Under the EN ISO 20345 standard, safety shoes are categorized into distinct ratings, primarily S1, S1P, S2, S3, S4, and S5, each indicating a specific set of protective features beyond the mandatory toe cap. These classifications ensure that footwear provides appropriate protection against various workplace hazards, from basic impact and compression to advanced water resistance and puncture protection.

The EN ISO 20345 standard provides a clear framework for safety footwear, classifying shoes into categories like S1, S1P, S2, S3, S4, and S5. Each rating builds upon the previous, offering a precise way to match shoe protection features—such as toe caps, anti-puncture midsoles, and water resistance—to the specific risks present in diverse work environments.

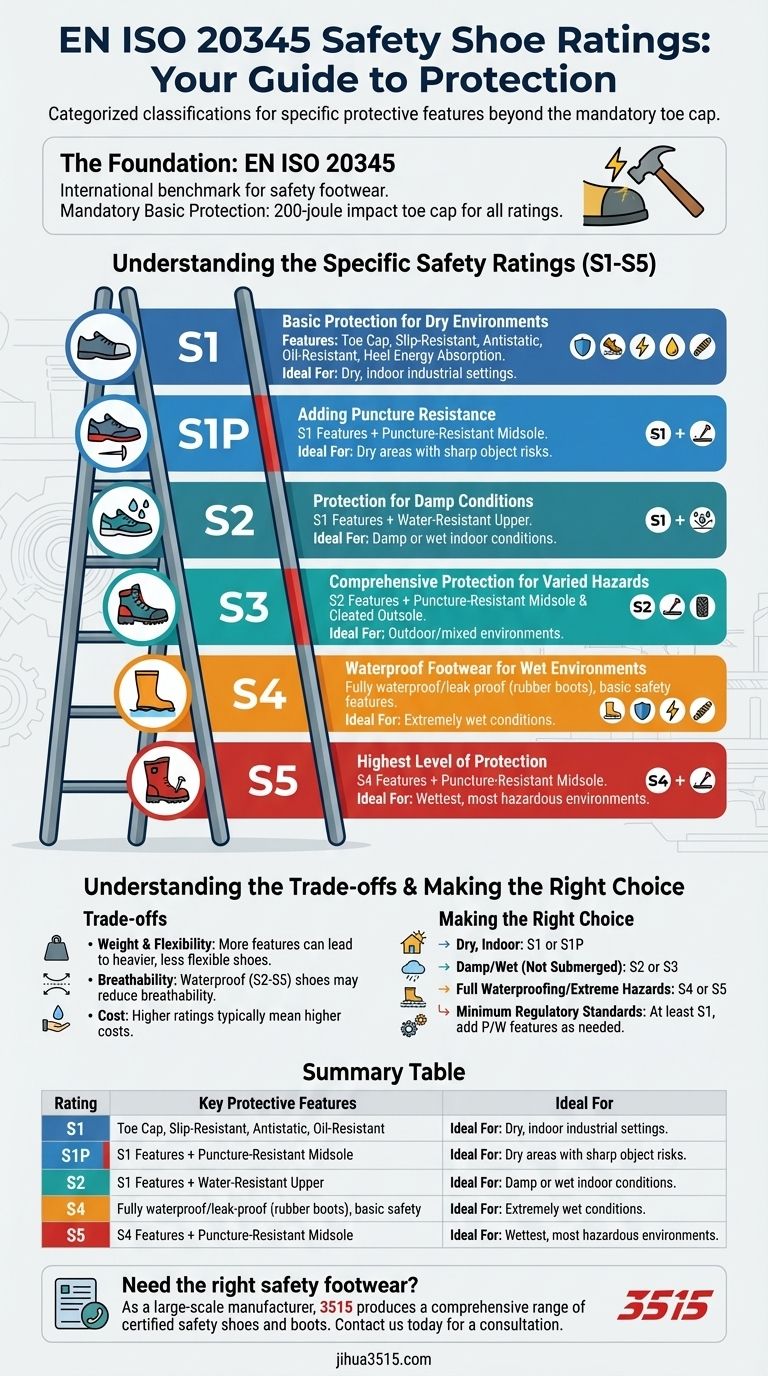

The Foundation of Safety Footwear: EN ISO 20345

The EN ISO 20345 standard is the international benchmark for safety footwear. It sets minimum requirements that all safety shoes must meet to be certified. This standard ensures consistent levels of protection across various manufacturers.

Mandatory Basic Protection

All safety shoes certified under EN ISO 20345 share a fundamental protective feature. This includes front foot protection designed to withstand a 200-joule impact. This level of energy absorption protects the toes from significant impacts and compression.

Understanding the Specific Safety Ratings

The "S" categories (S1 through S5) define additional protective features layered onto the basic 200-joule toe cap. These categories address different workplace hazards and environmental conditions.

