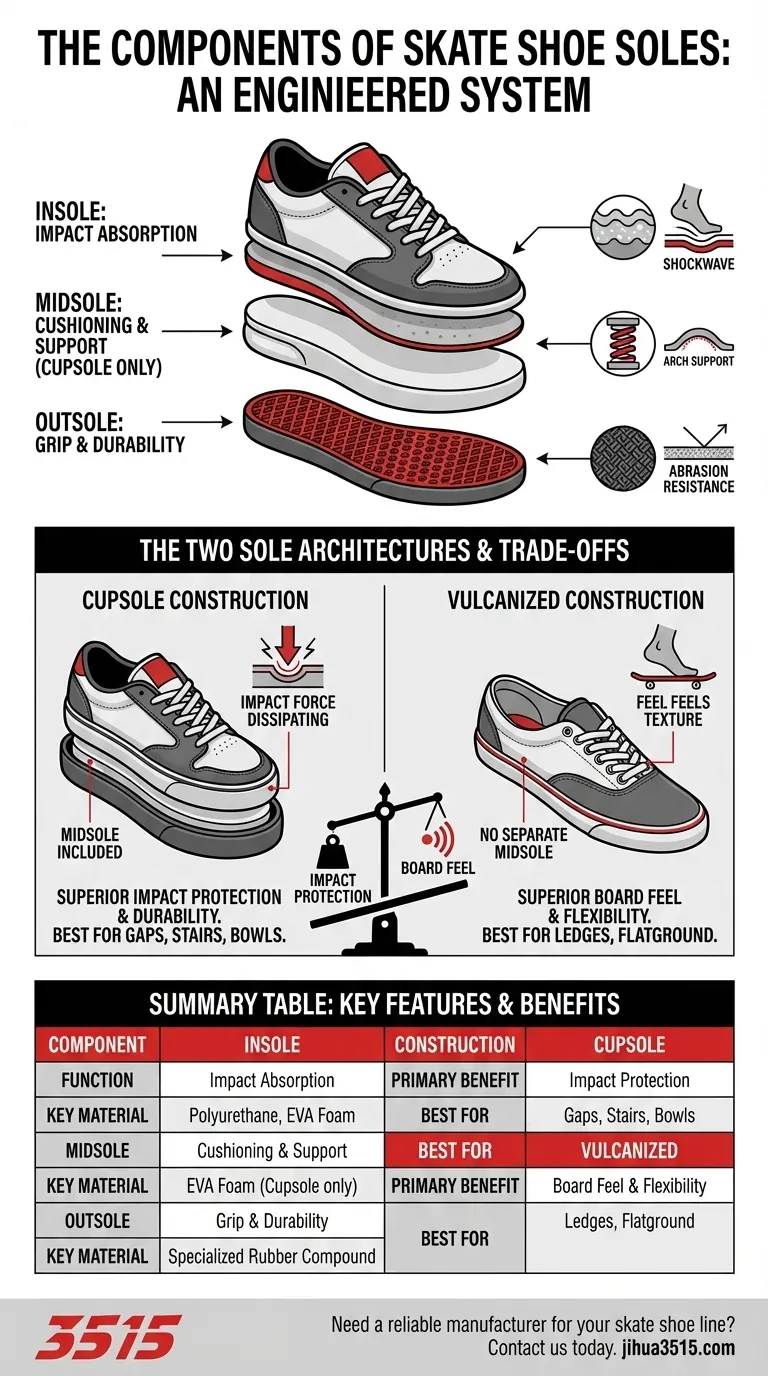

At its core, a skate shoe sole is an engineered system with three primary components: an insole for impact protection, a midsole for cushioning, and an outsole for grip and durability. However, the presence and construction of these components vary significantly depending on the sole's primary design architecture.

The anatomy of a skate shoe sole represents a fundamental trade-off in performance. Every design is a calculated balance between protecting your feet from impact and allowing you to feel and control the board beneath them.

Deconstructing the Skate Shoe Sole

To understand how a skate shoe performs, you must first understand the function of each layer. These components work together to manage the unique forces of skateboarding.

The Insole: Your First Line of Defense

The insole is the removable footbed inside the shoe. Its primary job is impact absorption.

Modern skate insoles are often made from advanced polyurethane or EVA foams designed to dissipate the energy from landing on concrete, reducing heel bruises and joint stress.

The Midsole: The Core of Cushioning

The midsole is a layer of shock-absorbing material, typically EVA foam, that sits between the insole and the outsole.

Crucially, a distinct midsole is only found in cupsole constructions. It provides the bulk of the shoe's cushioning and structural support.

The Outsole: The Point of Contact

The outsole is the durable rubber layer that makes contact with the griptape and the ground. Its design is critical for both grip and durability.

Skate outsoles use specific rubber compounds and tread patterns designed to lock into griptape for control while resisting the intense abrasion that quickly destroys a standard sneaker.

The Two Sole Architectures: Cupsole vs. Vulcanized

The single most important factor determining a skate shoe's performance is its construction method. This is where the components are assembled into one of two primary types.

Cupsole Construction

A cupsole is named for its construction: the outsole is a single, pre-molded rubber piece that "cups" the upper part of the shoe and is then stitched or glued on.

This method allows for the inclusion of a thick, supportive midsole, making cupsoles superior for impact protection and durability. They are the preferred choice for skating large gaps, stairs, and anything involving high impact.

Vulcanized Construction

Vulcanized shoes are built differently. The shoe's outsole is attached to the upper using a flexible rubber foxing tape, and the entire assembly is then heat-treated (baked) in a special oven.

This process bonds all the parts into one cohesive unit. By eliminating a separate, chunky midsole, vulcanized soles offer significantly more flexibility and board feel right out of the box.

Understanding the Trade-offs

Choosing a skate shoe is about understanding which compromises you are willing to make. No single shoe can maximize every performance attribute.

Board Feel vs. Impact Protection

This is the classic trade-off. Vulcanized shoes excel at board feel because the thin, flexible sole transmits more sensory information from the board to your feet.

Conversely, cupsoles excel at impact protection due to their dedicated midsole, which absorbs far more shock. This protection comes at the cost of feeling the board's subtle contours.

Why Other Shoe Soles Fail

The specific needs of skateboarding highlight why other athletic shoes are unsuitable.

Walking shoe soles are too soft and lack the durability to withstand griptape. Safety shoe soles are far too rigid and heavy, completely eliminating the board feel necessary for control.

Making the Right Choice for Your Skating Style

Your decision should be based entirely on your primary needs as a skateboarder.

- If your primary focus is technical ledge or flatground skating: A vulcanized sole will provide the superior board feel and flexibility needed for precise control.

- If your primary focus is skating gaps, stairs, or bowls: A cupsole will deliver the critical impact protection and support required to protect your feet and joints.

- If you want a versatile, all-around shoe: Look for a modern, slimmed-down cupsole, which often provides a good balance between cushioning and board feel.

Understanding your sole's construction empowers you to choose the right tool for your style of skateboarding.

Summary Table:

| Component | Function | Key Material |

|---|---|---|

| Insole | Impact Absorption | Polyurethane, EVA Foam |

| Midsole | Cushioning & Support | EVA Foam (Cupsole only) |

| Outsole | Grip & Durability | Specialized Rubber Compound |

| Construction | Primary Benefit | Best For |

| Cupsole | Impact Protection | Gaps, Stairs, Bowls |

| Vulcanized | Board Feel & Flexibility | Ledges, Flatground |

Need a reliable manufacturer for your skate shoe line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including high-performance skate shoes with both cupsole and vulcanized constructions. We can help you develop the perfect sole for your target market.

Contact us today to discuss your production needs and get a quote!

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What materials are best for athletic activities in warm climates? Stay Cool with Moisture-Wicking Fabrics

- What is a Flyknit shoe? The Ultimate Guide to Seamless, Lightweight Performance

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team

- What are the features of cross training shoes? Master Versatile Performance for Your Workouts

- What is high-tech 'air' mesh, and how is it used in footwear? The Key to Cool, Lightweight Shoes