My task is clear: I need to act as the senior technical advisor here and create an authoritative, unbiased guide to help you decide if composite toe boots are the right choice for your needs.

I immediately need to answer "What are the advantages of composite toe boots?" But, more importantly, I need to explain why those advantages are relevant in the context of your specific work. My goal isn't just to list facts but to help you make an informed decision compared to steel or alloy toes.

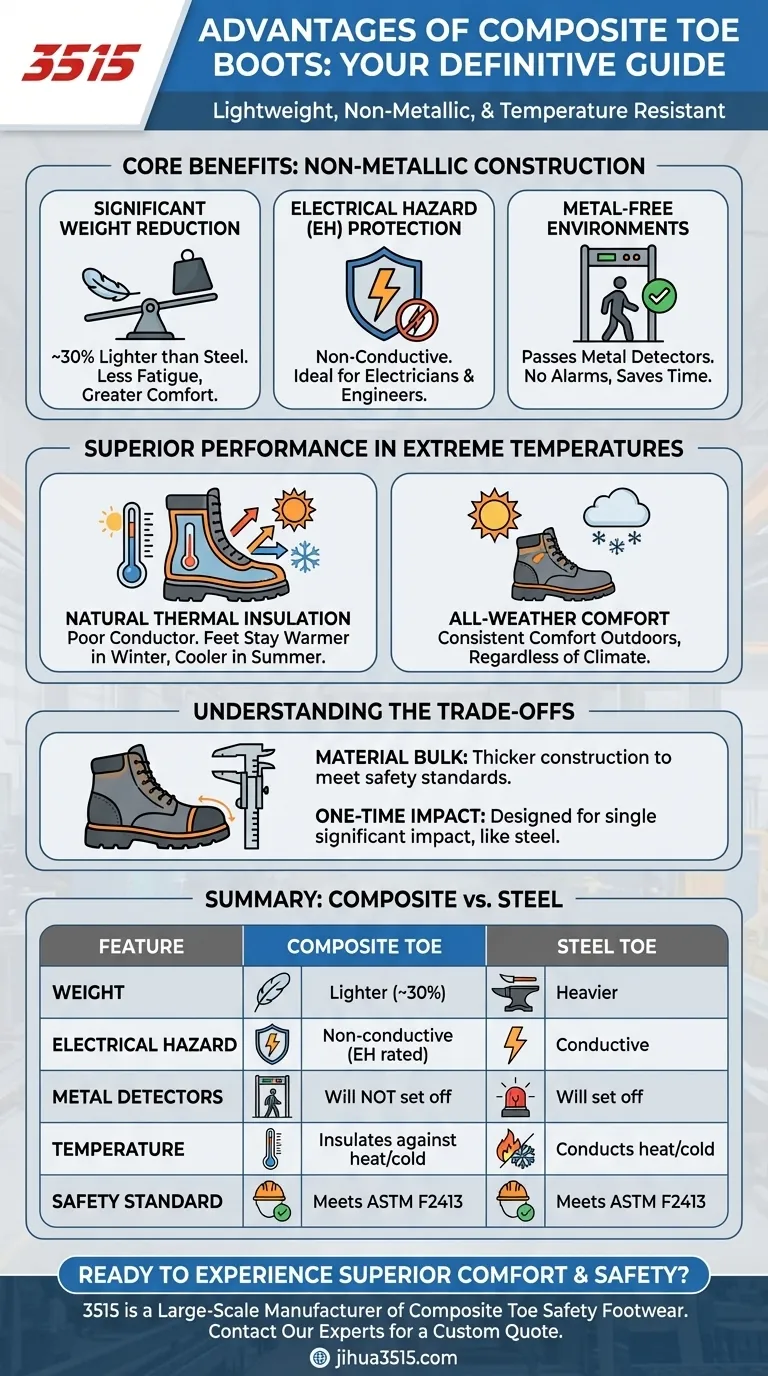

The Bottom Line: Composite toe boots offer distinct advantages: they are incredibly lightweight, non-metallic (no electricity conduction or triggering metal detectors), and temperature resistant. They excel where weight, electrical hazards, and thermal comfort are critical factors. Understanding the trade-offs of bulk and construction compared to traditional steel toes will help you determine the best option for your working needs.

The Core Benefits of Non-Metallic Construction

The non-metallic nature of composite toes is the root cause of many of their benefits.

Significant Weight Reduction

One of the most noticeable advantages is the significant weight reduction. Composite toes are noticeably lighter—about 30% lighter than steel toes. This lighter weight translates to less fatigue over a long work day, which is a major comfort factor.

Electrical Hazard (EH) Protection

Because they are non-conductive, composite toe boots provide excellent Electrical Hazard (EH) protection. This is crucial for electricians, engineers, and anyone working in environments with live electricity.

Metal-Free Environments

If you work in high-security areas or environments with metal detectors, composite toe boots are the perfect solution. You can walk through metal detectors without setting them off, which saves time and hassle.

Superior Performance in Extreme Temperatures

Another key advantage is their performance in extreme temperatures.

Natural Thermal Insulation

Unlike metal, composite materials do not conduct heat or cold as efficiently. This means they act as a natural insulator.

Comfort in Hot and Cold Climates

The thermal insulation provided by composite toes means more comfort when working outdoors in extreme heat or cold. Your feet will stay warmer in the winter and cooler in the summer.

