At their core, structural fire boots are specialized personal protective equipment (PPE) designed for the unique and hazardous conditions of fighting fires within buildings. They are engineered to provide comprehensive protection with features like reinforced safety toes, puncture-resistant soles, slip-resistant outsoles, and complete waterproofing for operations in and around structures.

Structural fire boots are not simply heavy-duty footwear; they are an engineered safety system. Their design prioritizes protecting a firefighter's feet from the specific combination of impact, puncture, water, and extreme heat found in structural emergencies.

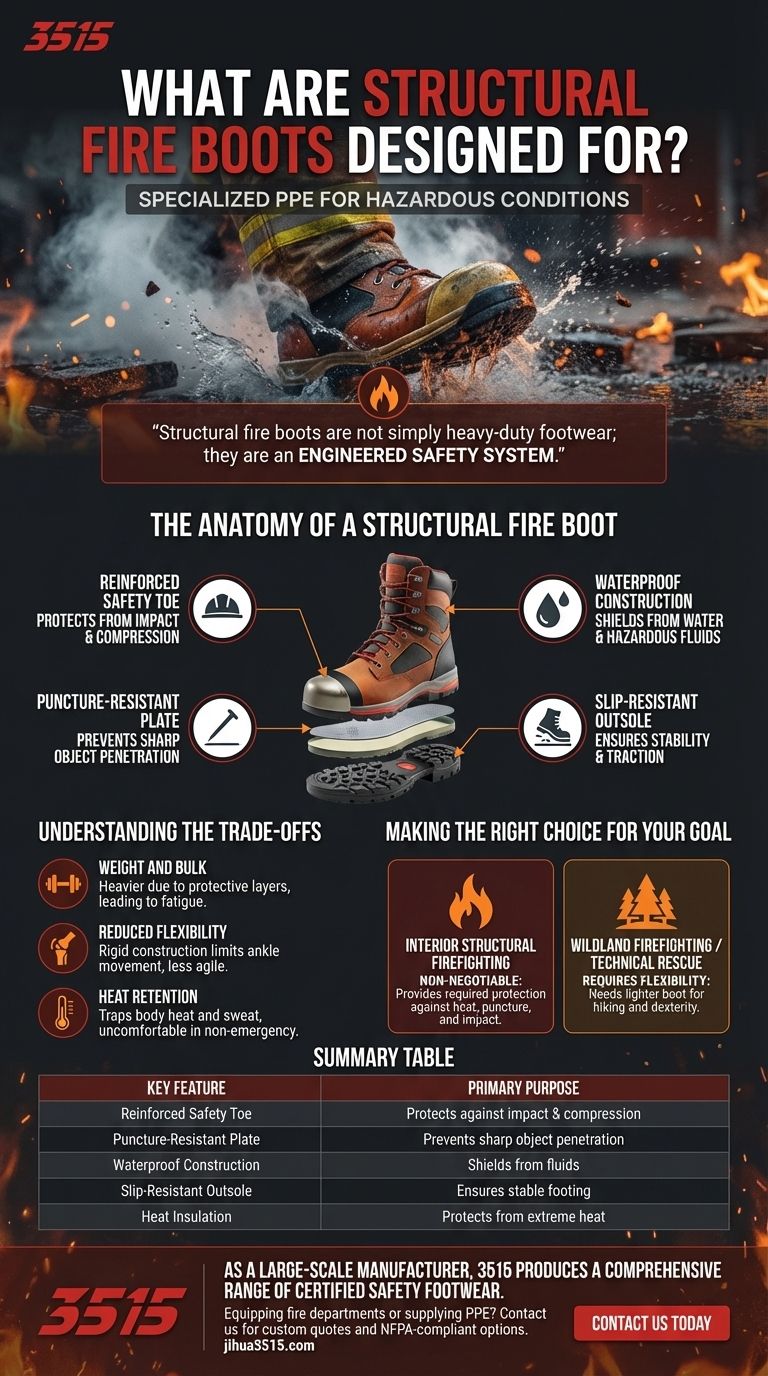

The Anatomy of a Structural Fire Boot

To understand their purpose, it's essential to break down the protective elements that differentiate these boots from any other type of heavy-duty footwear. Each feature directly addresses a specific hazard encountered during an interior fire attack.

