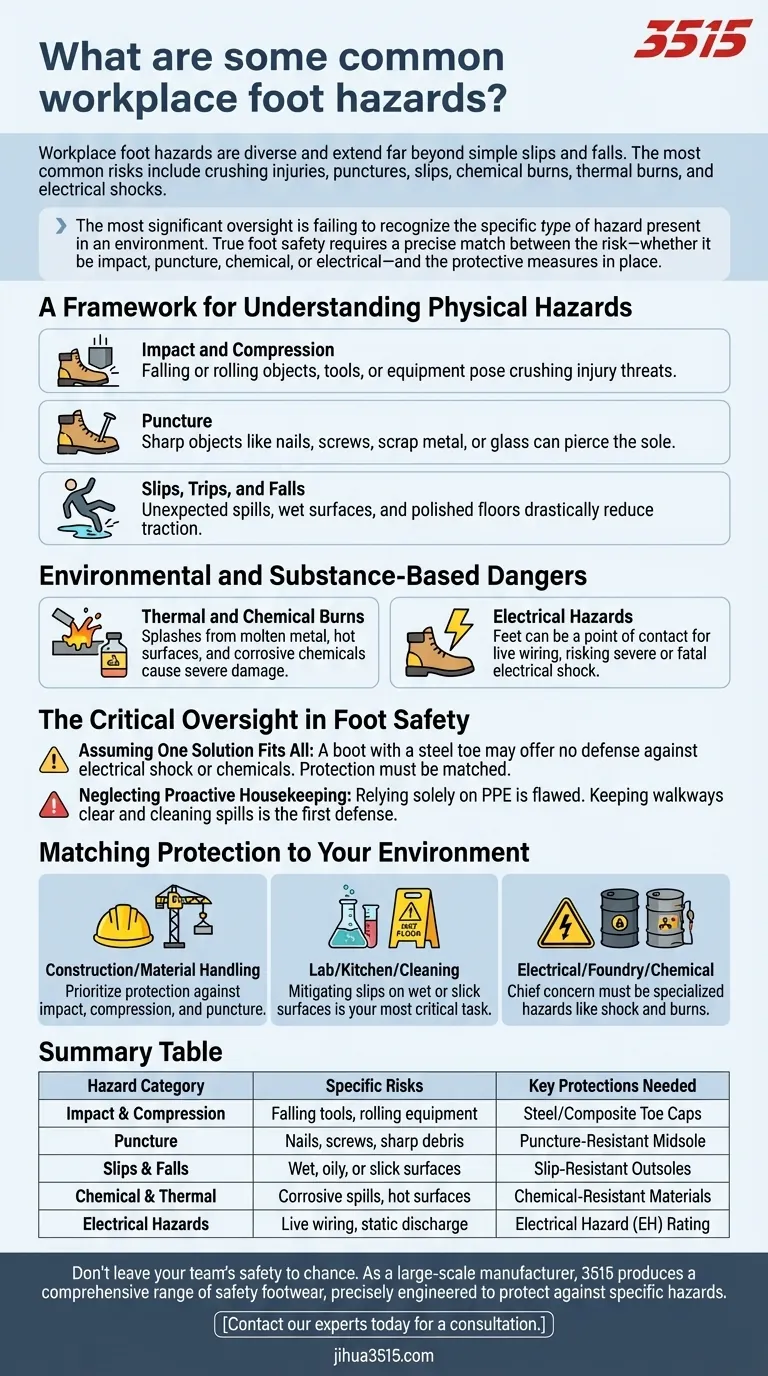

Workplace foot hazards are diverse and extend far beyond simple slips and falls. The most common risks include crushing injuries from falling or rolling objects, punctures from sharp materials left on the ground, and slips on wet or slick surfaces. Workers are also frequently exposed to less obvious dangers such as chemical burns, thermal burns from hot materials, and electrical shocks.

