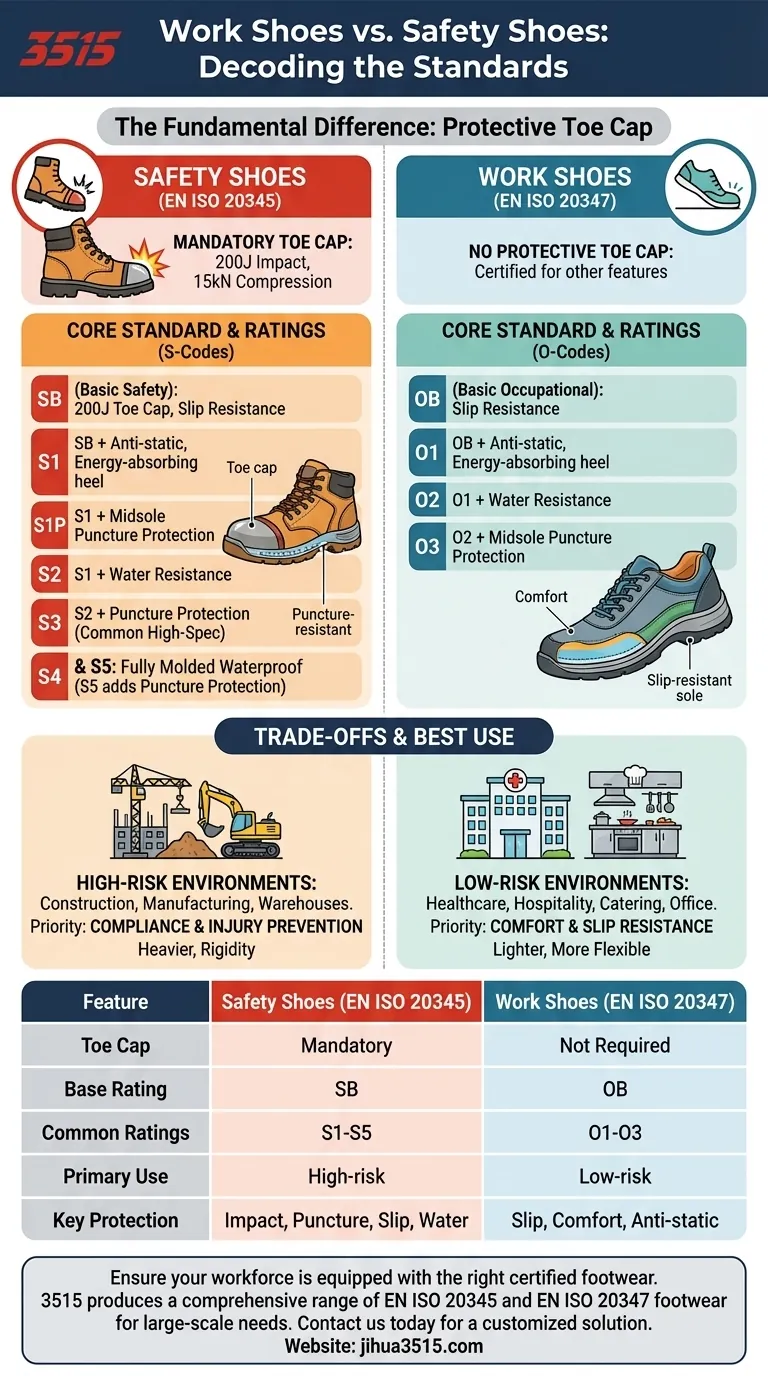

The fundamental difference between work shoes and safety shoes is the mandatory presence of a protective toe cap. Safety footwear, governed by the EN ISO 20345 standard, must include a toe cap tested to withstand significant impact and compression forces. In contrast, work footwear (often called occupational footwear) falls under the EN ISO 20347 standard and does not have this protective toe cap.

Your choice between these two categories is not a matter of preference but a direct function of your workplace risk assessment. Safety shoes are engineered for environments with impact and crushing hazards, while work shoes are designed for roles where other features like slip resistance and comfort take priority.

Decoding the Core Standards: Protection vs. Occupation

The international standards create a clear dividing line based on the presence of a single, critical safety feature. Understanding these two standards is the first step to ensuring proper foot protection.

EN ISO 20345: The Standard for Safety Footwear

This is the standard for what is formally known as safety footwear.

The non-negotiable requirement for this classification is a protective toe cap designed to shield the wearer from falling objects and compression. This toe cap must withstand an impact of 200 joules and a compression force of 15 kilonewtons.

Footwear meeting this standard is marked with an 'S', such as SB, S1, S1P, S2, S3, S4, or S5.

EN ISO 20347: The Standard for Occupational Footwear

This standard governs what is officially termed occupational footwear, often simply called work shoes.

These shoes are designed for professional use in environments where the specific risk of toe injury from impact or compression has been deemed negligible. They do not have a protective toe cap.

However, they can still offer other certified protective features like slip resistance, puncture resistance, and anti-static properties. They are marked with an 'O', such as OB, O1, O2, or O3.

A Practical Guide to Classification Codes

The letters and numbers on your footwear are not arbitrary; they represent a specific, tested level of protection.

Safety Shoe Ratings (S-Codes) Explained

All 'S' rated shoes begin with the SB (Safety Basic) requirements of a 200-joule toe cap and minimum slip resistance.

- S1: Provides SB protection plus anti-static properties and a fully enclosed, energy-absorbing heel.

- S1P: Includes all S1 features plus midsole protection against punctures.

- S2: Includes all S1 features plus resistance to water penetration and absorption.

- S3: The most common high-spec rating, combining all S2 features with puncture resistance (S2 + S1P).

- S4 & S5: These ratings apply to fully molded waterproof footwear, like rubber or polymer boots, with S5 including puncture resistance.

Work Shoe Ratings (O-Codes) Explained

All 'O' rated shoes begin with the OB basic requirements, which primarily certify slip resistance.

- O1: Provides OB protection plus anti-static properties and an enclosed, energy-absorbing heel.

- O2: Includes all O1 features plus resistance to water penetration and absorption.

- O3: Includes all O2 features plus midsole protection against punctures.

Understanding the Trade-offs

Choosing the right shoe involves balancing mandatory safety requirements with practical considerations like comfort and weight. This is not about choosing the "best" shoe, but the appropriate one.

The Inherent Weight of Protection

The primary trade-off of a safety shoe is its weight and rigidity. A steel or composite toe cap inherently adds weight and can reduce the overall flexibility of the shoe compared to a soft-toe work shoe.

When a Work Shoe is Sufficient

For many professions, the risk of a heavy object falling on the foot is virtually zero. In roles within healthcare, hospitality, catering, or certain office environments, an 'O' rated work shoe is ideal. It provides certified slip resistance and all-day comfort without the unnecessary weight of a toe cap.

When a Safety Shoe is Non-Negotiable

If your workplace risk assessment identifies any potential for impact or compression injuries, a safety shoe is mandatory. This includes construction sites, warehouses, manufacturing facilities, and any environment where heavy materials or machinery are present. In these cases, comfort is secondary to compliance and injury prevention.

Making the Right Choice for Your Goal

Your decision must be driven by a clear understanding of your environment's specific hazards.

- If your primary focus is compliance in a high-risk environment (construction, manufacturing): You must select a safety shoe (EN ISO 20345), ensuring the specific rating (e.g., S3) covers all potential hazards like punctures and water.

- If your primary focus is comfort and slip resistance for long shifts with no impact risk (healthcare, food service): A work shoe (EN ISO 20347) is the correct choice, providing certified performance without unnecessary weight.

- If your environment has mixed, lower-level risks (e.g., puncture hazards but no heavy objects): You can choose a high-rated work shoe like an O3 or a basic safety shoe like an S1P, depending on the outcome of your risk assessment.

Ultimately, understanding these standards empowers you to select footwear based on certified protection, not just features.

Summary Table:

| Feature | Safety Shoes (EN ISO 20345) | Work Shoes (EN ISO 20347) |

|---|---|---|

| Toe Cap | Mandatory (200J impact, 15kN compression) | Not Required |

| Base Rating | SB (Basic Safety) | OB (Basic Occupational) |

| Common Ratings | S1, S1P, S2, S3, S4, S5 | O1, O2, O3 |

| Primary Use | High-risk environments (construction, manufacturing) | Low-risk environments (healthcare, hospitality) |

| Key Protection | Impact, compression, puncture, water resistance | Slip resistance, comfort, anti-static properties |

Ensure your workforce is equipped with the right certified footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 safety shoes and EN ISO 20347 work shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and occupational footwear, ensuring compliance, comfort, and durability. Contact us today for a customized solution that meets your specific safety standards and volume needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What is the role of social media platforms as integration tools in the marketing of industrial and safety footwear?

- What are safety shoes also known as? A Guide to Protective Footwear Terms

- How do industrial-grade safety shoes reduce RSI risks? Prevent Lost Workdays with Biomechanical Support

- What are the main materials used in composite toe safety shoes? A Guide to Lightweight, Non-Metallic Protection

- What is the general recommendation for both steel and composite safety footwear after a significant impact? Replace Immediately for Safety.

- How does the anti-smashing feature of safety shoes protect technicians? Expert Guide to Ladder Setup Safety

- How do safety alerts influence footwear replacement in the ACA model? Prioritize Worker Safety with Rapid Risk Response

- Why are high-precision infrared motion capture systems used for gear? Proven Biomechanical Data for Protective Footwear