At its core, vulcanization is a chemical process that fundamentally changes the properties of rubber, making it an ideal material for footwear soles. The primary benefits of a vulcanized sole are its exceptional flexibility, its superior grip on smooth surfaces, and the direct, sensitive "board feel" it provides, making it a staple in skate and casual footwear.

The decision to choose a vulcanized sole is not about finding a universally "better" shoe, but about understanding a fundamental trade-off: you are prioritizing flexibility and ground-feel over structured cushioning and impact absorption.

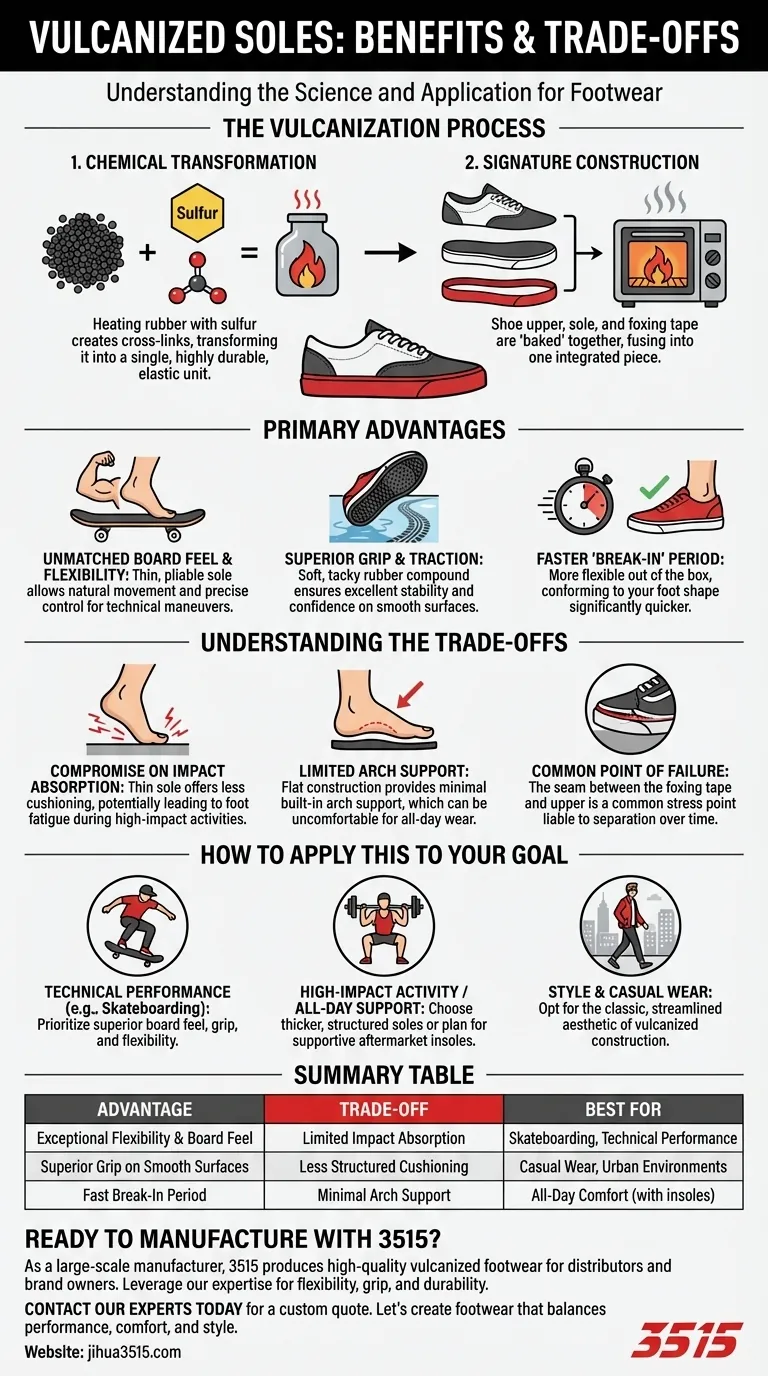

The Vulcanization Process Explained

To understand the benefits and drawbacks, you must first understand the construction. Vulcanization is not just a type of sole, but a complete method of shoemaking.

The Chemical Transformation

The process involves heating rubber with sulfur. This creates cross-links between the rubber polymers, transforming the soft, pliable material into a single, highly durable, and elastic unit. This treated rubber is wear-resistant, less prone to cracking, and maintains its flexibility over time.

The Signature Construction

During assembly, the shoe's upper is bonded to the rubber sole using a strip of rubber tape called foxing. The entire shoe is then heated in a large oven, or autoclave. This "bakes" the components together, fusing the upper, sole, and foxing tape into one integrated piece, which is what gives vulcanized shoes their distinct, flat-soled appearance.

The Primary Advantages of Vulcanized Soles

The unique construction method directly leads to the most celebrated characteristics of these shoes.

Unmatched Board Feel and Flexibility

Because the sole is thin and has been baked to be exceptionally pliable, it allows for natural foot movement. For activities like skateboarding, this provides an unparalleled feel for the board, enabling precise control for technical maneuvers.

Superior Grip and Traction

The vulcanization process results in a soft, tacky rubber compound. This gives the sole an excellent grip on smooth surfaces like a skateboard deck, boat deck, or city pavement, increasing stability and confidence.

A Faster "Break-In" Period

Compared to shoes with stiffer, molded soles, vulcanized shoes are far more flexible right out of the box. This means they conform to the shape of your foot much more quickly, requiring a significantly shorter and more comfortable break-in period.

Understanding the Trade-offs

The very features that make vulcanized soles great for board feel also create their primary limitations.

The Compromise on Impact Absorption

The thinness of the sole means there is less material to cushion your foot from hard impacts. For high-impact activities, this can lead to foot fatigue and potential heel bruising without the addition of a high-quality insole.

Limited Arch Support

Vulcanized construction results in an almost perfectly flat sole. This provides minimal to no built-in arch support, which can be uncomfortable for individuals who require it for all-day wear.

A Common Point of Failure

While the rubber sole itself is quite durable, the seam where the foxing tape meets the shoe's upper is a common stress point. Over time, repeated flexing can cause this seam to separate, which is often the first part of the shoe to fail.

How to Apply This to Your Goal

Your choice should be dictated entirely by your primary use case.

- If your primary focus is technical performance (like skateboarding): The superior board feel, grip, and flexibility of a vulcanized sole are almost essential for control.

- If your primary focus is high-impact activity or all-day support: A shoe with a thicker, more structured sole may be a better choice, or plan to use a supportive aftermarket insole.

- If your primary focus is style and casual wear: Vulcanized construction offers a classic, streamlined aesthetic that is highly versatile for urban environments.

Ultimately, understanding the core trade-off between feel and support empowers you to select the right footwear for your specific needs.

Summary Table:

| Advantage | Trade-off | Best For |

|---|---|---|

| Exceptional Flexibility & Board Feel | Limited Impact Absorption | Skateboarding, Technical Performance |

| Superior Grip on Smooth Surfaces | Less Structured Cushioning | Casual Wear, Urban Environments |

| Fast Break-In Period | Minimal Arch Support | All-Day Comfort (with insoles) |

Ready to manufacture the perfect vulcanized sole footwear for your market?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality vulcanized shoes and boots for distributors, brand owners, and bulk clients. We leverage deep expertise in the vulcanization process to deliver the flexibility, grip, and durability your customers demand.

Contact our experts today to discuss your specific needs and get a custom quote. Let us help you create footwear that perfectly balances performance, comfort, and style.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

People Also Ask

- What role do slip-resistant rubber materials play in safety shoes? Ensuring Grip and Stability in Hazardous Workplaces

- Why is rubber commonly used for non-slip soles? The Science of Superior Grip

- What are the advantages of rubber soles in safety boots? Unbeatable Grip & Durability

- What should be avoided when storing boots with outsoles? Protect Your Investment from Dry Rot & Decay

- Why are rubber soles beneficial in cold-weather boots? Superior Traction & Waterproofing