The most significant oversight is failing to recognize the specific type of hazard present in an environment. True foot safety requires a precise match between the risk—whether it be impact, puncture, chemical, or electrical—and the protective measures in place.

A Framework for Understanding Physical Hazards

To effectively mitigate risk, we must first categorize the threats. Physical hazards are often the most visible and involve direct contact that can cause immediate injury.

Impact and Compression

This category involves injuries from forceful contact. Falling or rolling objects, such as tools dropped from a height, unsecured materials on shelves, or moving equipment, pose a significant threat of crushing injuries to the feet.

Puncture

The risk of puncture comes from any sharp object that can pierce the sole of a shoe. This commonly includes stray nails, screws, scrap metal, or shards of glass left on floors, particularly in construction or demolition environments.

Slips, Trips, and Falls

This is one of the most frequent causes of workplace injury. Unexpected spills, wet surfaces from cleaning or weather, and polished floors can all drastically reduce traction and lead to dangerous falls.

Environmental and Substance-Based Dangers

Beyond direct physical impact, the work environment itself can present a range of hazards that are often silent but just as severe.

Thermal and Chemical Burns

Direct contact with certain substances can cause severe damage. This includes splashes from molten metal in foundries, contact with hot surfaces on machinery, and exposure to corrosive chemicals that can eat through standard footwear.

Electrical Hazards

In environments with live wiring or the risk of static discharge, the feet can become a point of contact for an electrical circuit. This creates a severe risk of electrical shock, which can be fatal.

The Critical Oversight in Foot Safety

A reactive approach to foot protection is a common and dangerous mistake. Understanding the nuances of your specific environment is essential for preventing injury.

Assuming One Solution Fits All

Many assume any "safety shoe" is sufficient. However, a boot with a steel toe for impact protection may offer no defense against electrical shock or a chemical spill. The protection must be matched to the specific hazard.

Neglecting Proactive Housekeeping

Many foot hazards are a direct result of a disorderly work area. Relying solely on personal protective equipment (PPE) is a flawed strategy. Keeping walkways clear of objects, cleaning up spills immediately, and securing loose materials are the first and most effective lines of defense.

Matching Protection to Your Environment

Your strategy for foot safety should be dictated by the primary risks in your specific work area.

- If your primary focus is construction or material handling: Prioritize protection against impact, compression, and puncture hazards.

- If your primary focus is a lab, kitchen, or cleaning service: Mitigating slips on wet or slick surfaces is your most critical task.

- If your primary focus is electrical work, foundry, or chemical processing: Your chief concern must be specialized environmental hazards like shock and burns.

A proactive assessment of your specific work environment is the foundation of genuine foot safety.

Summary Table:

| Hazard Category | Specific Risks | Key Protections Needed |

|---|---|---|

| Impact & Compression | Falling tools, rolling equipment | Steel/Composite Toe Caps |

| Puncture | Nails, screws, sharp debris | Puncture-Resistant Midsole |

| Slips & Falls | Wet, oily, or slick surfaces | Slip-Resistant Outsoles |

| Chemical & Thermal | Corrosive spills, hot surfaces | Chemical-Resistant Materials |

| Electrical Hazards | Live wiring, static discharge | Electrical Hazard (EH) Rating |

Don't leave your team's safety to chance. As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, precisely engineered to protect against the specific hazards in your workplace—from impact and puncture to electrical and chemical risks.

Contact our experts today for a consultation. We'll help you select the perfect footwear to mitigate your unique risks and ensure compliance.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- Are steel toe boots inherently bad for your feet? Debunking Myths for Workplace Safety

- What are the common problems with steel toe boots? How to Prevent Foot Pain & Fatigue

- How can one prevent blisters when wearing steel toe boots? A Complete Guide to Pain-Free Workdays

- What types of safety toe boots are available? Find the Perfect Fit for Your Job's Hazards

- Is there any truth to the myth about steel toe boots causing toe injuries upon impact? Debunking Common Safety Concerns