The primary advantage of oil-resistant safety boots is their ability to maintain both traction and structural integrity in environments contaminated with oils, fuels, and other hydrocarbons. This specialized design directly prevents slips and falls on slick surfaces while also ensuring the boot itself doesn't degrade, providing a reliable foundation for worker safety.

The core function of an oil-resistant boot is not just about grip; it’s about predictable performance. Where standard footwear soles can swell, harden, or break down upon contact with oil, these boots are engineered to remain stable, ensuring both safety and a longer service life.

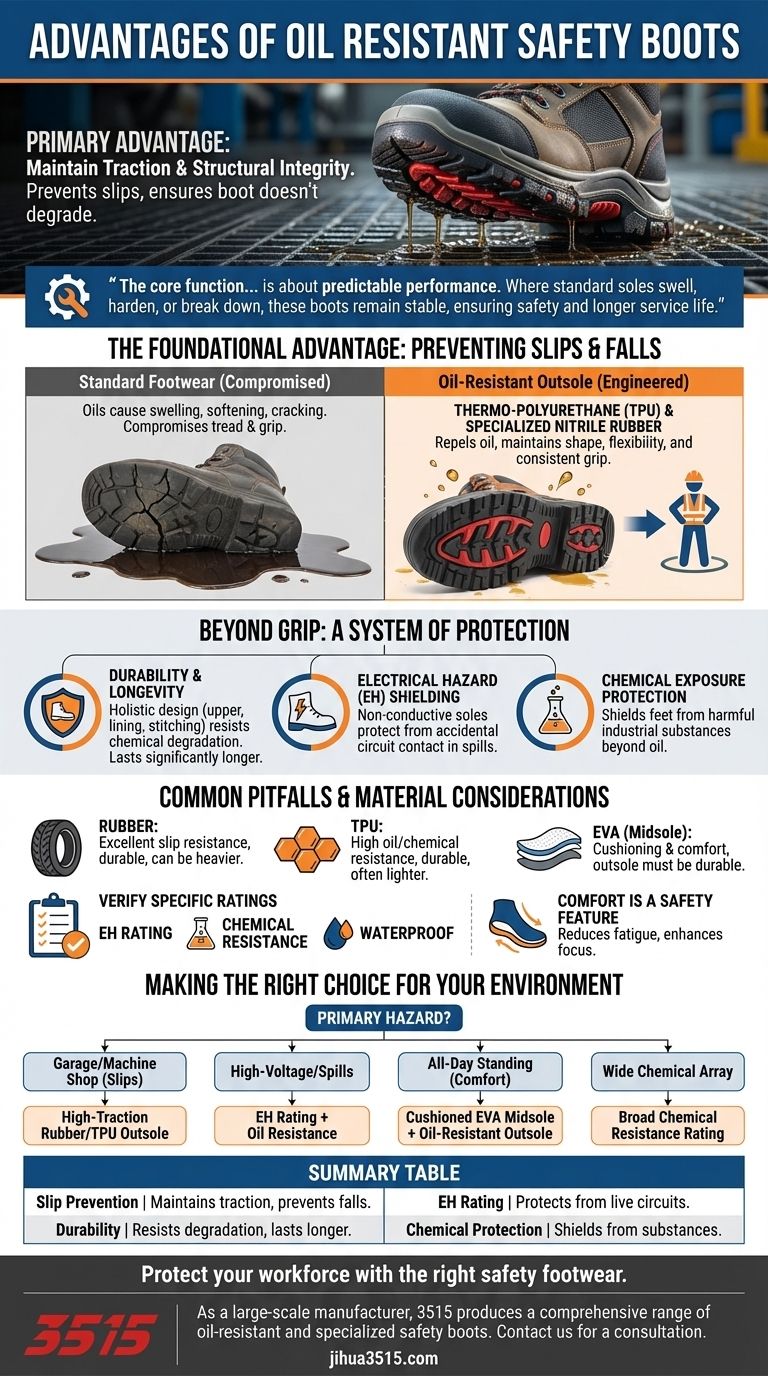

The Foundational Advantage: Preventing Slips and Falls

The most immediate and critical benefit of oil-resistant boots is mitigating the risk of slips, trips, and falls, which are among the most common workplace accidents.

How Oil Compromises Standard Footwear

Oils and hydrocarbon-based fluids are aggressive solvents. They can cause the materials in a standard boot sole to swell, become overly soft, or harden and crack over time.

This chemical reaction severely compromises the sole's tread and its ability to grip a surface, turning a manageable environment into a high-risk one.

