Ultimately, the drawbacks of Goodyear Welt construction are the direct result of its greatest strengths. This method produces a heavier, more rigid, and more expensive shoe due to the complex, multi-layered process that makes it exceptionally durable and easy to resole. The initial break-in period can be significant, and the shoe will feel less flexible than those made with more streamlined construction methods.

While considered the gold standard for high-quality, long-lasting footwear, Goodyear Welt construction is a deliberate trade-off. It prioritizes long-term durability and repairability over initial, out-of-the-box comfort, flexibility, and affordability.

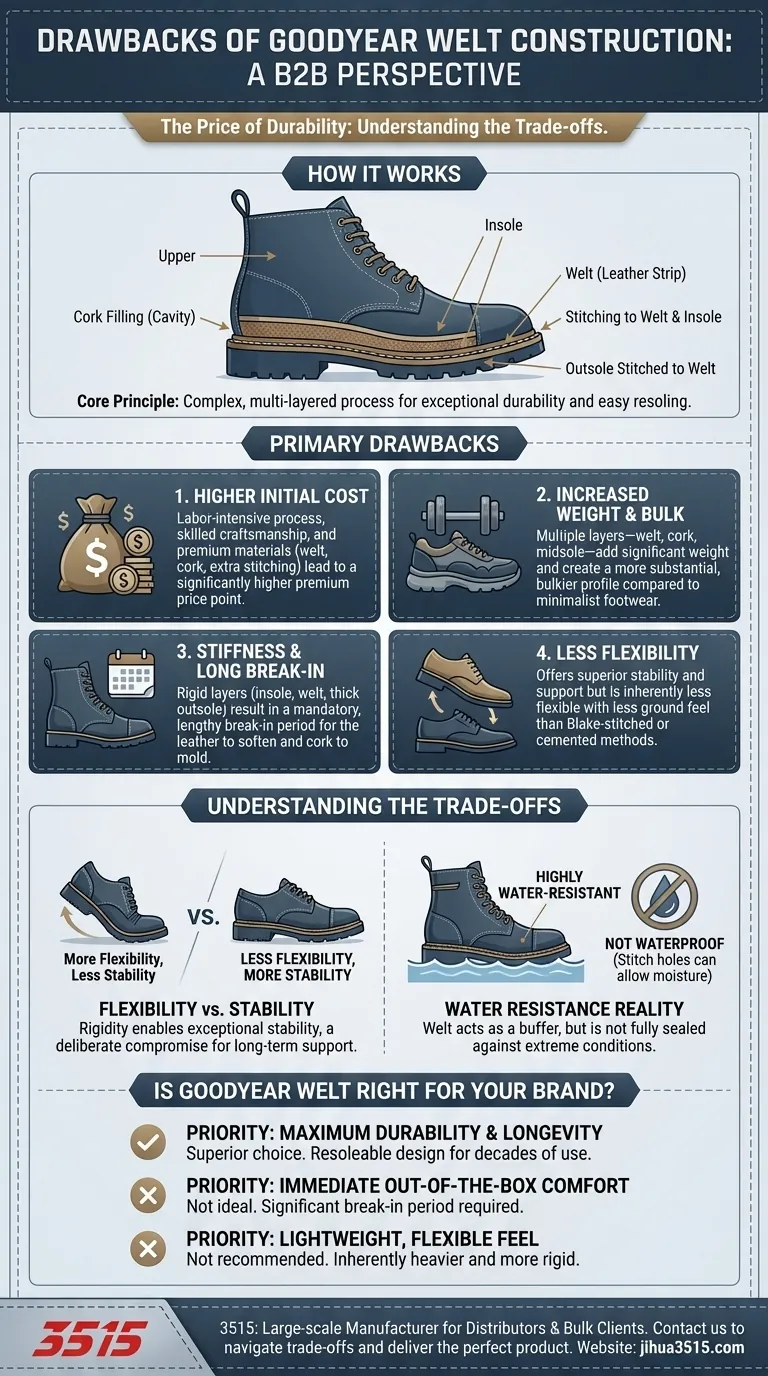

The Core Principle of Goodyear Welt

To understand the drawbacks, you must first understand the design. The Goodyear Welt is prized not for how it feels on day one, but for how it performs over decades.