S1: Basic Protection for Dry Environments

S1 rated safety shoes are suitable for lighter industrial environments without significant water exposure. They include toe cap protection, slip-resistant soles, antistatic properties, oil resistance, and energy absorption in the heel. This makes them ideal for indoor settings where standing for long periods is common.

S1P: Adding Puncture Resistance

S1P shoes build upon the S1 classification. They add an essential feature: a puncture-resistant midsole. This protects against sharp objects underfoot, such as nails or glass.

S2: Protection for Damp Conditions

S2 rated footwear incorporates all the features of S1. Crucially, S2 shoes also feature a water-resistant exterior. This means the upper material is treated to resist water penetration, keeping feet dry in damp conditions.

S3: Comprehensive Protection for Varied Hazards

S3 safety shoes offer comprehensive protection, combining the features of S2. They include a puncture-resistant midsole and cleated outsoles for enhanced slip resistance. S3 is a very common rating for outdoor or mixed environments with multiple hazards.

S4: Waterproof Footwear for Wet Environments

S4 rated safety shoes are typically made from rubber or entirely molded polymer. They are completely waterproof and leak-proof, offering robust protection in extremely wet conditions. S4 shoes inherently include the basic safety features like toe cap protection, antistatic properties, and energy absorption in the heel.

S5: Highest Level of Protection

S5 is the highest safety rating under EN ISO 20345. It encompasses all the protective elements of S4 and adds a puncture-resistant midsole. This provides ultimate protection against both water and penetration risks in the wettest and most hazardous environments.

Understanding the Trade-offs

While higher ratings offer more protection, they can sometimes come with specific trade-offs. It's crucial to balance protection with comfort and specific job requirements.

Weight and Flexibility

Footwear with more protective features, like steel midsoles and waterproof membranes, can be heavier and less flexible. This might impact comfort for jobs requiring extensive movement.

Breathability

Waterproof shoes (S2, S3, S4, S5) often have reduced breathability compared to S1 or S1P shoes. This can lead to increased perspiration in warmer environments.

Cost

Generally, higher safety ratings correlate with higher manufacturing costs. This can influence procurement decisions for large teams.

Making the Right Choice for Your Goal

Selecting the correct safety shoe rating is critical for ensuring worker safety and compliance. Consider the specific hazards of the work environment.

- If your primary focus is basic protection in dry, indoor settings: Opt for S1 or S1P to protect against impacts and potentially punctures.

- If your primary focus is protection in damp or wet, but not fully submerged, conditions: Choose S2 or S3 for water resistance, with S3 adding puncture protection.

- If your primary focus is full waterproofing and extreme hazard protection: Select S4 or S5 for environments with standing water, with S5 providing critical puncture resistance.

- If your primary focus is to meet minimum regulatory standards for general industrial work: Ensure the footwear meets at least S1 and add features like puncture resistance (S1P, S3, S5) or water resistance (S2, S3, S4, S5) as needed for specific hazards.

Understanding these ratings empowers you to provide optimal protection, enhancing safety and productivity in any work environment.

Summary Table:

| Rating | Key Protective Features | Ideal For |

|---|---|---|

| S1 | Basic toe cap, slip-resistant, antistatic, oil-resistant | Dry, indoor industrial settings |

| S1P | S1 features + Puncture-resistant midsole | Dry areas with sharp object risks |

| S2 | S1 features + Water-resistant upper | Damp or wet indoor conditions |

| S3 | S2 features + Puncture-resistant midsole & cleated outsole | Outdoor/mixed environments with multiple hazards |

| S4 | Fully waterproof/leak-proof (e.g., rubber boots), basic safety features | Extremely wet conditions |

| S5 | S4 features + Puncture-resistant midsole | Wettest, most hazardous environments |

Need the right safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. We can produce any type of safety footwear—from basic S1 to the highest S5-rated boots—ensuring your workers have the precise protection they need.

Contact us today for a consultation to discuss your specific requirements and benefit from our extensive production capabilities and expertise.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

People Also Ask

- What is the recommended PPE for hazmat situations? Ensure Safety with Chemical-Resistant Protection

- What does a blue rectangle symbol on safety footwear mean? Decode CSA Protection Symbols

- What primary protective functions do industrial safety shoes provide for personnel working on an airport apron?

- What are the differences between water-resistant and waterproof work shoes? Choose the Right Protection for Your Job

- What are the technical advantages of industrial-grade slip-resistant safety shoes? Prevent Falls with Engineered Grip

- What are the benefits of waterproofing liners in safety shoes? Achieve Superior Foot Protection & Comfort

- Why is the structural design of safety and tactical boots important? Protect Your Joints and Prevent Knee Collapse

- How safety and reliability impact protective footwear marketing vs. status attributes? Elevate Security over Image