When buying new boots, fit is the most important feature. The key to achieving a proper fit is to ensure a snug hold around your heel and instep while leaving enough room for your toes to wiggle freely. This is best accomplished by trying on boots late in the day with the exact socks you plan to wear, as your feet naturally swell.

The right boot fit isn't just about your size number; it's a precise system where your foot, your specific socks, and the boot's internal shape work together. The goal is to create a secure, comfortable hold without painful pressure points.

The Anatomy of a Perfect Fit

Understanding the key contact zones inside a boot is the first step toward diagnosing fit. A boot that feels generally "okay" can still cause significant issues if one of these areas is incorrect.

The Heel Lock: Your Anchor

Your heel should feel comfortably "locked" in place. A small amount of lift while walking is normal during the break-in period, but excessive slipping will cause painful blisters.

This snug fit prevents your foot from sliding forward on declines, which can slam your toes into the front of the boot.

The Toe Box: Room to Move

You must have enough space to wiggle your toes. A cramped toe box restricts circulation and can lead to numbness or long-term foot problems.

If the boot has a safety toe (steel or composite), this space is even more critical. Ensure there is adequate room between the end of your toes and the rigid cap.

The Instep and Width: Secure but Not Strangled

The boot should feel snug across the top of your foot (the instep) and along the sides. This is what holds your foot securely in the boot.

However, "snug" does not mean tight. If you feel intense pressure or pinching, the boot's volume or width is likely wrong for your foot shape.

How to Test a Boot Like a Pro

To get an accurate assessment, you need to simulate the conditions under which you'll wear the boots. Going to a store unprepared is the most common mistake.

Step 1: Time Your Fitting Correctly

Always try on boots in the late afternoon or evening. Feet swell throughout the day from walking and standing, reaching their largest size by the end of the day.

Fitting a boot to your "morning foot" is a recipe for a painfully tight fit by quitting time.

Step 2: Bring the Right Equipment (Your Socks)

The thickness of your sock dramatically alters the fit of a boot. Never try on boots with the thin dress socks you might be wearing to the store.

Bring the actual socks you will wear for the intended activity, whether they are thick merino wool hiking socks or standard-issue work socks. This creates a consistent "sock-boot system."

Step 3: Check Both Feet

Most people have one foot that is slightly larger than the other. Always try on both the left and right boot and size your purchase to the larger foot.

A boot that is slightly too large can be adjusted with lacing or a thicker sock, but a boot that is too small is unusable.

Understanding the Nuances and Trade-offs

A perfect fit involves more than just size. The boot's materials and intended purpose create important trade-offs you must consider.

The Myth of "Perfect Out of the Box"

While a boot should be generally comfortable from the start, very few feel perfect immediately. Stiff materials, particularly full-grain leather, require a break-in period.

During this time, the leather will soften and stretch slightly, conforming to the unique shape of your foot. Expect some initial stiffness, but never accept sharp pain or major pressure points.

Material Matters: Leather vs. Synthetics

Leather boots will stretch and mold to your foot over time, offering a more customized fit in the long run.

Synthetic boots (like nylon or polyester) have a much shorter break-in period but offer very little stretch. The fit you feel in the store is essentially the fit you will always have.

The Impact of Boot Type

The ideal fit changes based on the boot's job. A pull-on Wellington boot requires a snugger fit over the instep to compensate for the lack of laces.

A technical hiking boot needs an uncompromising heel lock to prevent blisters during steep ascents and descents. A work boot needs to accommodate the demands of a specific job site, from safety toes to sole flexibility.

Making the Right Choice for Your Needs

Use your primary goal to prioritize which element of fit is most critical for your decision.

- If your primary focus is all-day work comfort: Prioritize correct width and volume to prevent pressure points during long hours on your feet.

- If your primary focus is technical hiking performance: Prioritize a secure heel lock to prevent your foot from shifting on uneven terrain.

- If your primary focus is casual wear and convenience: Prioritize initial comfort and a balanced fit that doesn't require an extensive break-in period.

Get the fit right, and you are building a foundation for comfort, performance, and safety that lasts.

Summary Table:

| Key Fit Area | What to Look For | Why It Matters |

|---|---|---|

| Heel Lock | Heel feels securely anchored with minimal slippage. | Prevents blisters and stops foot from sliding forward. |

| Toe Box | Enough room to wiggle toes freely, especially with safety toes. | Avoids numbness, circulation issues, and long-term foot problems. |

| Instep & Width | Snug but not tight across the top and sides of the foot. | Ensures secure hold without painful pressure points. |

| Fitting Time | Try on boots in the late afternoon or evening. | Accounts for natural foot swelling throughout the day. |

| Break-In Period | Expect initial stiffness but no sharp pain; materials like leather will mold over time. | Allows the boot to conform to your unique foot shape for a custom fit. |

Ready to Source Boots with the Perfect Fit for Your Customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring we can deliver the precise fit, comfort, and durability your market demands.

Let us help you build a foundation of customer satisfaction with boots that perform. Contact our team today to discuss your manufacturing needs.

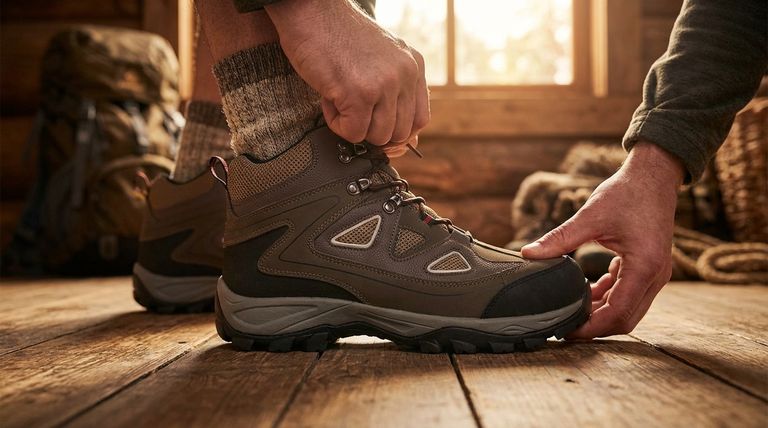

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job