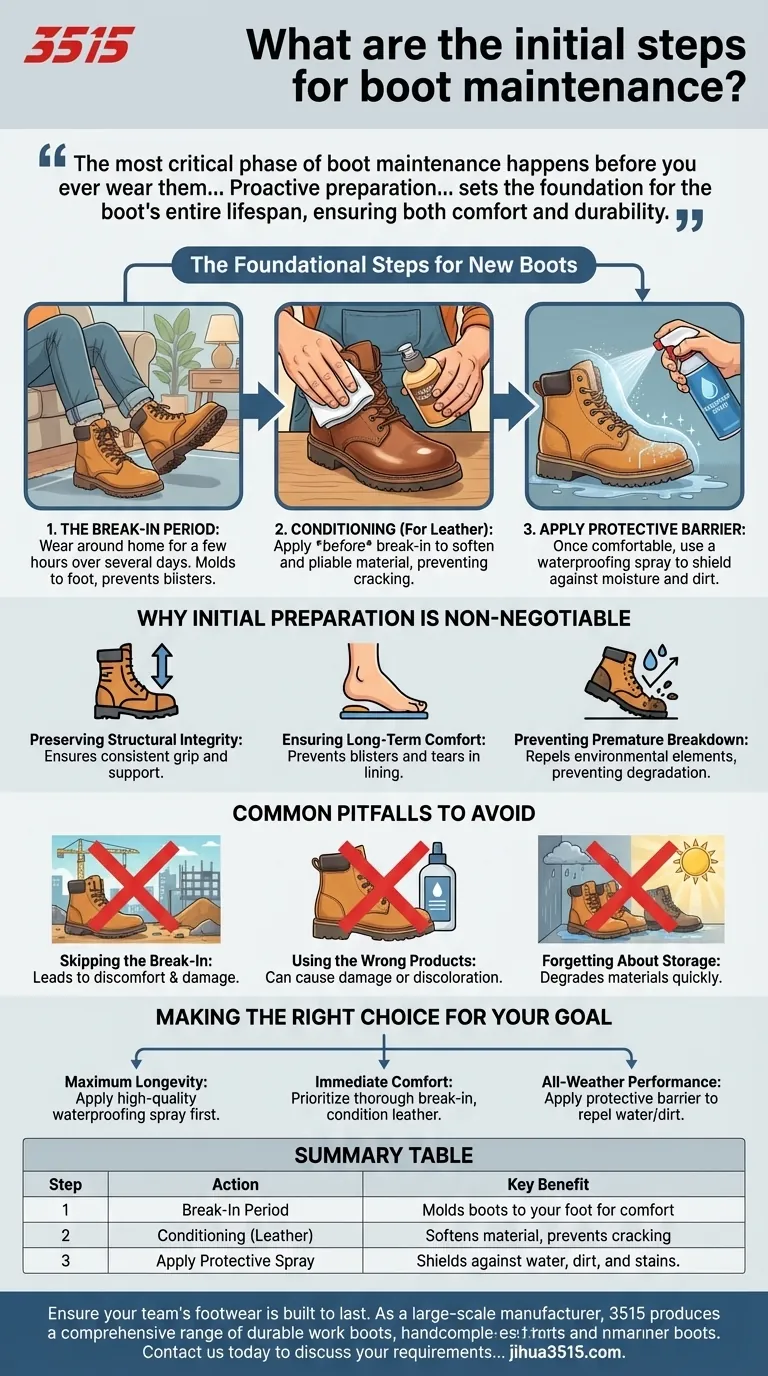

The initial steps for boot maintenance are breaking in the boots for comfort and applying a protective treatment before their first significant use. For new leather boots, this process should start with a quality conditioner to soften the material, followed by a gradual break-in period at home. Once they are comfortable, applying a waterproofing spray creates an essential barrier against moisture and dirt.

The most critical phase of boot maintenance happens before you ever wear them for their intended purpose. Proactive preparation—breaking them in and applying a protective shield—sets the foundation for the boot's entire lifespan, ensuring both comfort and durability.

