In short, Nitrile outsoles offer a crucial trifecta of protection that goes far beyond simple chemical resistance. They provide exceptional tolerance to high temperatures up to 300°C, superior slip resistance that exceeds certification standards, and a durable stability that is essential for hazardous work environments.

While the boot's upper material handles chemical splashes, the Nitrile outsole ensures the worker remains stable, safe from extreme temperatures, and protected from slips and falls, addressing multiple hazards simultaneously.

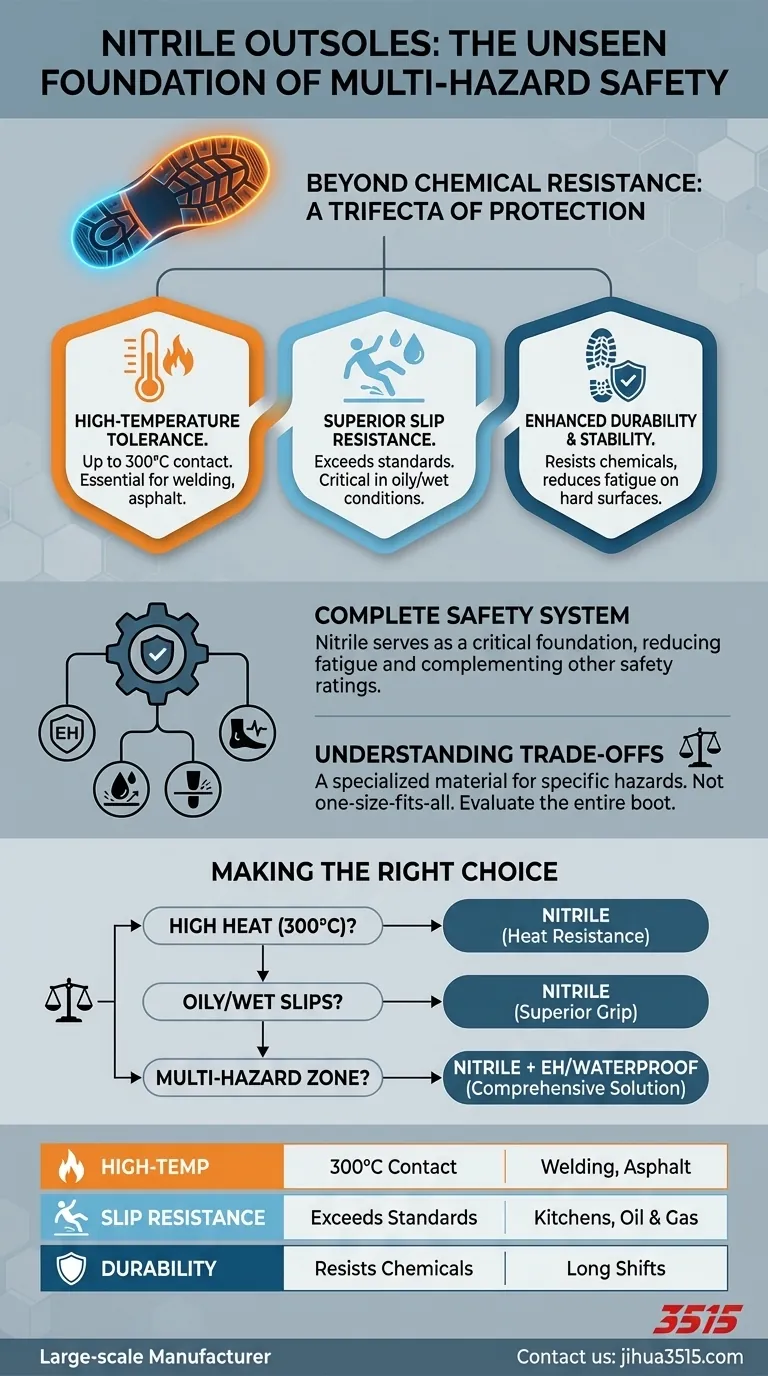

Beyond Chemical Splash: The Core Attributes of Nitrile

The term "Chemical Resistant" often focuses on the boot's upper materials. However, the outsole is the foundation of your safety, and Nitrile provides a high-performance base with distinct advantages.

High-Temperature Tolerance

A key differentiator for Nitrile is its ability to withstand contact with surfaces up to 300°C. This makes it an essential feature in environments like manufacturing, welding, or asphalt work where incidental contact with extreme heat is a daily risk.

Superior Slip Resistance

Nitrile outsoles are engineered to exceed standard slip resistance certifications. Their performance is particularly notable in oily or wet conditions, directly preventing the common trips and slips that cause a majority of workplace injuries.

Enhanced Durability and Stability

Nitrile is a robust rubber compound that resists degradation from chemicals and oils. This durability provides a stable, reliable platform for the foot, which helps reduce worker fatigue over long shifts on hard surfaces.

How Nitrile Fits into a Complete Safety System

A high-quality safety boot is an integrated system, not just a collection of parts. A Nitrile outsole serves as the critical foundation for other protective features.

The Base for Multi-Hazard Protection

The stability and resilience of a Nitrile outsole complement other safety ratings. It provides the trustworthy footing needed for boots that also offer Electrical Hazard (EH) protection, waterproofing, or Penetration Resistance.

Reducing Overall Worker Fatigue

A stable and comfortable footbed is proven to reduce fatigue. The reliable grip and solid foundation of a Nitrile outsole mean the worker expends less energy staying balanced, leading to greater comfort and focus throughout the day.

Understanding the Trade-offs

While highly effective, it's important to view Nitrile as a specialized material designed to solve specific problems. No single material is perfect for every application.

Focus on Environmental Need

The primary benefits of Nitrile—heat and advanced slip resistance—are most valuable in environments where those specific hazards exist. For a simple, dry work area, its advantages may not be as critical as other factors like boot weight or flexibility.

Evaluating the Entire Boot

The outsole is only one component. The chemical resistance of the boot's upper, the integrity of its seams, and its overall fit are just as important. A Nitrile outsole cannot compensate for a poorly constructed boot.

Making the Right Choice for Your Environment

To select the appropriate footwear, match the boot's features to your primary operational hazards.

- If your primary focus is high-heat environments: Nitrile's 300°C heat resistance is a non-negotiable feature for worker safety.

- If your primary focus is preventing slips in oily or wet conditions: Nitrile's superior grip provides a critical layer of defense against common accidents.

- If your primary focus is all-around protection in a multi-hazard zone: Seek a boot that combines a Nitrile outsole with other ratings like EH or waterproofing to create a comprehensive safety solution.

Ultimately, choosing a boot with a Nitrile outsole is an investment in proactive safety that addresses critical hazards well beyond the chemical label.

Summary Table:

| Key Benefit | Key Feature | Ideal For |

|---|---|---|

| High-Temperature Tolerance | Withstands contact up to 300°C | Welding, manufacturing, asphalt work |

| Superior Slip Resistance | Exceeds certification standards in oily/wet conditions | Kitchens, factories, oil & gas |

| Durability & Stability | Resists degradation from oils/chemicals, reduces fatigue | Long shifts on hard surfaces |

Need high-performance safety boots with Nitrile outsoles for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including models with the advanced Nitrile outsoles detailed in this article. We can provide the durable, multi-hazard protection your workforce needs.

Contact us today for expert guidance and to discuss your specific requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards