Okay, here's what I'm thinking as I dive into this work boot sole analysis. First, I need to get straight to the point – the what – and then quickly get to the heart of the matter – the why. The user wants a definitive answer on work boot soles, but really, they need guidance to match the right sole to their specific work. Safety, comfort, and durability are clearly top of mind, so I need to address those head-on.

I see that the references offer a solid foundation. Thickness and traction are a given. The references on waterproof boots and safety toes, while not solely about the sole, highlight the larger safety context which is crucial. Riding boots provide a fantastic contrast; the requirements are so different! That helps me frame the "unique needs" angle. The tactical and winter boot examples are gold – they drive home the point that sole design is highly specialized and context-dependent. Slip resistance, oil resistance, and tread patterns need to be front and center.

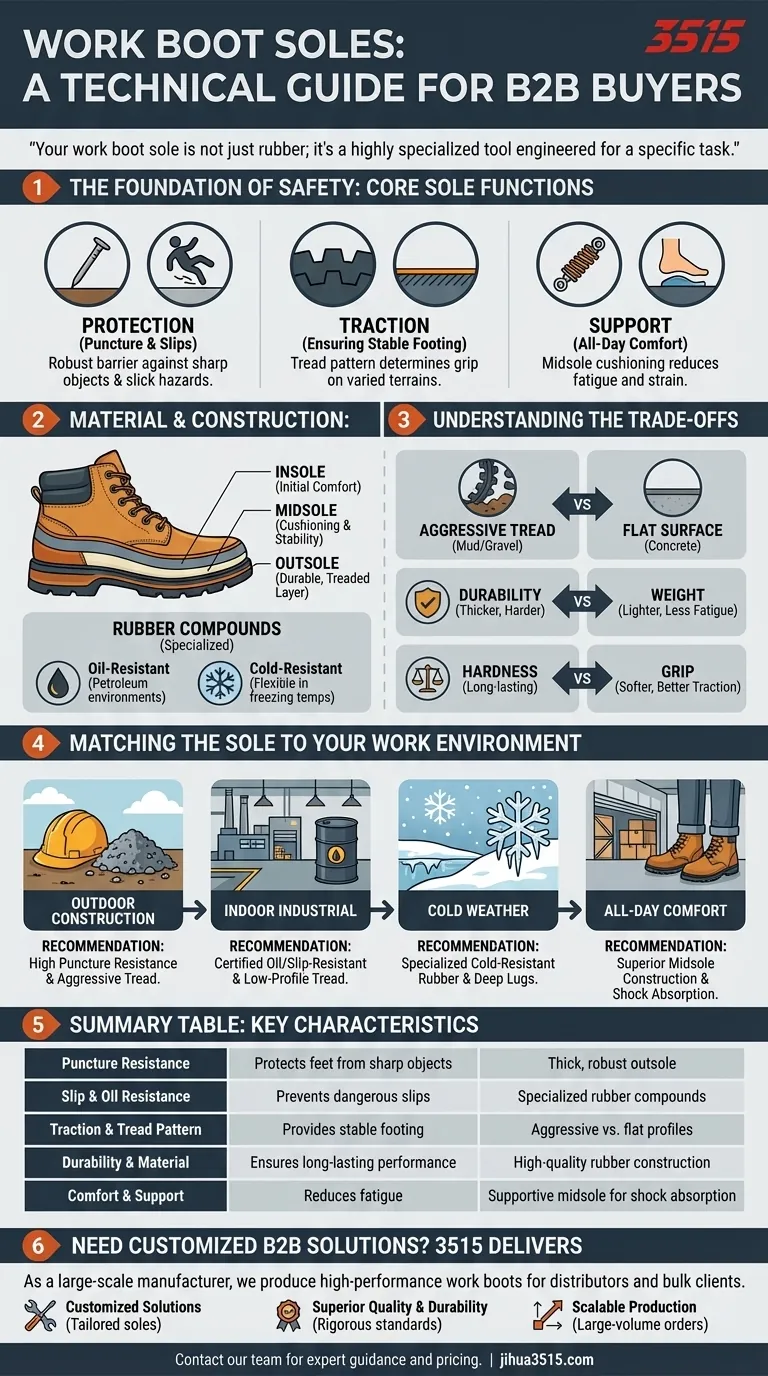

My structure will be key here. I'll open with a clear, concise answer: protection, traction, and durability are paramount, balanced with comfort. I'll then immediately frame the deep need – it's about matching the sole to the job. The body will build logically: First, the core functions: puncture resistance, slip prevention, and stable footing. Then, materials and construction: emphasizing rubber and its specialized compounds, plus the vital role of the midsole.

The "Trade-offs" section is critical for credibility. I'll explain how aggressive treads aren't always best, and durability comes with weight. It's not a simple equation. Finally, actionable advice! I'll provide clear recommendations based on work environments: construction, industrial, cold weather, and overall comfort. My goal is to empower the user to make an informed, safe, and effective choice. I want them to walk away feeling confident and secure in their selection. Ultimately, the best work boot sole is a direct match for your specific work environment. The most important characteristics are protection (from punctures and slips), traction (for grip on varied surfaces), and durability, all of which must be balanced to provide support and comfort throughout the day.

Your work boot's sole is not just a piece of rubber; it is a highly specialized tool engineered for a specific task. Understanding the core functions of material, tread, and construction is the only way to ensure you are choosing for maximum safety and performance, not just brand or style.

The Foundation of Safety: Core Sole Functions

A work boot sole serves as the critical interface between you and your work surface. Its primary job is to mitigate the specific hazards you face, which fall into three main categories.

