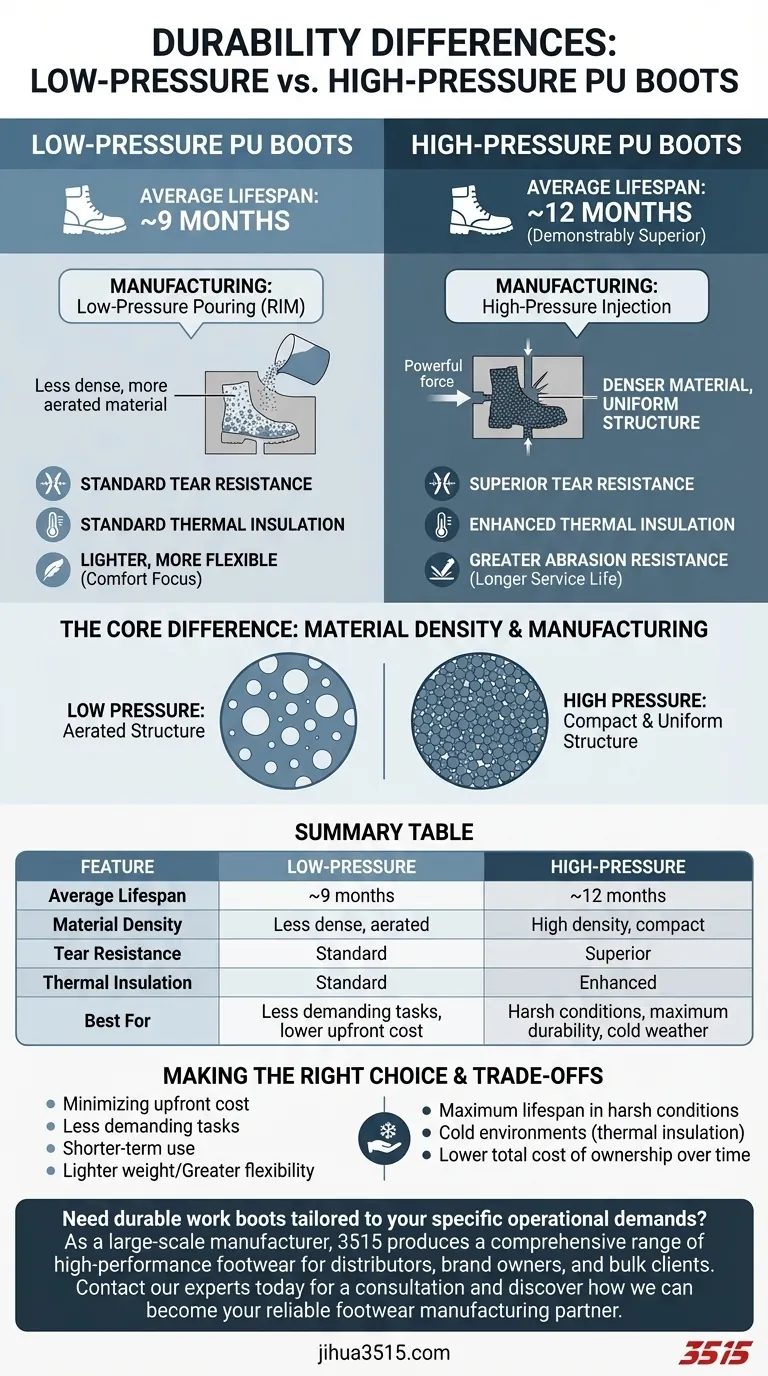

In terms of raw durability, high-pressure polyurethane (PU) boots demonstrably outperform their low-pressure counterparts. On average, a high-pressure PU boot lasts approximately 12 months, whereas a low-pressure version typically lasts around nine months. This extended lifespan is a direct result of the manufacturing process, which gives high-pressure boots superior tear resistance and thermal insulation.

