At their core, certified work boots are engineered to prevent a range of serious, work-related foot injuries that can be immediately debilitating. They provide a critical barrier against crushing from heavy objects, punctures from sharp debris on the ground, severe cuts from machinery, electrical shocks from live circuits, and the sprains or fractures that result from slips and falls.

Your work boot is not simply footwear; it is a piece of specialized Personal Protective Equipment (PPE). Understanding the specific hazards it's designed to counter is the first step in ensuring your own safety on the job site.

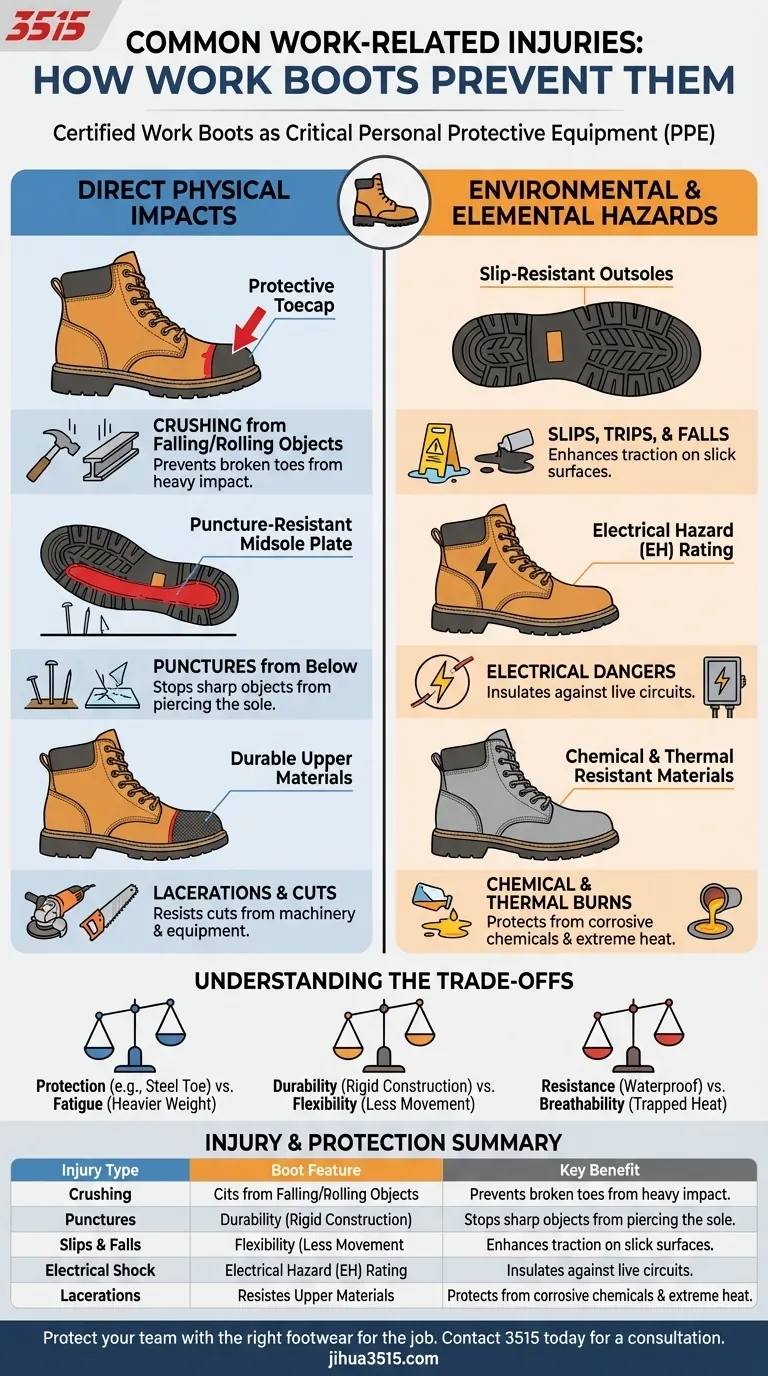

Protection Against Direct Physical Impacts

The most intuitive function of a work boot is to shield the foot from kinetic energy and sharp objects, which are constant threats in many industrial, construction, and warehouse environments.