Protection from Impact and Compression

The environment inside a burning structure is unstable. Firefighters face the constant risk of falling debris, from collapsing ceiling materials to heavy objects.

Structural fire boots feature a reinforced safety toe, typically made of steel, composite, or other robust materials, to protect the foot from severe impact and compression injuries.

Defense Against Punctures

Floors in a fire scene are often littered with sharp objects like nails, broken glass, and jagged metal from collapsed structures.

A puncture-resistant plate is embedded in the sole of the boot. This crucial layer prevents sharp objects from penetrating the bottom of the foot, which could cause a debilitating injury.

Resisting Water and Hazardous Fluids

Firefighting operations use immense amounts of water, creating a wet and often flooded environment. This water can be contaminated with various chemicals and hazardous materials.

These boots are designed to be completely waterproof. This keeps the firefighter's feet dry to prevent blisters and discomfort, but more importantly, it protects them from exposure to potentially harmful liquids.

Ensuring Stability and Traction

Surfaces inside a fire are unpredictable—they can be wet, oily, or covered in rubble. A slip or fall can be catastrophic for a firefighter and their team.

The outsoles are made from specialized rubber compounds and feature aggressive tread patterns designed for maximum slip resistance, ensuring stable footing on compromised surfaces.

Understanding the Trade-offs: Protection vs. Mobility

While structural fire boots offer unparalleled protection, their design necessitates certain compromises that are important to understand.

Weight and Bulk

The multiple layers of protection, including steel toes and puncture-proof plates, make these boots significantly heavier and bulkier than standard work boots. This can contribute to fatigue during long incidents.

Reduced Flexibility

The rigid construction required for support and protection inherently limits ankle flexibility. This makes them less suitable for activities that require agility or hiking over long distances, such as wildland firefighting.

Heat Retention

While the boots are excellent at protecting from external heat, their insulating properties can also trap body heat and sweat. This can lead to discomfort in non-emergency situations or during prolonged use.

Making the Right Choice for Your Goal

The specific design of a structural fire boot makes it the ideal tool for one job and the wrong tool for another. Understanding this specialization is key to ensuring safety and effectiveness.

- If your primary focus is interior structural firefighting: These certified boots are non-negotiable, providing the required protection against heat, puncture, and impact.

- If your primary focus is wildland firefighting or technical rescue: You would require a different, more flexible boot designed for hiking long distances or providing greater dexterity.

Ultimately, choosing the correct, purpose-built boot is a foundational element of firefighter safety and operational effectiveness.

Summary Table:

| Key Feature | Primary Purpose |

|---|---|

| Reinforced Safety Toe | Protects against impact and compression from falling debris. |

| Puncture-Resistant Plate | Prevents sharp objects from penetrating the sole. |

| Waterproof Construction | Shields feet from water and hazardous fluids. |

| Slip-Resistant Outsole | Ensures stable footing on wet, oily, or unstable surfaces. |

| Heat Insulation | Protects from extreme external heat encountered in fires. |

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients.

Are you equipping a fire department or supplying PPE to first responders? Our production capabilities encompass all types of specialized boots, including NFPA-compliant structural fire boots built with the highest standards of protection and durability.

Contact us today to discuss your specific requirements and receive a custom quote. Let us help you ensure the safety of those who protect our communities.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How should one choose the right engineer boots? A Guide to Fit, Material, and Purpose

- What makes the Mortar boots suitable for corrosive environments? Unmatched Chemical Resistance & Durability

- How should motorcycle boots be worn in relation to pants? A Guide to Safety and Function

- What are the primary dangers of not wearing wildfire boots? The Critical Failure Points That Risk Lives

- What are common contaminants encountered by firefighters that affect boot choice? Select the Right Material for Safety.

- What kind of boots do Wildland firefighters wear? The Ultimate Guide to NFPA 1977 Certified Footwear

- What type of footwear is required for mechanics? The Ultimate Guide to Garage Safety Boots

- What are the advantages and disadvantages of textile uppers in work boots? Find the Right Fit for Your Job