Protection from Punctures and Slips

The sole is your first line of defense against ground-level threats. It must be thick and robust enough to resist punctures from nails, screws, and other sharp debris commonly found on job sites.

Equally important is slip resistance. High-quality soles are made from durable rubber compounds specifically formulated to resist slipping on common workplace hazards like water, oil, or chemicals. This is a non-negotiable safety feature in industrial or manufacturing environments.

Ensuring Stable Footing (Traction)

Traction is about how the sole grips the ground. This is determined by the tread pattern—the design of the grooves and channels on the bottom of the boot.

An aggressive tread with deep, prominent channels (lugs) is designed to bite into soft or uneven surfaces like mud, gravel, and snow. A less aggressive pattern provides more surface contact, which is better for smooth, flat surfaces like concrete or warehouse floors.

Providing All-Day Support

While the outer sole handles external hazards, the boot's internal structure—particularly the midsole—is responsible for comfort and support.

A well-designed sole system absorbs shock and distributes your weight evenly, preventing the fatigue and musculoskeletal strain that can result from standing or walking on hard surfaces for hours.

Material and Construction: What a Sole is Made Of

Not all soles are created equal. The materials and how they are put together dictate their performance in different conditions.

The Role of Rubber Compounds

Rubber is the standard material for work boot outsoles due to its excellent balance of durability, flexibility, and grip.

However, rubber can be engineered into specialized compounds. Oil-resistant soles prevent the rubber from breaking down after prolonged exposure to petroleum products. Cold-resistant compounds are designed to stay flexible and maintain grip in freezing temperatures, preventing the sole from becoming hard and slick.

Outsole, Midsole, and Insole

A boot's sole is a system of layers. The outsole is the durable, treaded layer that contacts the ground. The midsole sits above it, providing the primary cushioning and stability. The insole is the removable footbed inside the boot, offering initial comfort.

A robust outsole combined with a supportive midsole is the key to a boot that is both safe and comfortable for long-term wear.

Understanding the Trade-offs

Choosing the perfect sole involves balancing competing characteristics. An advantage in one environment can be a liability in another.

Aggressive Tread vs. Flat Surfaces

A sole with deep lugs designed for mud and gravel can be less stable on a smooth concrete floor. The deep channels reduce the amount of surface area in contact with the ground, potentially decreasing grip on flat, wet surfaces.

Durability vs. Weight

A thicker, harder, and more puncture-resistant sole is inherently heavier. While offering maximum protection, this added weight can contribute to foot and leg fatigue over an eight-hour workday. The goal is to find a sole that is protective enough for your risks without being unnecessarily heavy.

Hardness vs. Grip

A harder rubber compound will last significantly longer and better resist abrasion. However, it may offer less traction than a softer rubber compound, especially on smooth or wet surfaces. Softer rubber provides superior grip but will wear down much more quickly.

Matching the Sole to Your Work Environment

Use the specific demands of your job to guide your decision.

- If your primary focus is outdoor construction or landscaping: You need high puncture resistance and an aggressive tread pattern for excellent traction on uneven ground, mud, and gravel.

- If your primary focus is indoor industrial work (factories, workshops): Prioritize certified oil- and slip-resistant soles with a lower-profile tread for maximum surface contact on smooth, potentially slick floors.

- If your primary focus is cold weather or winter conditions: Look for soles made from specialized, cold-resistant rubber compounds and deep lugs designed specifically for snow and ice traction.

- If your primary focus is all-day comfort on hard surfaces: Pay close attention to the boot's midsole construction for superior cushioning and shock absorption, as this is more critical than the outsole tread.

By analyzing your environment first, you empower yourself to select a boot sole that functions as the perfect tool for the job.

Summary Table:

| Characteristic | Why It Matters | Key Feature |

|---|---|---|

| Puncture Resistance | Protects feet from sharp objects on the job site. | Thick, robust outsole material. |

| Slip & Oil Resistance | Prevents dangerous slips on wet or oily surfaces. | Specialized rubber compounds. |

| Traction & Tread Pattern | Provides stable footing on varied surfaces. | Aggressive lugs for mud/gravel; flat profile for concrete. |

| Durability & Material | Ensures long-lasting performance and value. | High-quality rubber and sturdy construction. |

| Comfort & Support | Reduces fatigue during long hours on your feet. | Supportive midsole for shock absorption. |

Need Work Boots with the Perfect Sole for Your Job?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance work boots for distributors, brand owners, and bulk clients. Our expertise in material science and production ensures every sole is engineered for its specific environment—from oil-resistant compounds for industrial floors to aggressive treads for outdoor construction.

We deliver:

- Customized Solutions: Soles tailored to your specific safety and comfort requirements.

- Superior Quality & Durability: Built to last with high-grade materials and rigorous standards.

- Scalable Production: Capabilities to meet large-volume orders efficiently.

Let's discuss how we can manufacture the right work boots for your market. Contact our team today for expert guidance and pricing.

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Why is investing in high-quality wildland firefighter boots important? Ensure Maximum Safety & Long-Term Value

- What are the characteristics of cowboy work boots? Discover the Hybrid of Style & Safety

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What should be considered when purchasing composite toe work boots? Ensure Safety, Comfort & Job-Site Fit

- How do moc toe boots differ from round-toe boots? A Guide to Rugged vs. Versatile Style

- What are the temperature ratings and recommended uses for 1,000g insulated boots? Stay Warm in Extreme Cold

- What are the advantages of full leather boots? Unmatched Durability & Long-Term Value

- What are insulated boots, and who should use them? Your Guide to Choosing the Right Warmth