At its core, the primary advantage of a Goodyear welt is its fundamental design for longevity and repair. Unlike most mass-produced shoes with glued-on soles, this traditional construction method allows the sole to be replaced multiple times without compromising the shoe's upper, drastically extending its useful life while enhancing comfort and water resistance.

A Goodyear welt is less a feature and more a philosophy of footwear construction. It trades the low initial cost and disposability of mass-produced shoes for a significant upfront investment in a durable, repairable, and comfortable foundation that can last for decades.

The Anatomy of a Superior Shoe

To understand the value of a Goodyear welt, you must look beyond the price tag and examine the underlying architecture. This method directly addresses the most common failure points of modern footwear.

Unmatched Durability and Longevity

The defining characteristic is how the components are joined. A strip of leather, known as the welt, is stitched to the upper and the insole. The outsole is then stitched to this welt, creating an incredibly robust and secure bond.

This stitched construction avoids the delamination and sole separation common in cheaper, cemented shoes. With proper care of the leather upper, a Goodyear welted shoe can easily last 20 years or more.

The Power of Resoling

This construction method is engineered for repair. Because the outsole is stitched to the welt and not directly to the upper, a cobbler can easily remove the old sole and stitch on a new one.

This process can be repeated multiple times. It allows the high-quality leather upper to be preserved, developing a unique and desirable patina over years of wear, long after a mass-produced shoe would have been discarded.

A Foundation of Custom Comfort

The space between the insole and the outsole is filled with a layer of granulated cork. Initially firm, this cork layer gradually compresses and molds to the unique shape of your foot with every step.

Over time, this creates a personalized footbed that offers a level of custom support and comfort that a synthetic, mass-produced insole simply cannot replicate.

Superior Water Resistance

The welt acts as a physical barrier, creating a small wall around the edge of the shoe. This significantly minimizes water penetration between the sole and the upper, keeping your feet drier than in a typical cemented shoe.

Understanding the Investment and Trade-offs

While the advantages are significant, this construction method is not without its considerations. It represents a deliberate choice that prioritizes long-term performance over short-term convenience.

The Significant Upfront Cost

Goodyear welting is a labor-intensive process that requires skilled craftsmanship. This complexity is directly reflected in the price.

A pair can cost hundreds of dollars, with bespoke options running into the thousands. This initial investment is substantially higher than that for a mass-produced alternative.

The Required Break-in Period

The same components that provide lasting comfort—the leather insole and cork filling—make the shoe quite stiff when new. A break-in period is necessary for the materials to soften and conform to your foot.

This contrasts with many modern shoes that feel comfortable immediately but lack the same structural integrity and potential for long-term, molded comfort.

Making the Right Choice for Your Goal

The decision to invest in a Goodyear welted shoe depends entirely on your priorities.

- If your primary focus is long-term value and sustainability: The ability to resole the shoe makes it a more economical and environmentally sound choice over the course of its extended lifespan.

- If your primary focus is personalized comfort: The cork and leather footbed will mold precisely to your foot, offering a level of custom support that mass-produced shoes cannot match.

- If your primary focus is immediate affordability and convenience: A mass-produced shoe with a cemented sole is a better option for a lower initial cost and no required break-in period.

Ultimately, choosing a Goodyear welted shoe is an investment in a piece of footwear engineered to evolve with you for years to come.

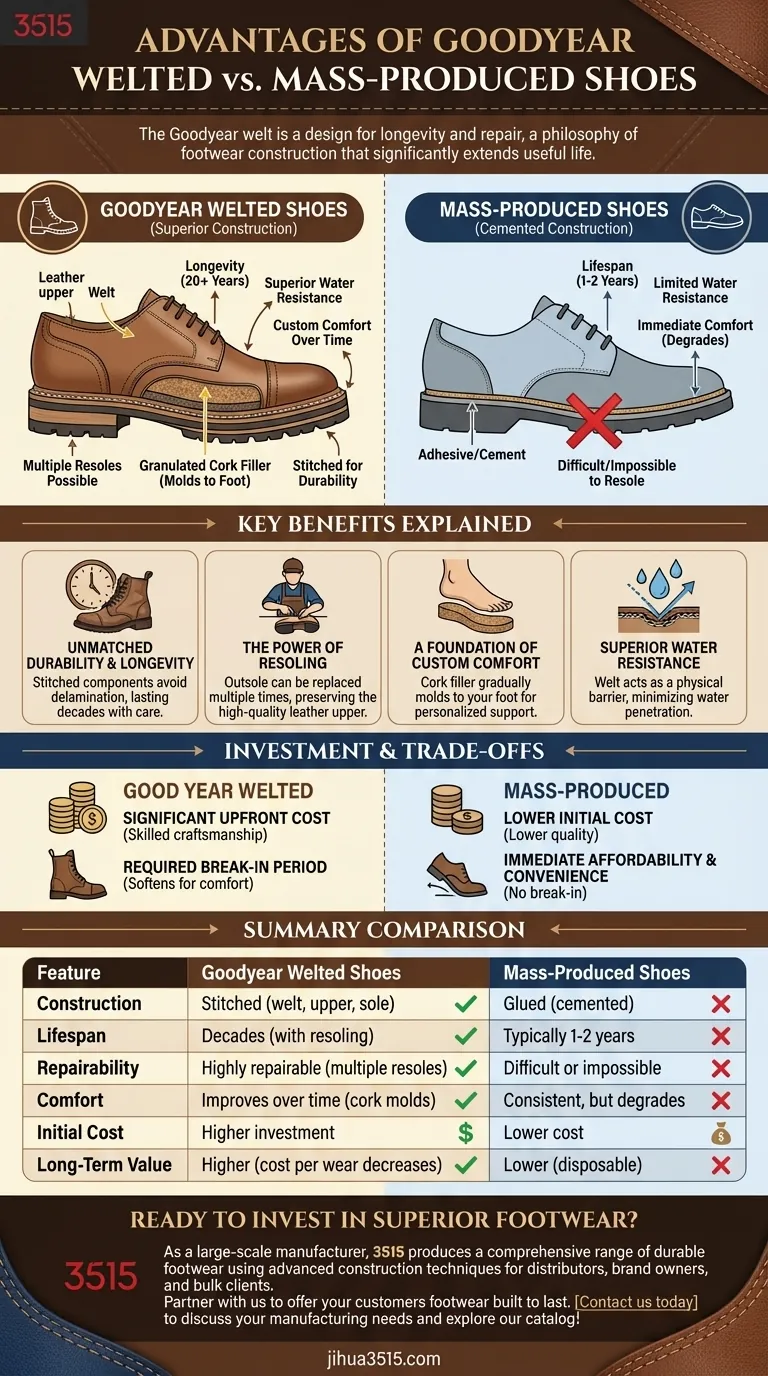

Summary Table:

| Feature | Goodyear Welted Shoes | Mass-Produced Shoes |

|---|---|---|

| Construction | Stitched (welt, upper, sole) | Glued (cemented) |

| Lifespan | Decades (with resoling) | Typically 1-2 years |

| Repairability | Highly repairable (multiple resoles) | Difficult or impossible to repair |

| Comfort | Improves over time (cork molds to foot) | Consistent, but may degrade |

| Initial Cost | Higher investment | Lower cost |

| Long-Term Value | Higher (cost per wear decreases) | Lower (disposable) |

Ready to Invest in Superior Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear using advanced construction techniques for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring quality and value.

Partner with us to offer your customers footwear built to last.

Contact us today to discuss your manufacturing needs and explore our catalog!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries