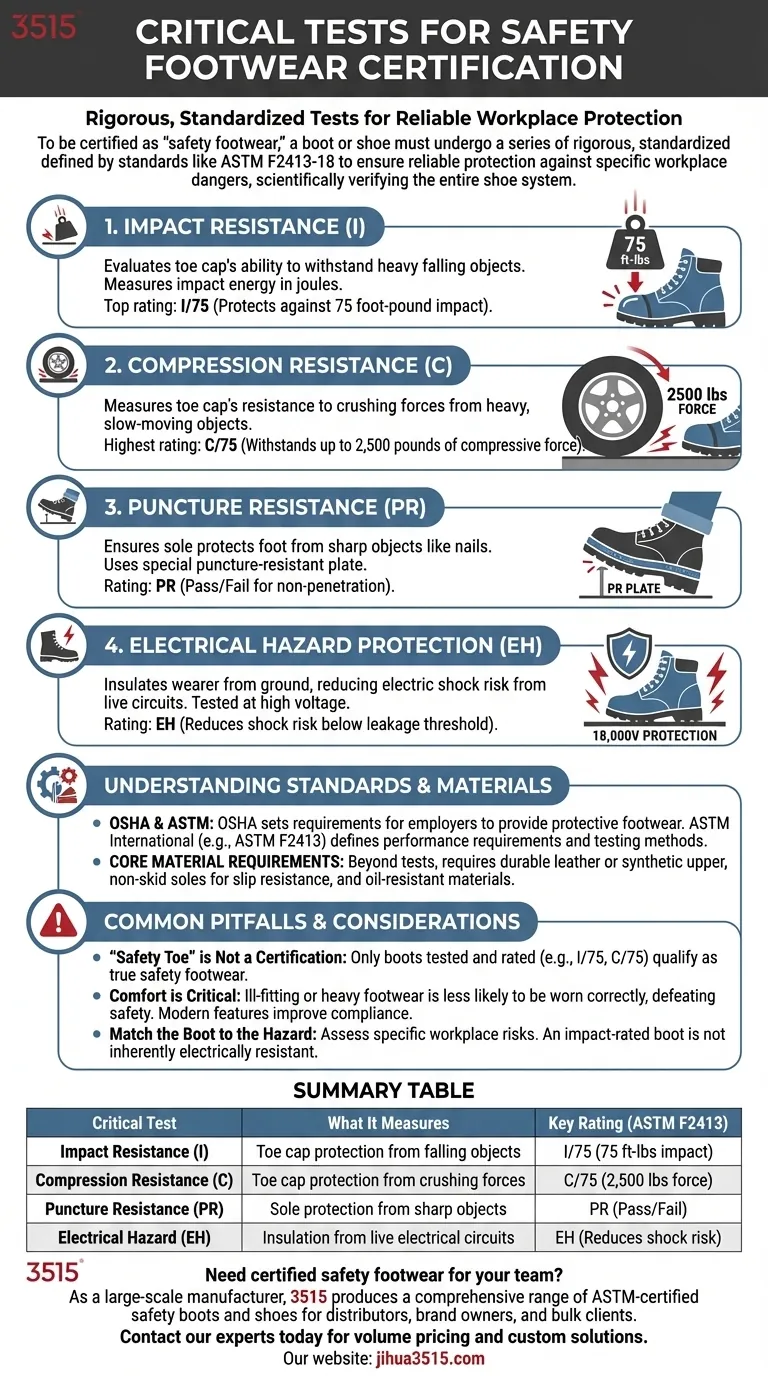

To be certified as "safety footwear," a boot or shoe must undergo a series of rigorous, standardized tests. The most critical evaluations focus on impact and compression resistance for the toe, puncture resistance for the sole, and protection against electrical hazards. These tests are not arbitrary; they are defined by standards like ASTM F2413-18 to ensure footwear provides reliable protection against specific workplace dangers.

The core principle of safety footwear testing is not just about having a "steel toe." It's about scientifically verifying that the entire shoe system can protect the wearer from a precise set of industrial hazards, from falling objects to live electrical circuits.

The Anatomy of a Safety Test: Core Protective Ratings

True safety footwear is defined by its performance in standardized tests. These evaluations are designed to simulate worst-case scenarios in a controlled environment, ensuring the footwear will perform when it matters most. The results of these tests are what earn a boot its specific safety ratings.

