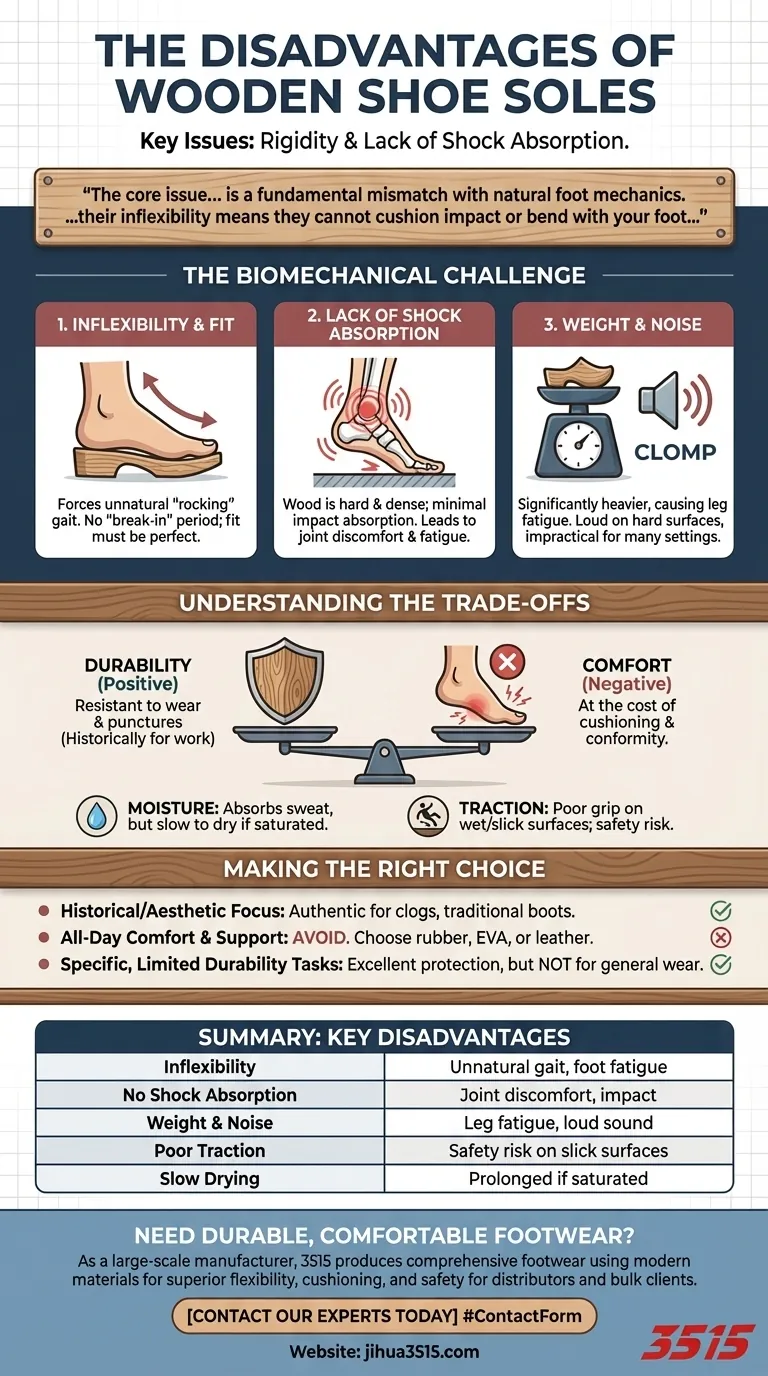

In short, the primary disadvantages of wooden shoe soles are their rigidity and lack of shock absorption. Unlike flexible materials that adapt to your foot's movement, a wooden sole forces your foot to conform to its unchanging shape. This can lead to significant discomfort and an unnatural walking gait if the fit is not perfect from the very beginning.

The core issue with wooden soles isn't just a lack of comfort; it's a fundamental mismatch with natural foot mechanics. While durable, their inflexibility means they cannot cushion impact or bend with your foot, creating a wearing experience that is often tiring and unforgiving.

The Biomechanical Challenge of Wooden Soles

Wooden soles have a long history, valued for their durability and protection. However, their physical properties present several distinct disadvantages compared to modern sole materials like rubber, leather, or synthetics.

Inflexibility and Fit

The most significant drawback is the complete lack of flexibility. A wooden sole does not bend at the ball of the foot during the push-off phase of walking.

This forces an unnatural "rocking" motion, which can feel awkward and fatiguing. Because the wood will not "break in" or mold to your foot's unique shape, an imperfect initial fit will never improve.

Lack of Shock Absorption

Wood is a hard, dense material with minimal ability to absorb impact. Every step you take on a hard surface like pavement sends a direct shock up through your feet, ankles, and knees.

This lack of cushioning can lead to joint discomfort and fatigue, especially during prolonged periods of walking or standing. Modern footwear is explicitly designed to mitigate this, a feature that wood fundamentally lacks.

Weight and Noise

Wooden soles are noticeably heavier than most alternatives. This added weight contributes to leg fatigue over the course of a day.

They are also loud, producing a distinct "clomping" sound on hard surfaces. While this can be a stylistic choice (as with clogs), it is often impractical or undesirable in many social and professional settings.

Understanding the Trade-offs

Choosing a wooden sole involves accepting a specific set of compromises in exchange for durability and a unique aesthetic.

Durability vs. Comfort

Wood is exceptionally durable and resistant to wear and punctures. This is why it was historically used for work shoes.

However, this durability comes at the direct cost of comfort. The material that resists wear and tear is the same material that resists conforming to your foot and cushioning your stride.

Moisture Management

One of the few functional benefits of unfinished wood is its ability to absorb moisture. It can naturally wick sweat away, keeping feet relatively dry and helping to reduce odor.

Yet, this is a double-edged sword. If the shoes become saturated from external water, they can take a very long time to dry out, unlike more modern materials.

Traction and Safety

While some traditional wooden shoes have carved treads, many have a smooth surface that offers poor grip on slick or wet surfaces.

This can pose a safety risk, especially when compared to the engineered tread patterns and high-friction compounds found in rubber or synthetic soles.

Making the Right Choice for Your Goal

Ultimately, the suitability of wooden soles depends entirely on your intended use and priorities.

- If your primary focus is historical accuracy or a specific aesthetic: Wooden soles are an authentic and necessary choice for traditional footwear like clogs or certain types of boots.

- If your primary focus is all-day comfort and ergonomic support: You should avoid wooden soles and opt for modern materials like rubber, EVA foam, or leather that provide flexibility and cushioning.

- If your primary focus is durability for specific, limited tasks: A well-fitted wooden-soled work shoe can offer excellent protection, but it will not be a comfortable option for general wear.

Consider wooden-soled footwear as a specialized tool, not an everyday comfort staple.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Inflexibility | Unnatural gait, foot fatigue, no break-in period |

| No Shock Absorption | Joint discomfort, impact on knees and ankles |

| Weight & Noise | Leg fatigue, loud 'clomping' sound |

| Poor Traction | Safety risk on slick or wet surfaces |

| Slow Drying | Prolonged drying time if saturated |

Need durable, comfortable footwear without the drawbacks of wood?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, using modern materials that provide superior flexibility, cushioning, and safety. We can help you find or create the perfect shoe solution for your market.

Contact our experts today to discuss your needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Leather Ankle Boots with Lug Soles for Custom Brand Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What is the function of an industrial internal mixer for high-slip rubber outsoles? Master the Foundation of Durability

- What are the characteristics of Resin Rubber soles? Durable, Waterproof & Firm

- What is the function of a portable surface roughness tester in rubber tribology experiments for the footwear industry? Ensuring Accurate Slip Resistance & Safety

- What are the environmental benefits of rubber soles? Renewable, Durable & Sustainable

- Which type of boot is more suitable for extended use and why? Choose Rubber for All-Day Comfort

- How have synthetic materials affected rubber usage in shoes? A Guide to Modern Footwear Materials

- Which sole materials are recommended for dry tile floors? Ensure Maximum Grip and Stability

- What are the main components created during the shoe sole manufacturing process? Insole, Midsole, and Outsole Explained