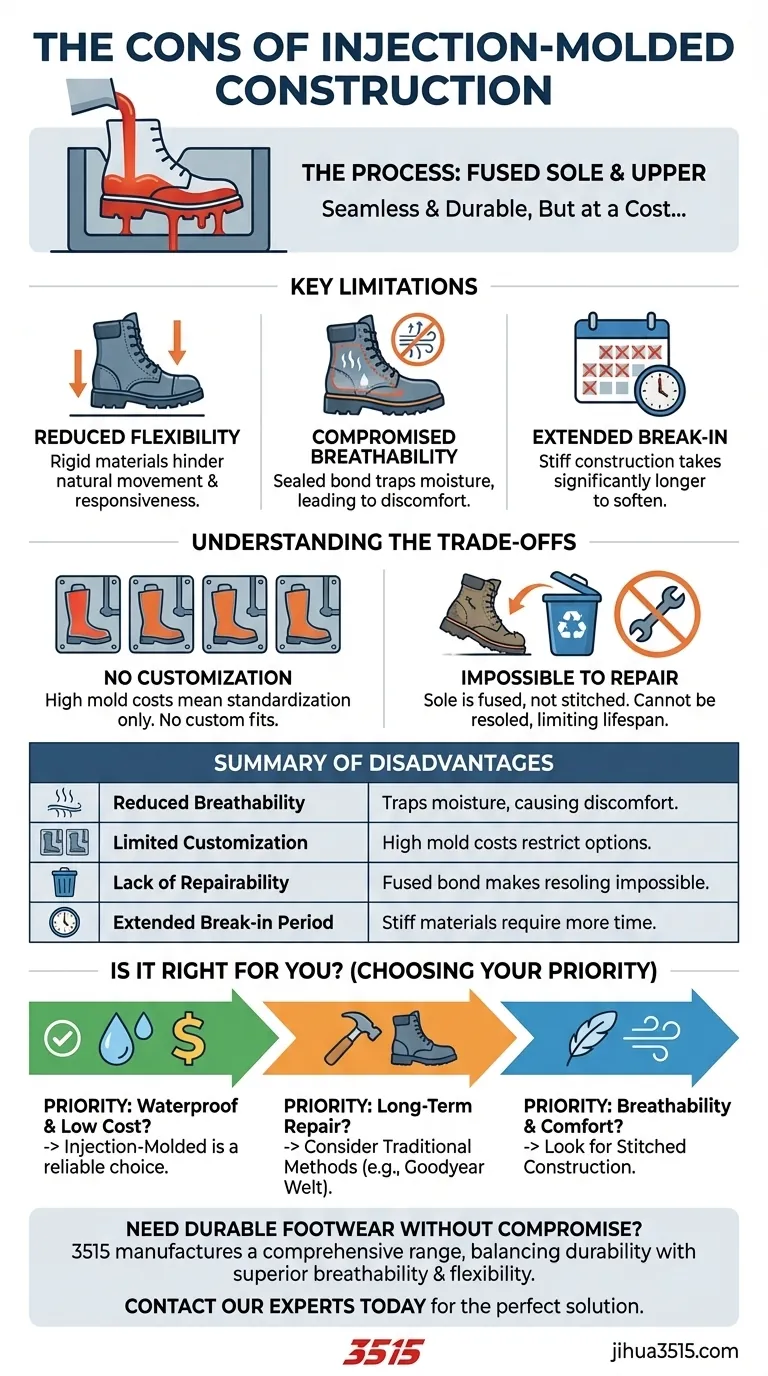

The primary disadvantages of injection-molded construction are its limited customization, reduced breathability, and lack of reparability. This manufacturing method also creates a more rigid product that can be less flexible and require a longer break-in period compared to traditional alternatives.

While injection molding produces a highly durable and often waterproof product at a lower cost, this efficiency comes at the direct expense of breathability, long-term serviceability, and a personalized fit.

The Principle Behind the Process

What is Injection Molding?

Injection molding in footwear or other gear involves placing the upper part of the product into a mold. Molten material, typically a polymer like polyurethane (PU) or PVC, is then injected into the mold.

This material forms the sole and fuses directly to the upper, creating a seamless, single-unit bond. Understanding this process is key to understanding its inherent limitations.

Key Limitations Explained

Reduced Flexibility and Movement

The materials used for the sole in injection molding are chosen for extreme durability and abrasion resistance. This often results in a very stiff construction.

This rigidity can hinder the natural flexing motion of your foot, feeling less responsive and more restrictive, especially during the initial weeks of use.

Compromised Breathability

The direct fusion of the sole to the upper creates a completely sealed, waterproof bond. While excellent for keeping water out, it also prevents moisture from escaping.

This lack of breathability can lead to a hot, sweaty internal environment, causing discomfort and potential issues like blisters, particularly in warmer conditions or during high-exertion activities.

Extended Break-in Period

The combination of stiff sole materials and a less forgiving construction means injection-molded products typically have a longer and more uncomfortable break-in period.

Unlike leather or stitched constructions that gradually conform to your foot's shape, the molded sole resists this process, requiring more time to soften and feel comfortable.

Understanding the Trade-offs: Durability vs. Serviceability

The Challenge of Customization

The high cost of creating precision molds makes injection molding a process geared toward mass production and standardization.

Offering custom fit options is economically unfeasible, as it would require a unique and expensive mold for every variation. Therefore, you are limited to the standard sizes and shapes offered by the manufacturer.

The Problem with Repairs

This is arguably the most significant long-term disadvantage. The sole is not stitched or glued on; it is fused into a single piece with the upper.

This permanent bond makes it nearly impossible to resole or repair the product. Once the sole wears out, the entire item must typically be discarded, limiting its total lifespan and creating more waste.

Is Injection-Molded Construction Right for You?

Choosing a product with injection-molded construction depends entirely on your priorities and intended use.

- If your primary focus is maximum water resistance and upfront durability at a lower cost: This construction method is an excellent and highly reliable choice.

- If your primary focus is long-term value and reparability: You should consider traditional methods like a Goodyear welt, which are specifically designed to be resoled.

- If your primary focus is breathability and immediate comfort: Look for products with stitched construction and materials that allow for better moisture transfer.

Ultimately, understanding these trade-offs empowers you to select the right tool for your specific job.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Reduced Breathability | Sealed construction traps moisture, causing discomfort. |

| Limited Customization | High mold costs restrict fit and style options. |

| Lack of Repairability | Fused sole/upper bond makes resoling impossible. |

| Extended Break-in Period | Stiff materials require more time to become comfortable. |

Need durable footwear that doesn't compromise on comfort or customization?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including advanced constructions that balance durability with superior breathability and flexibility.

Contact our experts today to discuss how we can manufacture the perfect footwear solution for your market needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job