Impact Resistance (I)

This is the most recognized test for safety footwear. It evaluates the protective toe cap's ability to withstand a heavy object falling onto it. The test involves dropping a specified weight from a set height to generate a specific impact energy, measured in joules.

Under the common ASTM standard, the top rating is I/75, which means the toe cap can protect the wearer's foot from a 75 foot-pound impact.

Compression Resistance (C)

This test measures the toe cap's ability to resist crushing forces from a heavy, slow-moving object, like a rolling vehicle wheel or a piece of equipment. The footwear is subjected to a heavy, rolling load to see if the toe cap deforms.

The highest rating is C/75, indicating the footwear can withstand up to 2,500 pounds of compressive force before the toe cap unacceptably encroaches on the foot space.

Puncture Resistance (PR)

This test focuses on the sole of the footwear. It ensures the sole can protect the foot from sharp objects on the ground, such as nails, screws, or metal shards. A special puncture-resistant plate, often made of steel or a composite material, is built into the sole.

During the test, a sharp steel pin is forced into the sole under high pressure to verify that it cannot penetrate the protective layer.

Electrical Hazard Protection (EH)

For workers who may come into contact with live electrical circuits, EH-rated footwear is essential. This test measures the sole's ability to insulate the wearer from the ground, significantly reducing the risk of electric shock.

The footwear is subjected to a high voltage (e.g., 18,000 volts at 60 Hz for one minute) to ensure leakage current remains below a very low threshold.

Understanding the Standards and Materials

The tests themselves are only one part of the equation. They are governed by strict standards and rely on specific material properties to be effective.

The Role of OSHA and ASTM

OSHA (Occupational Safety and Health Administration) sets the requirement that employers must provide protective footwear in hazardous environments.

ASTM International (specifically standard ASTM F2413) defines the performance requirements and the testing methods. Essentially, OSHA says "you must wear safe shoes," and ASTM defines what "safe" means and how to prove it.

Core Material Requirements

Beyond passing the performance tests, standards also mandate certain material qualities. Certified footwear typically requires a durable leather or synthetic upper, non-skid soles for slip resistance, and oil-resistant materials to prevent degradation in industrial environments.

Common Pitfalls and Considerations

Choosing the right footwear requires looking beyond a single feature. A misunderstanding of the ratings or a failure to consider the work environment can lead to inadequate protection.

"Safety Toe" is Not a Certification

A boot can have a steel or composite toe without being officially certified. If it has not been tested and rated according to ASTM standards (e.g., I/75, C/75), it does not qualify as true safety footwear and offers no guaranteed level of protection.

Comfort is a Critical Safety Factor

A test can't measure long-term comfort, but it's vital for safety. Footwear that is ill-fitting or excessively heavy is less likely to be worn correctly or consistently, defeating its purpose. Modern safety shoes use features like padded collars, supportive insoles, and lightweight composite materials to improve compliance.

Matching the Boot to the Hazard

Not all safety shoes are created equal. A boot rated for impact and compression is useless against electrical hazards if it isn't also EH-rated. A comprehensive hazard assessment of the workplace is the only way to determine the specific combination of protections needed.

Making the Right Choice for Your Goal

Base your selection on a clear understanding of the specific risks present in your work environment.

- If your primary focus is protection from falling objects: Look for footwear with an I/75 and C/75 rating clearly marked.

- If your primary focus is working around construction debris or sharp scrap: Puncture Resistance (PR) rated soles are non-negotiable.

- If your primary focus is working near live electrical equipment: Ensure the footwear is explicitly EH rated to provide insulation.

- If your primary focus is working on slippery or oily surfaces: Prioritize boots with certified slip-resistant and oil-resistant soles.

Ultimately, selecting the correct safety footwear is an exercise in matching the certified protection directly to the specific hazard you face.

Summary Table:

| Critical Test | What It Measures | Key Rating (ASTM F2413) |

|---|---|---|

| Impact Resistance (I) | Toe cap protection from falling objects | I/75 (75 ft-lbs impact) |

| Compression Resistance (C) | Toe cap protection from crushing forces | C/75 (2,500 lbs force) |

| Puncture Resistance (PR) | Sole protection from sharp objects | PR (Pass/Fail) |

| Electrical Hazard (EH) | Insulation from live electrical circuits | EH (Reduces shock risk) |

Need certified safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring your workforce has the right protection matched to their specific hazards.

Contact our experts today for volume pricing and custom solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards