The defining characteristics of footwear textiles are a combination of five key factors: the fiber used, the thread weight (denier), the weave or knit pattern, any backing material applied, and special surface treatments. These elements work together to determine a fabric's durability, weight, appearance, and suitability for a specific shoe design, from internal linings to the external upper.

Choosing the right textile is not about finding a single "best" material. It's about strategically selecting a specific combination of fiber, construction, and finishing to meet the precise functional and manufacturing demands of the footwear.

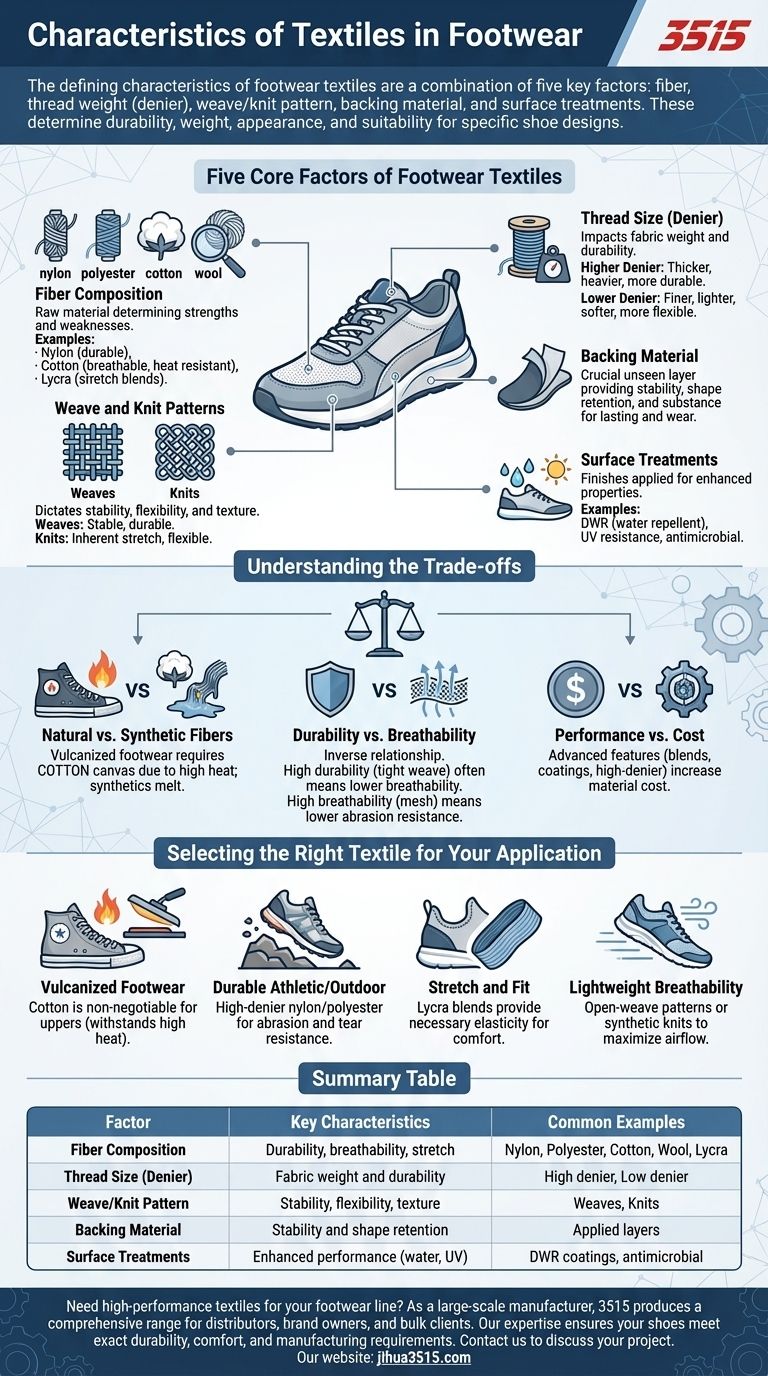

The Five Core Factors of Footwear Textiles

To properly evaluate a textile, you must look beyond its surface appearance and analyze the components that dictate its performance. These five factors are the fundamental building blocks of any fabric used in a shoe.

Fiber Composition

This is the raw material from which the threads are made. Each fiber type offers a distinct profile of strengths and weaknesses.

Common fibers include nylon and polyester, valued for their high durability and versatility. Cotton is a natural fiber prized for its breathability and heat resistance, while wool offers insulation. Lycra is almost never used alone but is blended with other fibers to provide critical stretch.

