Real-world examples of safety footwear preventing injury are common across all major industries. A steel-toe boot stops a falling brick from crushing a construction worker's foot, specialized chemical-resistant boots prevent severe burns in a lab, and footwear with non-slip soles can avert a catastrophic fall on a wet factory floor or an icy path.

The core principle of footwear safety is not just about wearing a "safety shoe," but about a precise match between the footwear's specific protective features and the predictable hazards of the work environment.

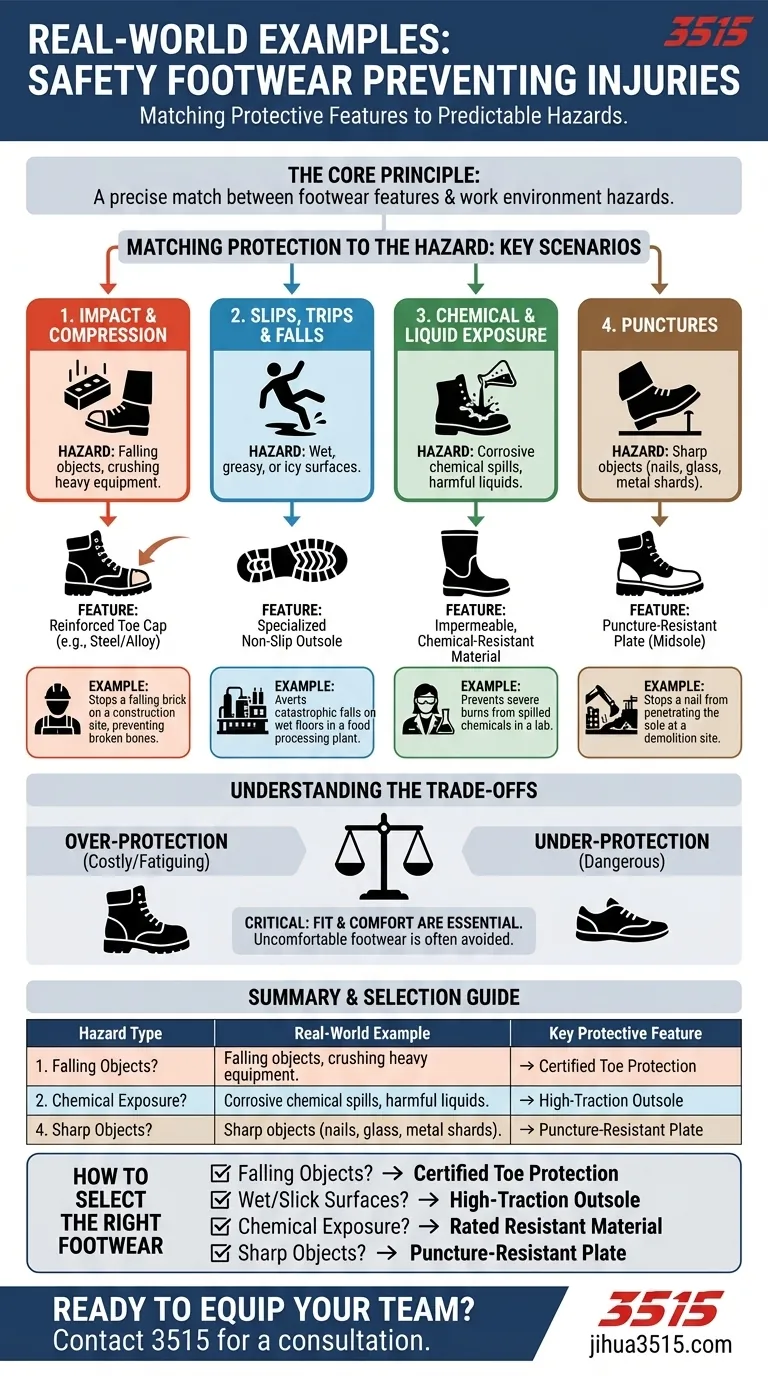

Matching Protection to the Hazard: Key Scenarios

The effectiveness of safety footwear is determined by how well its design neutralizes a specific, identified risk. Each environment presents a unique set of challenges, and the right footwear is engineered to meet them directly.

Protection from Impact and Compression

This is the most classic function of safety footwear. It's designed to protect the foot from falling objects or being crushed by heavy equipment.