Why Initial Preparation is Non-Negotiable

Proper care from day one is not about aesthetics; it is about preserving the core function and safety features of your footwear.

Preserving Structural Integrity

The primary goal of initial maintenance is to maintain the boot's intended design. This early care ensures the materials retain their ability to provide consistent grip, support, and protection over time.

Ensuring Long-Term Comfort

Skipping the initial steps is the primary cause of discomfort. A proper break-in period allows the boot to mold to your foot, preventing blisters and tears in the inner lining that can occur under immediate, heavy use.

Preventing Premature Breakdown

An untreated boot is immediately exposed to environmental damage. Applying a protective spray or conditioner creates an invisible barrier that repels water, dirt, and stains, preventing the material from degrading prematurely.

The Foundational Steps for New Boots

Follow this simple, three-step process to prepare any new pair of boots for a long service life.

Step 1: The Break-In Period

Before wearing your boots on a job site or for a full day, wear them around your home for a few hours at a time over several days. This gradually stretches and shapes the material to your foot without the stress of a full workday.

Step 2: Conditioning (For Leather)

If your boots are made of leather, apply a suitable leather conditioner before you begin the break-in process. This softens the stiff material, making it more pliable, comfortable, and less prone to cracking.

Step 3: Applying a Protective Barrier

Once the boots feel comfortable, apply a waterproofing or protective spray. Most modern sprays are effective on a wide range of materials, including leather, suede, nubuck, and textiles, providing a crucial first line of defense.

Common Pitfalls to Avoid

Many well-intentioned owners make simple mistakes that shorten the life of their boots. Understanding these common errors is key to effective maintenance.

Skipping the Break-In

The most common mistake is wearing new boots directly to work. This almost always leads to discomfort and can cause permanent damage to the boot's interior lining from excessive friction.

Using the Wrong Products

Not all conditioners or protective sprays are universal. Using a product not designed for your boot's specific material can cause discoloration, damage the material's texture, or fail to provide adequate protection.

Forgetting About Storage

How you store your boots is a form of passive maintenance. Leaving them in direct sunlight or a damp area can degrade materials far more quickly than active use. Always store them in a cool, dry place.

Making the Right Choice for Your Goal

Your initial maintenance focus should align with your primary objective for the boots.

- If your primary focus is maximum longevity: Your first action should be applying a high-quality waterproofing spray to shield the boots from environmental damage from day one.

- If your primary focus is immediate comfort: Prioritize a thorough break-in period, and for leather boots, use a conditioner before the first wear to soften the material.

- If your primary focus is all-weather performance: The most critical step is applying a protective barrier that repels water, which also has the secondary benefit of repelling dirt and stains.

Investing a small amount of time before the first wear dictates the performance and lifespan of your boots.

Summary Table:

| Step | Action | Key Benefit |

|---|---|---|

| 1 | Break-In Period | Molds boots to your foot for comfort |

| 2 | Conditioning (Leather) | Softens material, prevents cracking |

| 3 | Apply Protective Spray | Shields against water, dirt, and stains |

Ensure your team's footwear is built to last. As a large-scale manufacturer, 3515 produces a comprehensive range of durable work boots for distributors, brand owners, and bulk clients. Our expertise ensures your footwear is ready for action from day one. Contact us today to discuss your requirements and benefit from our extensive production capabilities.

Visual Guide

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Durable High-Traction Canvas Sneakers Wholesale & Custom Manufacturing

- Wholesale Smart Casual Sneakers with Dial Closure | Factory Direct Manufacturing

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

People Also Ask

- What organization sets national standards for workplace safety in the U.S.? OSHA's Role Explained

- What are the four key aspects to consider when choosing high-quality safety footwear? Ensure True Anatomical Fit & Protection

- How does ASTM differ from ANSI? Navigating the U.S. Standards System for Compliance

- How does toe box design differ between men's and women's work boots? Fit for a Woman's Foot Anatomy

- What regular maintenance checks should be performed on safety boots? A Daily Safety Checklist