The Engineering of an Oil-Resistant Outsole

Oil-resistant outsoles are made from specific compounds designed to repel oil rather than absorb it. Materials like thermo-polyurethane (TPU) and specialized nitrile rubber are formulated to maintain their shape, flexibility, and grip even after prolonged exposure.

This ensures the boot's traction remains consistent and reliable, giving the wearer stable footing on contaminated floors.

Beyond Grip: A System of Protection

While slip prevention is the primary driver, these boots are part of a larger safety system, often incorporating multiple protective features essential for hazardous environments.

Durability and Longevity

An oil-resistant design applies to more than just the sole. The upper materials, linings, and even the stitching are often selected to resist degradation from chemical exposure.

This holistic approach means the boot lasts significantly longer in harsh conditions, providing a better return on investment and reducing the frequency of replacement.

Shielding from Electrical Hazards

Many oil-resistant boots also carry an Electrical Hazard (EH) rating. This is a critical feature in industrial settings where spilled fluids can create a conductive path.

EH-rated boots are designed with non-conductive soles and heels to protect the wearer from accidental contact with live electrical circuits.

Protection Against Chemical Exposure

The same properties that make a boot resistant to oil often provide a degree of protection against other common industrial chemicals. This shields the wearer's feet from direct contact with potentially harmful substances.

Common Pitfalls and Material Considerations

Choosing the right boot requires understanding that not all "oil-resistant" labels signify the same level of protection.

Sole Material Determines Performance

The choice of sole material involves trade-offs.

- Rubber: Offers excellent slip resistance and durability but can be heavier.

- TPU: Provides high resistance to oil and chemicals and is very durable, often lighter than rubber.

- EVA (Ethylene-vinyl acetate): Often used in the midsole for cushioning and comfort, but the outsole must still be a durable, resistant material like rubber or TPU.

Verify Specific Safety Ratings

"Oil-resistant" is a baseline feature. Always check for additional certifications specific to your job's risks. Look for explicit EH ratings, chemical resistance specifications, or waterproof membranes if those hazards are present.

Comfort is a Safety Feature

A boot that causes fatigue or discomfort is a distraction and a safety risk. Modern designs incorporate ergonomic footbeds and cushioning to reduce fatigue for workers who stand for long periods, enhancing both comfort and focus.

Making the Right Choice for Your Environment

Your final decision should be guided by a clear assessment of your primary workplace hazards.

- If your primary focus is preventing slips in a garage or machine shop: Prioritize a boot with a high-traction, oil-resistant rubber or TPU outsole.

- If you work with high-voltage equipment and frequent fluid spills: An Electrical Hazard (EH) rating is non-negotiable in addition to oil resistance.

- If your concern is all-day standing comfort with moderate oil exposure: Look for a boot combining a cushioned EVA midsole with a durable, oil-resistant outsole.

- If you face a wide array of chemicals beyond oil: You must select a boot specifically rated for broad chemical resistance, as standard oil resistance may not be sufficient.

Investing in the correct, purpose-built safety boot is a critical foundation for workplace safety and performance.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Slip Prevention | Maintains traction on oily surfaces, preventing falls. |

| Durability | Resists degradation from oils and chemicals, lasting longer. |

| Electrical Hazard (EH) Rating | Protects against accidental contact with live circuits. |

| Chemical Protection | Shields feet from a range of industrial substances. |

Protect your workforce with the right safety footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of oil-resistant and specialized safety boots for distributors, brand owners, and bulk clients. Our production capabilities ensure durable, reliable footwear designed for your specific industrial hazards.

Contact us today for a consultation and discover how our boots can enhance your workplace safety and performance.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- What are the technical advantages of integrating sensors into safety shoes? Achieve Superior Motion Capture Precision

- Why is TPU selected for encapsulating ultrasonic modules in safety/outdoor footwear? Unrivaled Protection & Durability

- How do safety shoes and puncture-resistant boots protect against snakebites? Secure Your Field Workers with 3515 Gear

- What are the key properties of nylon as an upper material for labour protection shoes? A Guide to Lightweight Durability

- How does metatarsal protection in safety footwear work? The Essential Guide to Foot Safety

- Why is slip-resistance a critical feature for safety shoes used in insecticide spraying? Prevent Workplace Falls

- Is there a connection between toe material and electrical hazard ratings in boots? The Truth About Boot Safety

- Which type of safety-toe boot is better for cold weather? Focus on Insulation & Waterproofing