For hazardous materials (Hazmat) situations, the recommended personal protective equipment (PPE) consists of disposable chemical-resistant coveralls (such as Tyvek), rubber overboots, and nitrile or latex gloves. While this constitutes the baseline for contamination control, higher-level threats involving toxic vapors or corrosives require specialized Level A or Level B chemical protective suits.

The Core Insight Structural turnout gear is engineered for thermal protection and breathability, making it dangerously porous to chemicals. To ensure safety in Hazmat scenarios, you must prioritize impermeability and disposability over thermal resistance, scaling your protection level to match the specific chemical threat.

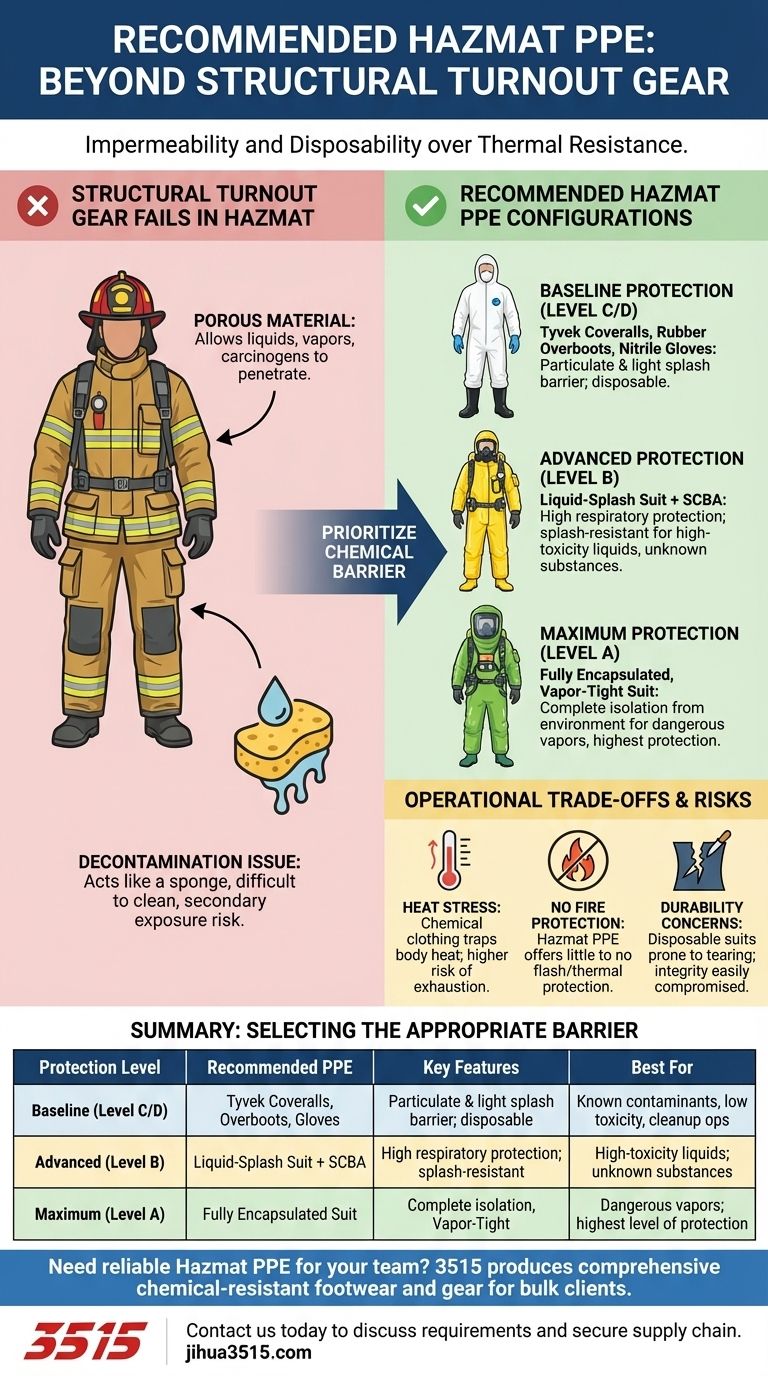

Why Structural Turnout Gear Fails in Hazmat

The Porosity Trap

Structural firefighting gear is designed to "breathe" to manage metabolic heat.

Unfortunately, this porosity allows liquids, vapors, and carcinogens to penetrate the material and reach the skin.

The Decontamination Issue

Turnout gear acts like a sponge for hazardous agents.

Once contaminated, it is incredibly difficult to clean thoroughly. This leads to secondary exposure risks for the wearer and potential cross-contamination of apparatus and living quarters.

Recommended Hazmat PPE Configurations

Baseline Protection (Level C/D)

For known contaminants with low toxicity or simple cleanup operations, disposable Tyvek coveralls are the standard.

These create a physical barrier against particulates and light liquid splashes.

Foot and Hand Protection

Leather structural boots and gloves absorb chemicals and should be replaced.

Rubber overboots are essential to prevent chemicals from soaking into footwear. Similarly, nitrile or latex gloves (often double-gloved) provide necessary chemical resistance that leather cannot offer.

Advanced Protection (Level A and B)

When the hazard involves high toxicity, unknown substances, or dangerous vapors, basic coveralls are insufficient.

Level B suits provide the highest level of respiratory protection (SCBA) with liquid-splash resistance.

Level A suits are fully encapsulated and vapor-tight, isolating the wearer completely from the environment.

Operational Trade-offs and Risks

Heat Stress Management

Chemical protective clothing, especially rubber and Tyvek, does not breathe.

This traps body heat rapidly, significantly increasing the risk of heat exhaustion compared to breathable structural gear, even with less physical exertion.

Lack of Thermal/Flash Protection

It is critical to remember that standard Hazmat PPE (Tyvek, Level A/B suits) offers little to no protection against fire.

If a flammability risk exists alongside a chemical risk, specialized "flash protection" suits are required, or the strategy must be altered to avoid the hot zone.

Durability Concerns

Disposable suits are prone to tearing and snagging.

Unlike rugged turnout gear, a single nail or sharp edge can compromise the integrity of a Tyvek suit, breaching your protective barrier immediately.

Selecting the Appropriate Barrier

Before committing to a PPE ensemble, assess the physical state of the contaminant.

- If your primary focus is particulate or light splash protection: Utilize disposable Tyvek coveralls with rubber overboots and nitrile gloves to ensure easy decontamination.

- If your primary focus is high-toxicity liquids or unknown vapors: You must upgrade to Level A or B encapsulated suits to prevent respiratory and skin absorption.

The goal is to create an impermeable barrier that keeps the hazard on the suit, not on the responder.

Summary Table:

| Protection Level | Recommended PPE | Key Features | Best For |

|---|---|---|---|

| Baseline (Level C/D) | Tyvek Coveralls, Rubber Overboots, Nitrile Gloves | Particulate & light splash barrier; disposable | Known contaminants, low toxicity, cleanup ops |

| Advanced (Level B) | Liquid-Splash Suit + SCBA | High respiratory protection; splash-resistant | High-toxicity liquids; unknown substances |

| Maximum (Level A) | Fully Encapsulated, Vapor-Tight Suit | Complete isolation from environment | Dangerous vapors; highest level of protection |

Need reliable Hazmat PPE for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of chemical-resistant footwear and protective gear for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, effective protection tailored for hazardous environments.

Contact us today to discuss your specific Hazmat PPE requirements and secure your supply chain.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why is choosing the right safety shoes important? Mitigate Workplace Hazards and Boost Productivity

- What are the standard European classifications for safety footwear? A Guide to EN ISO 20345

- What is the importance of using standardized measurement tools in the quality assessment of safety footwear? Key Benefits

- What are the advantages of alloy toe boots? Lighter, More Comfortable Safety Footwear

- What role does VR play in safety shoe distribution? Enhance Global Branding with Immersive Showrooms

- Why is regular footwear internal integrity inspection critical? Prevent Foot Ulcers with Proactive Quality Control

- How do safety shoes with high-performance slip-resistant outsoles prevent injuries? Enhance Grip in Adverse Weather

- What is the primary function of protective footwear in poultry biosecurity? Maximize Flock Health and Biosecurity