Crushing from Falling or Rolling Objects

A primary danger in dynamic workplaces is the risk of heavy items falling or rolling onto the foot.

Certified work boots feature a protective toecap (often made of steel, aluminum, or a composite material) designed to withstand significant impact and compression, preventing crushed or broken toes.

Punctures from Below

Job sites are often littered with nails, screws, scrap metal, and other sharp debris that can easily pierce the sole of a standard shoe.

Many work boots include a built-in, puncture-resistant plate in the midsole, which stops sharp objects from penetrating the boot and causing deep, often severe, wounds to the sole of the foot.

Lacerations and Cuts

Operating equipment like chainsaws, grinders, or other unguarded machinery presents a high risk of severe cuts or even severed toes.

The durable upper materials of a work boot, such as thick leather or advanced synthetic fabrics, provide a crucial layer of protection against these types of lacerations.

Mitigating Environmental and Elemental Hazards

Beyond direct impacts, work boots are designed to manage the specific environmental conditions of a workplace, which can be just as dangerous.

Slips, Trips, and Falls

Slippery surfaces from water, oil, or ice are a leading cause of workplace accidents, frequently resulting in sprains, fractures, and more severe injuries.

Work boots utilize specialized slip-resistant outsoles with specific tread patterns and rubber compounds engineered to maintain traction and stability on slick floors, preventing dangerous falls.

Electrical Dangers

For electricians and maintenance workers, accidental contact with a live electrical circuit is a life-threatening risk.

Boots with an Electrical Hazard (EH) rating are made with non-conductive materials that can protect the wearer from open circuits up to a specific voltage, effectively insulating them from the ground.

Chemical and Thermal Burns

Contact with corrosive chemicals, molten metal, or extreme heat sources can cause devastating burns.

Specialized boots are constructed from materials that resist chemical breakdown and provide thermal insulation, protecting the foot from both chemical and heat-related burns.

Understanding the Trade-offs

Selecting the right boot is about matching the features to the hazard. Simply choosing the "most protected" boot can introduce its own set of problems.

Protection vs. Fatigue

Heavier protective features, like steel toes and thick puncture plates, add weight to the boot. Over a long shift, this extra weight can lead to significant leg and back fatigue.

Durability vs. Flexibility

Rigid construction and thick soles that protect against impact and punctures can also reduce the boot's flexibility. This can make tasks that require kneeling or climbing less comfortable.

Resistance vs. Breathability

Waterproof and chemical-resistant membranes are excellent at keeping hazards out, but they can also trap heat and sweat. In hot environments, this can lead to discomfort and skin issues.

Making the Right Choice for Your Hazard

The optimal work boot is the one that provides the necessary protection for your specific environment without adding unnecessary burdens.

- If your primary focus is construction or demolition: Prioritize boots with certified safety toes and puncture-resistant plates to defend against impact and sharp debris.

- If your primary focus is electrical work: Insist on a boot with a clear Electrical Hazard (EH) rating to protect against shock.

- If your primary focus is indoor manufacturing or warehouse logistics: Emphasize a high-quality, slip-resistant outsole to prevent falls on smooth, potentially slick surfaces.

- If your primary focus is outdoor work in wet or cold conditions: Look for excellent waterproofing, insulation, and an aggressive tread pattern for superior traction.

Ultimately, choosing the right work boot is a foundational act of professional self-preservation.

Summary Table:

| Injury Type | Work Boot Protection Feature | Key Benefit |

|---|---|---|

| Crushing Injuries | Protective Toecap (Steel/Composite) | Prevents broken toes from heavy objects |

| Puncture Wounds | Puncture-Resistant Midsole Plate | Stops nails and sharp debris from piercing the foot |

| Slips & Falls | Slip-Resistant Outsoles | Enhances traction on wet or oily surfaces |

| Electrical Shock | Electrical Hazard (EH) Rating | Insulates against live circuits |

| Lacerations | Durable Upper Materials (e.g., Leather) | Protects against cuts from machinery |

Protect your team with the right footwear for the job. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective boots tailored to your specific industry hazards—from construction and electrical work to warehouse logistics. Ensure your workforce's safety and compliance. Contact 3515 today for a consultation and discover how we can equip your business with durable, reliable work boots.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?