The most common example is a steel-toe boot on a construction site. If a tool, brick, or piece of lumber is dropped, the reinforced toe cap distributes the force of the impact, preventing broken bones and severe crushing injuries.

Protection from Slips, Trips, and Falls

Slips and falls are among the most frequent workplace accidents. Specialized outsoles are the primary defense against this pervasive hazard.

In a food processing plant, where floors are often wet or greasy, boots with high-traction, non-slip soles are essential. The tread pattern is engineered to channel liquids away, allowing the sole to maintain a firm grip and prevent dangerous falls.

Similarly, winter footwear with enhanced grip provides critical traction on icy sidewalks and snowy work areas, significantly reducing the risk of falls for postal workers, delivery drivers, and outdoor laborers.

Protection from Chemical and Liquid Hazards

In labs, manufacturing facilities, or hazardous material sites, the danger isn't from impact but from exposure.

A worker in a chemical plant wears boots made of rubber or other non-porous, synthetic materials. If a corrosive chemical spills, these boots create an impermeable barrier, preventing direct skin contact that could cause severe burns or systemic poisoning.

Protection from Punctures

Work environments are often littered with sharp objects that pose a threat from below.

On a demolition site or in a recycling facility, a worker can easily step on a nail, shard of glass, or sharp piece of metal. Footwear with a puncture-resistant plate built into the midsole stops these objects from penetrating the sole and causing a deep, often infected, wound.

Understanding the Trade-offs

Choosing safety footwear is not a one-size-fits-all decision. Selecting the wrong type of protection can be just as problematic as having no protection at all.

The Cost of Over-Protection

Forcing a worker who only needs slip resistance to wear a heavy, steel-toed boot can be counterproductive. The unnecessary weight and bulk can lead to fatigue, reduced mobility, and even a higher likelihood of trips, undermining the goal of safety.

The Danger of Under-Protection

The opposite scenario is far more dangerous. A comfortable, lightweight shoe with a non-slip sole offers zero protection from a 50-pound box falling off a warehouse shelf. A risk assessment must accurately identify the most serious potential hazards, not just the most common ones.

The Importance of Fit and Comfort

Even the most technologically advanced boot is useless if it's not worn. Footwear that is uncomfortable, poorly fitted, or causes blisters will often be avoided or modified by workers, completely negating its protective features.

How to Select the Right Footwear

Your choice must be driven by a clear understanding of your environment's primary risks.

- If your primary hazard is falling objects: Focus on footwear with certified toe protection (steel, alloy, or composite) and consider metatarsal guards for full top-of-foot coverage.

- If your primary hazard is wet or slick surfaces: Prioritize footwear with high-traction, non-slip outsoles specifically rated for your environmental conditions (e.g., oil-resistant, water-channeling).

- If your primary hazard is chemical exposure: Select boots made from materials specifically rated to resist the chemicals you handle, ensuring they are leak-proof.

- If your primary hazard is sharp objects underfoot: Ensure your footwear includes a puncture-resistant plate built directly into the sole.

Ultimately, the right safety footwear is the final, critical line of defense between a worker and a life-altering injury.

Summary Table:

| Hazard Type | Real-World Example | Key Protective Feature |

|---|---|---|

| Impact/Compression | Falling brick on a construction site | Steel-toe cap |

| Slips & Falls | Wet floor in a food processing plant | Non-slip, high-traction outsole |

| Chemical Exposure | Chemical spill in a lab or plant | Chemical-resistant, impermeable material |

| Punctures | Stepping on nails at a demolition site | Puncture-resistant midsole plate |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We provide the precise match of protection your work environment demands—from steel-toe boots for construction to chemical-resistant models for labs.

Contact 3515 today for a consultation and let us help you build a safer workplace.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What causes corns in steel toe boots and how can they be prevented? Master the Perfect Fit to Avoid Pain

- What are the common problems with steel toe boots? How to Prevent Foot Pain & Fatigue

- How can one prevent blisters when wearing steel toe boots? A Complete Guide to Pain-Free Workdays

- Is there any truth to the myth about steel toe boots causing toe injuries upon impact? Debunking Common Safety Concerns

- What are the consequences of not wearing safety shoes? Protect Your Feet from Severe Workplace Injuries