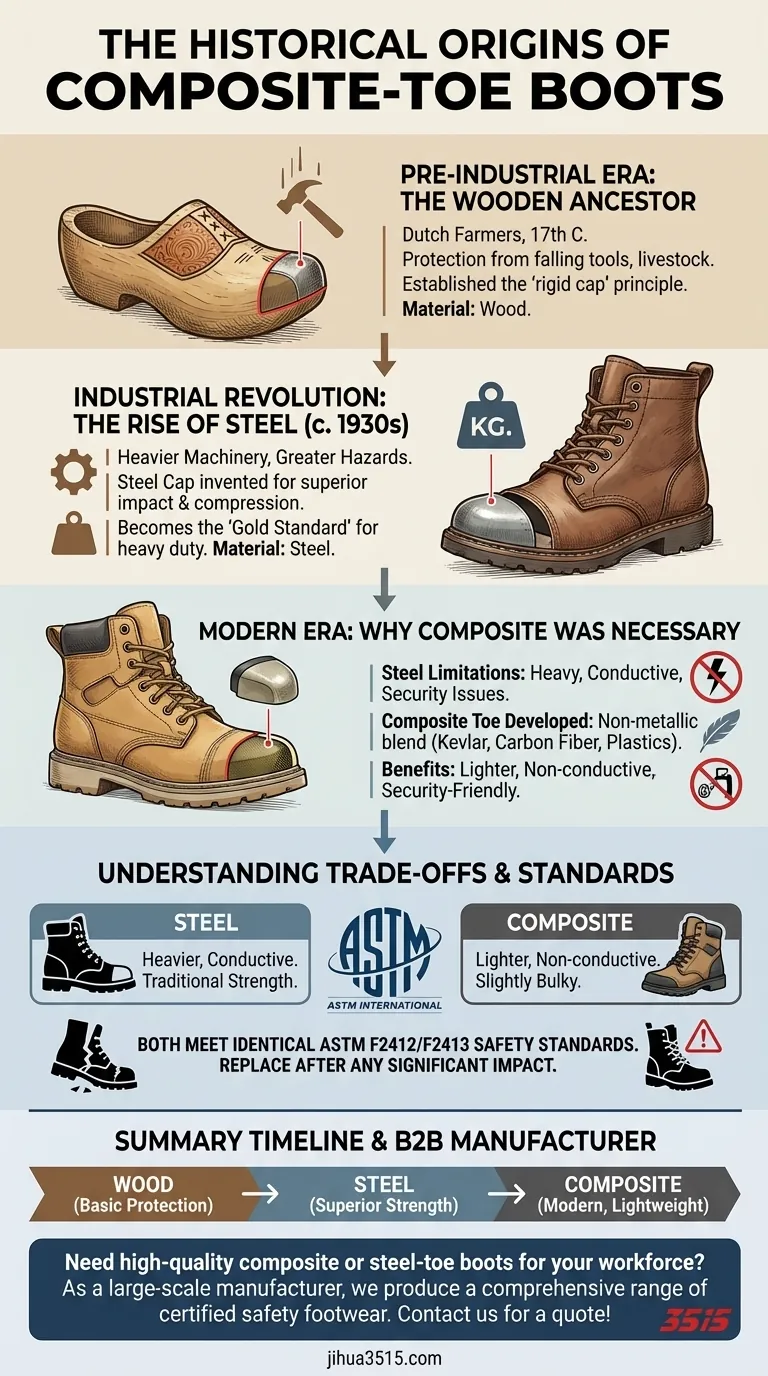

Historically, the concept behind composite-toe boots began not in a modern lab, but on farms. The earliest ancestor of a non-metallic protective shoe is the wooden clog, or "klomp," famously used by Dutch farmers to shield their feet from falling tools and the weight of livestock.

The evolution of safety footwear is a story of balancing protection with performance. While the steel toe set the standard for safety, the composite toe was developed to meet modern workplace demands for lighter, non-conductive, and more comfortable protection without compromising on certified safety standards.

The Original Safety Shoe: Wood Before Metal

The Dutch "Klomp" as Protective Gear

Long before industrial safety standards existed, workers relied on practical solutions. The Dutch wooden shoe was a prime example, carved from a single piece of willow or poplar wood.

Its primary function was protection. The rigid, solid shell acted as a primitive but effective safety toe, guarding against dropped objects, sharp tools, and animal hooves in agricultural and early industrial settings.

Establishing a Principle

This established the fundamental principle of safety footwear: a rigid cap is needed to protect the toes from impact and compression. The material itself was simply the best technology available at the time.

The Industrial Revolution and the Rise of Steel

A New Standard for Hazard Protection

The Industrial Revolution introduced heavier machinery and far greater workplace hazards. Wood was no longer a sufficient protective material against the new levels of risk found in factories, mines, and construction sites.

The Invention of the Steel Toe

In response, the steel-toe boot was developed around the 1930s. By inserting a steel cap into a standard work boot, manufacturers created a solution that offered vastly superior protection.

The Gold Standard for Decades

Steel became the undisputed benchmark for safety, capable of withstanding immense impact and compression forces. For many decades, it was the only option for heavy-duty foot protection and remains a trusted standard today.

The Modern Era: Why Composite Was Necessary

The Limitations of Steel

While incredibly effective, steel has inherent drawbacks. It is heavy, which causes fatigue over a long workday. It also readily conducts temperature, making boots cold in the winter and hot in the summer.

Crucially, steel's conductivity poses two modern problems: it can conduct electricity, creating a hazard in certain environments, and it will set off metal detectors, a major inconvenience for workers in secure facilities.

The Emergence of Composite Materials

The composite toe was engineered specifically to solve these problems. It is not one single material, but a non-metallic blend of advanced materials like Kevlar, carbon fiber, fiberglass, and specialized plastics.

Solving Steel's Shortcomings

This combination of materials creates a safety toe that is significantly lighter than steel, does not conduct heat or electricity, and is "security friendly." It provides a modern alternative for workers who need certified protection without the downsides of metal.

Understanding the Trade-offs

Meeting Identical Safety Standards

It is a common misconception that one material is inherently safer than the other. Both steel-toe and composite-toe boots must meet the exact same ASTM International (F2412/F2413) safety standards for impact and compression resistance to be sold as protective footwear.

Bulk and Design

To achieve the same level of protection as thin, strong steel, a composite toe cap often needs to be slightly thicker or bulkier. This can sometimes affect the profile or fit of the boot, though modern designs have minimized this difference.

Performance After Impact

After a single, significant impact, any safety-toe boot—whether steel or composite—should be replaced. Its protective capabilities are compromised once the structure has been crushed or damaged.

Making the Right Choice for Your Work

Choosing between steel and composite depends entirely on the specific demands of your job and environment.

- If your primary focus is work in heavy industry with extreme drop hazards (logging, heavy manufacturing): Steel is often the traditional and trusted choice, known for its sheer strength.

- If your primary focus is protection from electrical hazards or working in extreme temperatures: Composite is the definitive and superior choice due to its non-conductive properties.

- If your primary focus is comfort, reducing fatigue, or passing through metal detectors: Composite is the clear winner for its lightweight, security-friendly design.

Ultimately, both materials represent a critical evolution from their wooden ancestor, providing certified protection tailored to the unique challenges of the modern worker.

Summary Table:

| Era | Key Development | Material | Primary Benefit |

|---|---|---|---|

| Pre-Industrial | Wooden Clogs (Klomp) | Wood | Basic impact protection |

| 1930s | Invention of Steel Toe | Steel | Superior protection for heavy industry |

| Modern Era | Development of Composite Toe | Kevlar, Fiberglass, Plastics | Lightweight, non-conductive, security-friendly |

Need high-quality composite-toe or steel-toe boots for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your team needs the lightweight comfort of composite toes or the traditional strength of steel, we have the production capabilities and expertise to meet your demands.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- How does the structural design of industrial-grade safety shoes provide protection? Engineering Foot Health at Work

- What protective functions do safety shoes provide in construction safety? Maximize Site Safety and Reduce Downtime

- Why are safety shoes mandatory for historical stone cleaning? Essential Gear for Restoration Projects

- How do safety shoes protect workers in precast concrete production? Essential Steel Toe and Midsole Protection Guide

- What are the requirements for a protective toe cap? Meet ASTM F2413 Standards for Maximum Safety