How It Works

A strip of leather, known as the welt, is stitched to the shoe's upper and insole. This creates a distinct cavity between the insole and the outsole.

This cavity is then filled with a material, typically cork, which provides some cushioning and insulation. Finally, the outsole is stitched directly to the welt, rather than to the upper itself.

The Intended Benefit: Longevity

This construction method creates an incredibly strong bond that is also easy to deconstruct. When the sole wears out, a cobbler can simply cut the stitches holding the outsole to the welt and attach a new one.

This resoleability is the primary advantage, allowing the shoe's lifespan to be extended multiple times, far beyond the life of the original sole.

Unpacking the Primary Drawbacks

The very features that make a Goodyear Welted shoe so robust also introduce its main disadvantages.

Higher Initial Cost

The process is time-consuming, requires more materials (the welt, cork filling, extra stitching), and demands skilled craftsmanship.

This intricate, labor-intensive construction directly translates to a higher premium price point compared to simpler methods like cementing (gluing) soles.

Increased Weight and Bulk

The addition of the leather welt, a midsole, and the cork filling creates extra layers between your foot and the ground.

These components add significant weight and create a more substantial, bulkier shoe profile. They are the opposite of lightweight or minimalist footwear.

Stiffness and a Long Break-in Period

The multiple rigid layers—a sturdy leather insole, the welt, and a thick outsole—make the shoe very stiff when new.

This results in a mandatory and often lengthy break-in period. The shoe requires wear for the leather to soften and the cork footbed to compress and mold to the shape of your foot.

Understanding the Trade-offs

Choosing a Goodyear Welted shoe means accepting certain compromises in exchange for its renowned durability.

Flexibility vs. Stability

The rigidity that causes the challenging break-in period also provides exceptional stability and support.

A Goodyear Welted shoe is less flexible and offers less "ground feel" than a Blake-stitched or cemented shoe, but it provides a more solid and supportive platform.

The Reality of Water Resistance

The welt acts as a buffer, preventing water from easily seeping in at the seam between the upper and the sole. This makes the construction highly water-resistant.

However, it is not completely waterproof. The stitch holes through the welt can still allow moisture to penetrate under extreme conditions, unlike a fully sealed construction.

Insulation and Comfort

The cork filling provides a modest amount of insulation from the ground. Over time, it molds to your foot, creating a custom-like fit that many find exceptionally comfortable.

This long-term, customized comfort is achieved only after enduring the initial stiffness of the break-in period.

Is Goodyear Welt the Right Choice for You?

Selecting a shoe construction method depends entirely on your priorities.

- If your primary focus is maximum durability and longevity: Goodyear Welt is the superior choice, as its resoleable design allows the footwear to last for decades with proper care.

- If your primary focus is immediate, out-of-the-box comfort: You may prefer a different construction, as the required break-in period for a Goodyear Welt can be substantial.

- If your primary focus is a lightweight, flexible feel: This construction is likely not the best option, as it is inherently heavier and more rigid than alternatives.

Understanding these trade-offs empowers you to invest in footwear that truly aligns with your needs, whether for uncompromising durability or for immediate comfort and flexibility.

Summary Table:

| Drawback | Description |

|---|---|

| Higher Cost | Labor-intensive process and premium materials lead to a higher price point. |

| Increased Weight & Bulk | Multiple layers (welt, cork, midsole) create a heavier, more substantial shoe. |

| Stiffness & Long Break-in | Rigid construction requires a significant period to soften and mold to your foot. |

| Less Flexibility | Offers superior stability but less flexibility and ground feel than other methods. |

Need durable, high-quality footwear for your business or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear Welted and other constructed footwear for distributors, brand owners, and bulk clients. We can help you navigate these trade-offs to deliver the perfect product for your market.

Contact our team today to discuss your production needs and leverage our expertise in all types of shoes and boots.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries