The unequivocal recommendation is that both steel and composite safety footwear must be replaced after any single significant impact. This is a non-negotiable safety rule because the protective components are designed to sacrifice their structural integrity to absorb the force of one major event, and their ability to protect you again is critically compromised.

After sustaining a significant impact, the structural integrity of a safety toe cap—whether steel or composite—is fundamentally compromised. Even without visible damage, its ability to protect you from a subsequent event is no longer guaranteed, making replacement a critical safety imperative.

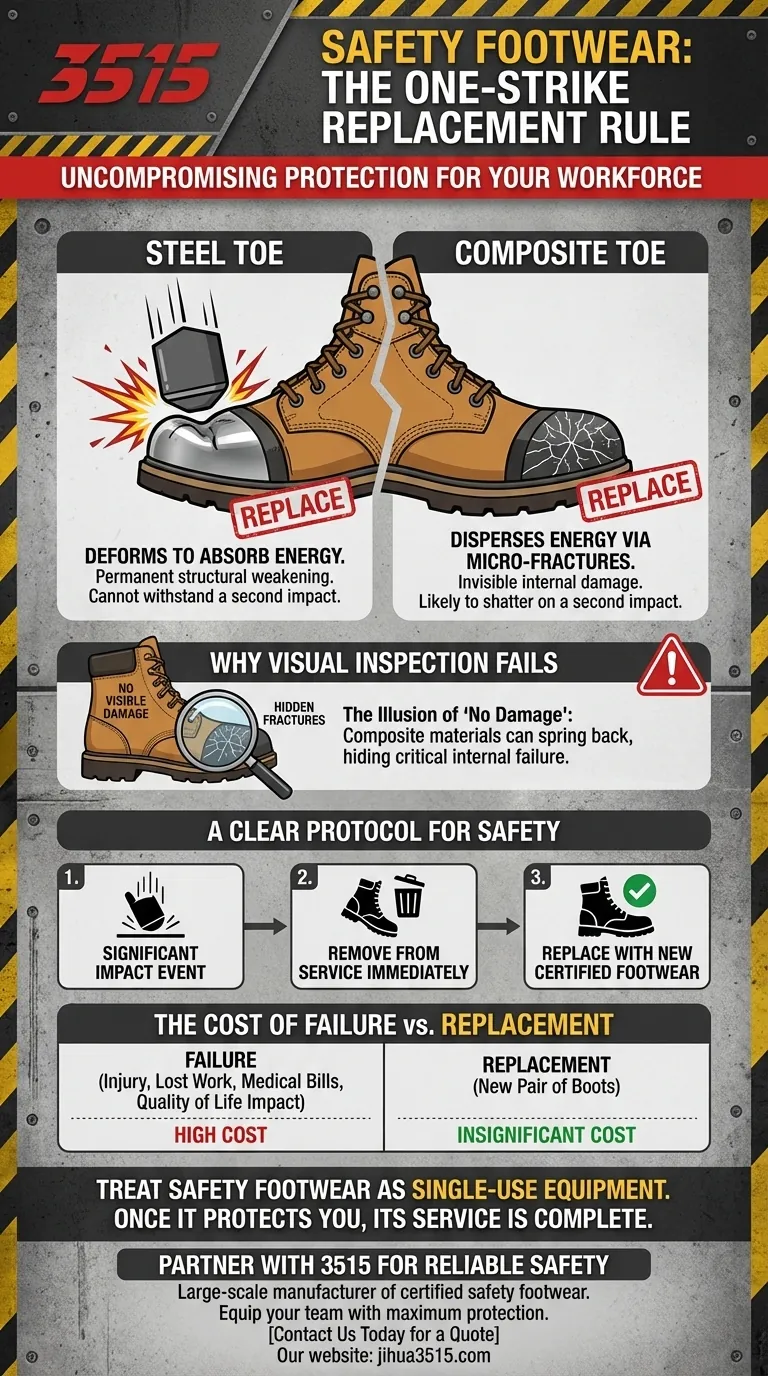

The Principle of One-Time Protection

Safety footwear operates on the same principle as a motorcycle helmet or a car's crumple zone. It is engineered to fail in a specific, controlled way to absorb and deflect energy that would otherwise cause a catastrophic injury.

How Steel Toes Absorb Impact

A steel toe cap protects by being incredibly strong and resistant to impact.

When it takes a severe hit, the steel may dent or deform. This deformation absorbs the energy, but it also permanently weakens the metal's structure at that point, making it unable to withstand a similar blow in the future.

The Hidden Risk in Composite Toes

Composite materials (like carbon fiber, fiberglass, or plastic) protect by dispersing energy across the entire structure.

An impact that might not even leave a mark on the surface can create thousands of invisible micro-fractures within the material's matrix. While the toe cap may look perfectly intact, it has lost its internal strength and will likely shatter on a second impact.

Why Visual Inspection Is Not Enough

The most dangerous assumption you can make is that if a boot looks okay, it is okay. The damage that negates the boot's protective capability is often impossible to see.

What Constitutes a "Significant Impact"?

There is no universal force measurement, so a simple, safe rule is crucial.

A significant impact is any event where a heavy object falls onto the foot, causing a sharp, noticeable blow. If the event would have likely caused a serious injury without the safety toe, consider the footwear's protective capability to be consumed.

The Illusion of "No Damage"

After an incident, a composite toe may spring back to its original shape, showing no outward signs of damage.

This is deceptive. The internal structure has been fractured and compromised. Relying on this footwear for future protection creates a severe and unnecessary risk.

The Cost of Failure vs. The Cost of Replacement

A foot injury can be debilitating, leading to lost work, high medical bills, and a permanent change in quality of life.

The cost of a new pair of certified safety boots is insignificant when weighed against the potential cost of a second incident where the footwear fails to perform.

A Clear Protocol for Your Safety

Your decision should not be based on visual inspection or the perceived severity of an impact. It must be based on a clear, risk-averse policy.

- If your primary focus is personal safety: Immediately remove the footwear from service after any significant impact and replace it. Your ability to walk away from one incident is proof the boots did their job; do not ask them to do it again.

- If your primary focus is managing workplace safety: Implement a strict, non-negotiable "one-strike" replacement policy for any safety footwear involved in an impact incident. This removes all guesswork and ensures every worker remains protected.

Treat your safety footwear as a critical piece of single-use safety equipment: once it has done its job of protecting you, its service is complete.

Summary Table:

| Safety Toe Type | How It Protects | Why It Must Be Replaced After Impact |

|---|---|---|

| Steel Toe | Deforms to absorb energy. | Permanent structural weakening; cannot withstand a second impact. |

| Composite Toe | Disperses energy via micro-fractures. | Invisible internal damage; likely to shatter on a second impact. |

Protect your workforce with uncompromising safety standards. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Ensure your team is equipped with reliable, high-performance boots designed for maximum protection. Contact us today to discuss your safety footwear needs and request a quote.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What is the importance of slip-resistant outsole technology in high-performance safety footwear? Protect Your Workforce

- Is ANSI Z41 still valid for safety footwear? No, It's Replaced by ASTM F2413

- Why wear standardized industrial safety shoes in ergonomic kinetic testing? Essential Variable Control

- How do I determine the right security guard safety boot sizes? A Guide to Perfect Fit & Protection

- What additional protection levels were introduced beyond the standard S1-S3 ratings? S4 to S7 Explained

- Why are industrial CAD/CAM systems essential for safety shoe production? Transform Your Footwear Manufacturing Today

- What are the responsibilities of employers regarding safety footwear under OSHA? Ensure Full Compliance & Protect Your Team

- Do electricians need to wear composite toe shoes? The Truth About EH-Rated Footwear