Thread Size (Denier)

Denier is the unit of measurement for the weight and thickness of a thread. This directly impacts the fabric's durability and feel.

A higher denier number indicates a thicker, heavier, and typically more durable thread, suitable for high-wear areas. A lower denier signifies a finer, lighter thread, resulting in a softer and more flexible fabric.

Weave and Knit Patterns

This describes how the threads are interlaced to form the fabric. The construction method dictates the textile's stability, flexibility, and texture.

Weaves involve interlacing threads at right angles, creating a stable and often durable structure. Knits are made from interlocking loops of yarn, which gives the fabric inherent stretch and flexibility.

Backing Material

Many footwear textiles have a backing applied to them. This unseen layer is critical for performance and manufacturing.

Backings provide stability, prevent the fabric from stretching out of shape, and add substance. They are essential for ensuring the textile can withstand the stresses of lasting and everyday wear.

Surface Treatments

These are finishes applied to the fabric after it has been constructed to enhance its properties.

Common treatments include durable water repellent (DWR) coatings for weather resistance, UV-resistant finishes to prevent color fading, and antimicrobial treatments for odor control in shoe linings.

Understanding the Trade-offs

Selecting a textile is always a process of balancing competing priorities. An advantage in one area often requires a compromise in another.

Natural vs. Synthetic Fibers

The choice between natural and synthetic fibers is often dictated by the shoe's construction method.

The most critical example is in vulcanized footwear. The high heat used in the vulcanization process to cure the rubber sole will melt synthetic fibers like nylon or polyester. For this reason, cotton canvas is the essential choice for the uppers of these shoes.

Durability vs. Breathability

There is often an inverse relationship between a fabric's toughness and its ability to breathe.

A high-denier nylon with a very tight weave will be exceptionally resistant to abrasion but may trap heat and moisture. Conversely, an open-knit mesh offers maximum airflow but is more susceptible to snagging and tearing.

Performance vs. Cost

Advanced features and high-performance fibers come at a price.

A standard polyester fabric is a cost-effective workhorse. However, adding a specialty blend with Lycra, applying a waterproof coating, and using a high-denier thread will all increase the final cost of the material.

Selecting the Right Textile for Your Application

The ideal choice depends entirely on the shoe's intended purpose and manufacturing process. Use these guidelines to inform your decision.

- If your primary focus is vulcanized footwear (e.g., canvas sneakers): Cotton is non-negotiable for the upper material due to its ability to withstand the high-heat curing process.

- If your primary focus is durable athletic or outdoor shoes: High-denier nylon or polyester offers the best resistance to abrasion and tearing.

- If your primary focus is stretch and fit (e.g., collars, linings): Textiles blended with Lycra provide the necessary elasticity for comfort and a snug fit.

- If your primary focus is lightweight breathability: Look for open-weave patterns or knits made from synthetic fibers like polyester to maximize airflow.

By mastering these material characteristics, you can make intentional design choices that perfectly align with your footwear's intended performance.

Summary Table:

| Factor | Key Characteristics | Common Examples |

|---|---|---|

| Fiber Composition | Determines durability, breathability, stretch | Nylon, Polyester, Cotton, Wool, Lycra blends |

| Thread Size (Denier) | Impacts fabric weight and durability | High denier (durable), Low denier (soft/flexible) |

| Weave/Knit Pattern | Affects stability, flexibility, and texture | Weaves (stable), Knits (stretchy) |

| Backing Material | Adds stability and shape retention | Applied layers for lasting and wear resistance |

| Surface Treatments | Enhances performance (water resistance, UV protection) | DWR coatings, antimicrobial finishes |

Need high-performance textiles for your footwear line? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in textile selection ensures your shoes meet exact durability, comfort, and manufacturing requirements. Contact us today to discuss your project and leverage our full production capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- What closure methods are used in winter cycling shoes? Find the Right Seal for Cold Weather Riding

- What role do automated sorting and logistics centers play? Boost Efficiency and Manage Volatile Footwear Demand

- What role do smart sensors and RFID readers play in the footwear data chain? Driving Precision in Shoe R&D

- What are the specific requirements for footwear intended to be used with smart vibratory insole systems?

- How do winter boots compare in warmth to regular shoes with overshoes? The Ultimate Guide to Cold-Weather Footwear

- What is the importance of high-quality website visual design? Boost Trust & Sales for Safety and Outdoor Footwear

- Why is cross-industry collaborative infrastructure necessary for PU footwear? Unlock Scalable Circular Manufacturing

- How do quality shoes reflect personal elegance? Showcase Your Personal Standards from the Ground Up