The core difference lies in material density. High-pressure injection molding creates a more compact and uniform polyurethane structure, leading to enhanced physical properties and a longer service life compared to the lighter, more aerated structure of low-pressure PU.

The Core Difference: Manufacturing and Density

To understand why one boot lasts longer than the other, you must first understand how they are made. The distinction in pressure during the manufacturing process is not a minor detail; it fundamentally changes the physical structure of the final product.

High-Pressure Injection

High-pressure manufacturing uses significant force to inject the liquid polyurethane mixture into a sealed mold. This process ensures the material fills every cavity completely and uniformly.

The primary result is a denser material with a more tightly packed molecular structure. There are fewer microscopic voids or air pockets, creating a solid, homogenous final product.

Low-Pressure Pouring

Low-pressure methods, often called reaction injection molding (RIM) or open-pour, involve a gentler process. The PU mixture is poured or injected with much less force into a mold.

This results in a less dense, more aerated material. While still a durable foam, its internal structure is less compact than that of its high-pressure equivalent.

Key Performance Differences Explained

The difference in material density created during manufacturing directly translates into tangible performance characteristics that affect the boot's daily use and longevity.

Lifespan and Abrasion Resistance

The 12-month average lifespan of high-pressure boots versus the 9-month lifespan of low-pressure boots is a direct function of abrasion resistance. The denser material simply has more substance to wear away, resisting the scuffs, scrapes, and general wear of a demanding environment for a longer period.

Tear Resistance

High-pressure PU offers significantly better tear resistance. Its uniform, non-porous structure helps prevent small nicks or cuts from propagating into larger, boot-compromising tears. This is critical in environments with sharp objects or rough surfaces.

Thermal Insulation

The superior thermal insulation of high-pressure PU is also a result of its density. The compact material creates a more effective barrier against thermal transfer, better protecting the wearer's feet from cold ground or ambient temperatures.

Understanding the Trade-offs

While high-pressure PU offers clear advantages in durability, the choice is not always straightforward. There are important trade-offs to consider based on your specific application and priorities.

Initial Cost vs. Total Cost of Ownership

High-pressure manufacturing is a more complex and energy-intensive process, which often translates to a higher initial purchase price for the boots. However, their longer lifespan can result in a lower total cost of ownership over time, as they require less frequent replacement.

Weight and Flexibility

The lower density of low-pressure PU boots often makes them lighter and potentially more flexible. For users in less demanding roles where all-day comfort and minimizing fatigue are the highest priorities, a low-pressure boot might feel more comfortable out of the box.

Making the Right Choice for Your Application

Ultimately, the right boot depends entirely on the demands of your environment and your primary goals.

- If your primary focus is maximum lifespan in harsh conditions: Choose high-pressure PU boots for their superior tear resistance and overall durability.

- If your primary focus is performance in cold environments: The enhanced thermal insulation of high-pressure PU makes it the definitive choice for cold-weather work.

- If your primary focus is minimizing upfront cost for less demanding tasks: Low-pressure PU boots provide a serviceable and more economical option for shorter-term or less intensive use cases.

By understanding how manufacturing pressure dictates material density, you can confidently select the boot that delivers the right balance of performance and value for your needs.

Summary Table:

| Feature | Low-Pressure PU Boots | High-Pressure PU Boots |

|---|---|---|

| Average Lifespan | ~9 months | ~12 months |

| Material Density | Less dense, aerated | High density, compact |

| Tear Resistance | Standard | Superior |

| Thermal Insulation | Standard | Enhanced |

| Best For | Less demanding tasks, lower upfront cost | Harsh conditions, maximum durability, cold weather |

Need durable work boots tailored to your specific operational demands?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities ensure we can deliver the exact balance of durability, comfort, and value your team requires—whether you need the superior longevity of high-pressure PU or the cost-effective solution of low-pressure boots.

Contact our experts today for a consultation and discover how we can become your reliable footwear manufacturing partner.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- What specific mechanical protections do industrial safety shoes provide in cable factories? Expert Guide for Max Safety