes enhance mobility and reduce strain but may offer less robust overall protection than their heavy-duty counterparts.

The Critical Importance of Fit

An improperly fitting boot is a safety hazard. It can cause blisters, chronic pain, and even lead to a trip or fall by altering your balance. Because they cannot be tightened, pull-on boots require an especially precise fit. Never assume your size; always try on boots to ensure a snug but comfortable feel.

Breathability vs. Waterproofing

A fully waterproof boot is excellent at keeping water out but can also trap sweat inside, leading to discomfort. A boot with a breathable membrane offers a compromise, allowing moisture vapor to escape while still resisting external water.

Making the Right Choice for Your Role

To simplify your decision, align your primary job function with the boot's core strengths.

- If your primary focus is heavy industry or construction: Prioritize a steel toe and a puncture-resistant sole for maximum impact protection.

- If your primary focus is electrical or utility work: Insist on an EH-rated boot with a non-metallic composite toe.

- If your primary focus is warehouse work or logistics: Choose a lightweight composite or nano toe boot with excellent cushioning and certified slip resistance.

- If your primary focus is working in wet or outdoor environments: Select a boot with a waterproof membrane and an aggressive, oil-and-slip-resistant outsole.

By methodically matching the boot’s features to your specific hazards, you can confidently select footwear that provides both safety and functional comfort.

Summary Table:

| Key Consideration | What to Look For | Why It Matters |

|---|---|---|

| Hazard Assessment | Identify impact, puncture, electrical, or slip risks. | Ensures boots match real-world dangers. |

| Safety Features | Certified toe caps (steel/composite), EH/SD ratings, slip-resistant soles. | Provides verified protection against specific hazards. |

| Fit & Comfort | Proper sizing, adequate cushioning, and breathable materials. | Prevents fatigue and ensures all-day wearability. |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work shoes, engineered to meet rigorous standards for impact, puncture, and electrical hazards. Whether you need lightweight composite toes for logistics or heavy-duty steel toes for construction, we deliver reliable protection and comfort at scale.

Ready to equip your team with high-quality safety boots tailored to your specific needs? Contact us today to discuss your requirements and discover how 3515 can be your trusted manufacturing partner.

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- Does OSHA require specific industries to wear steel toe boots? The Truth About Safety Footwear Compliance

- Why choose steel toe boots over composite? For Maximum Impact Protection & Durability

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What types of workplaces are steel toe boots traditionally used in? Essential Foot Protection for Hazardous Jobs