Understanding the Trade-offs

Objectivity demands I mention the trade-offs. The reference material emphasizes the advantages, but I know from my experience that composite toes, while lighter, must be made thicker than steel toes to meet safety standards.

The key trade-off for their lighter weight can be perceived bulkiness. Keep in mind that while composite toes may be thicker, this is a construction trade off to meet and maintain the same standards of protection as steel. While the information emphasizes meeting the standard, there is no need to make unsupported claims about single, extreme impacts.

Safety Standards Are Not Compromised

Despite being non-metallic, it's crucial to understand that composite toe boots are certified to the same ASTM impact and compression standards as steel toes. This should put any safety concerns to rest.

Meeting ASTM Requirements

Composite toe boots offer the same level of impact and compression protection, though achieving that level requires a different construction method. This is a crucial assurance for users.

Making the Right Choice for Your Work Environment

Consider the specific demands of your job and environment:

- Reduce daily fatigue or walk long distances: The lightweight nature of composite toes will be an advantage.

- Work with live electricity or in high-security areas: The non-metallic, non-conductive properties are paramount.

- Work outdoors in extreme heat or cold: The thermal insulation of composite toes will make a difference.

Ultimately, choosing the right safety footwear is about matching the right features to your unique needs. With these insights, you can confidently choose the best option for your safety and comfort. The primary advantages of composite toe boots are that they are significantly lighter than steel toe boots, do not conduct electricity, and provide superior thermal insulation against heat and cold. Because they are made from non-metallic materials like Kevlar, carbon fiber, or specialized plastics, they also won't set off metal detectors.

The central takeaway is that composite toe boots offer safety protection equivalent to steel toes under ASTM standards, but with distinct advantages in environments where weight, temperature extremes, or electrical hazards are the primary daily concerns.

The Core Benefits of Non-Metallic Construction

The defining feature of a composite toe cap is its lack of metal. This fundamental difference is the source of its most significant advantages over traditional steel toes.

Significant Weight Reduction

Composite toe boots are approximately 30% lighter than their steel toe counterparts. While this may seem minor, the reduced weight translates directly to less foot fatigue over the course of a long workday, especially for those who are constantly on their feet or walk long distances.

Electrical Hazard (EH) Protection

Because they contain no metal, composite materials do not conduct electricity. This makes them the ideal choice for electricians, engineers, and anyone working in environments where accidental contact with live electrical circuits is a risk.

Compatibility with Metal-Free Environments

The non-metallic construction allows workers to pass through metal detectors without triggering an alarm. This is a crucial advantage in high-security settings, such as airports, government buildings, or sensitive industrial sites, saving time and hassle.

Superior Performance in Extreme Temperatures

Metal is a highly effective conductor of temperature, a property that is undesirable in a safety boot. Composite materials solve this problem.

Natural Thermal Insulation

Composite materials are poor conductors of temperature, meaning they provide natural insulation. They do not transfer cold or heat from the environment to your feet as readily as a steel cap does.

All-Weather Comfort

This thermal resistance makes composite toe boots far more comfortable for outdoor workers. In cold weather, they help keep feet warmer, and in hot weather, they don't heat up, ensuring consistent comfort regardless of the ambient temperature.

Understanding the Trade-offs

While the advantages are clear, it's important to understand the complete picture. Objectivity requires acknowledging the inherent characteristics of the material.

Material Bulk

To achieve the same ASTM safety rating for impact and compression resistance as steel, a composite toe cap must be slightly bulkier. The materials are not as dense as steel, so more of it is required to provide the same level of protection. This can result in a slightly larger-looking toe box.

One-Time Impact Resistance

All certified safety toes—steel or composite—are designed to protect you from a single, significant impact event. After such an event, the boot's integrity is compromised and it must be replaced. It is a misconception that one material is universally "stronger" than the other in the field; both must meet the exact same ASTM F2413 safety standard to be sold as protective footwear.

Making the Right Choice for Your Work Environment

Selecting the right boot is about matching its features to the specific demands of your job.

- If your primary focus is reducing daily fatigue: The significant weight savings of composite toe boots will provide the most noticeable benefit.

- If your primary focus is electrical safety or working in secure areas: The non-metallic, non-conductive properties of composite toes are non-negotiable.

- If your primary focus is comfort in outdoor or temperature-variable work: The superior thermal insulation of composite toe boots is the clear choice.

Ultimately, understanding these core advantages empowers you to select the protective footwear that best serves your specific safety needs and daily comfort.

Summary Table:

| Feature | Composite Toe Boots | Steel Toe Boots |

|---|---|---|

| Weight | Significantly lighter (~30% less) | Heavier |

| Electrical Hazard | Non-conductive (EH rated) | Conductive |

| Metal Detectors | Will not set off alarms | Will set off alarms |

| Temperature | Insulates against heat/cold | Conducts heat/cold |

| Safety Standard | Meets ASTM F2413 impact/compression | Meets ASTM F2413 impact/compression |

Ready to experience the superior comfort and safety of composite toe boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of composite toe safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots designed for maximum comfort and protection.

Let us help you equip your team with the right safety solution. Contact our experts today for a custom quote and discover how 3515 can be your trusted manufacturing partner.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the benefits of heavy duty work boots? Invest in Superior Safety & Durability

- Why are professional safety shoes required during heavy-duty girder erection? Essential Protection for Infrastructure

- Why are industrial safety boots with steel toes necessary for machine operators? Essential Foot Protection for Safety