An engineer boot is a classic American style of laceless, pull-on work boot. Characterized by its heavy-duty full-grain leather construction, it features an adjustable buckle strap over the instep and another at the top of its tall "stovepipe" shaft. Originally designed for tough work environments, its rugged durability and distinctive look have made it an iconic choice for motorcyclists.

At its core, the engineer boot is a masterclass in functional design. It solves the need for durable, protective footwear without laces that could snag on machinery or motorcycle controls, blending pure utility with a timeless, rugged aesthetic.

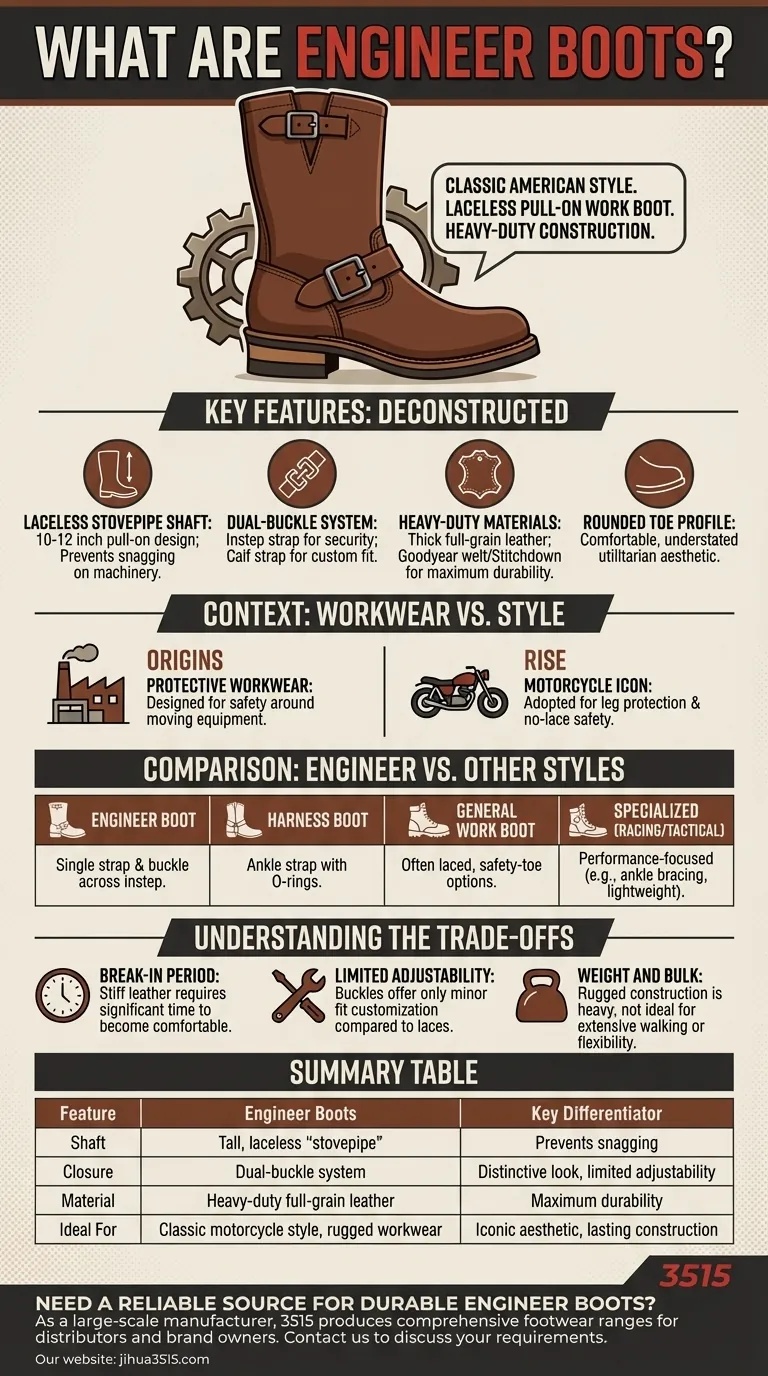

Deconstructing the Engineer Boot: Key Features

The identity of the engineer boot is defined by a few specific, functional components that have remained largely unchanged for decades.

The Laceless Stovepipe Shaft

The boot features a tall, unstructured shaft, typically between 10 and 12 inches. This pull-on, laceless design was critical in work environments to prevent laces from catching in heavy machinery.

The Dual-Buckle System

Two adjustable leather straps are the boot's most recognizable feature. One strap sits across the instep to secure the foot, while a second strap at the top of the shaft allows for a customized fit around the calf.

Heavy-Duty Materials and Construction

Engineer boots are traditionally built from thick, full-grain leather for maximum durability and protection. They often employ robust construction methods like a Goodyear welt or stitchdown, paired with long-lasting rubber outsoles, sometimes specified as oil-resistant neoprene or high-traction Vibram.

The Rounded Toe Profile

The classic silhouette includes a simple, rounded toe. This provides a comfortable fit and contributes to the boot's understated, utilitarian appearance.

The Engineer Boot in Context: Workwear vs. Style

The engineer boot's journey from shop floors to the open road defines its dual identity as both a tool and a symbol.

Origins as Protective Workwear

This boot began as pure workwear in the United States. Its entire design was a direct response to the needs of workers who required durable, protective footwear that was also safe to wear around moving equipment.

The Rise as a Motorcycle Icon

Motorcyclists quickly adopted the engineer boot for the same reasons. The tall shaft protected their lower legs from engine heat and road debris, while the laceless construction eliminated the risk of a lace coming undone and tangling in the bike's controls.

How Engineer Boots Compare to Other Styles

Understanding the engineer boot requires seeing how it differs from other popular boot categories. Its specific features serve a distinct purpose.

Engineer vs. Harness Boots

These two styles are often confused but have a clear visual difference. The engineer boot has a single strap and buckle across the instep. In contrast, a harness boot features a leather strap that wraps around the ankle, secured on both sides by metal O-rings.

Engineer vs. General Work Boots

While engineer boots are a type of work boot, the broader category includes countless variations. Modern work boots often feature laces for a more secure fit, specialized safety-toe construction (like steel toes), and other features designed for specific industrial or construction jobs.

Engineer vs. Specialized Boots (Racing/Tactical)

Specialized boots prioritize performance for a single activity. Racing boots use advanced, abrasion-resistant materials and ankle bracing for maximum protection during aggressive riding. Tactical boots are designed to be lightweight and flexible, prioritizing agility and range of motion for law enforcement or military use.

Understanding the Trade-offs

The classic design of the engineer boot offers distinct advantages but also comes with practical limitations that are important to consider.

The Break-In Period

The heavy, full-grain leather required to make a durable engineer boot is initially very stiff. This often results in a significant break-in period before the boots become truly comfortable.

Limited Adjustability

The laceless design is a core feature, but it offers far less fit customization than a fully laced boot. The buckles provide only minor adjustments at the ankle and calf.

Weight and Bulk

These are heavy, substantial boots. Their rugged construction means they are not ideal for activities that require extensive walking, running, or a high degree of flexibility.

Making the Right Choice for Your Purpose

Selecting the correct boot means aligning its design strengths with your primary goal.

- If your primary focus is classic motorcycle style and durability: The engineer boot is the definitive choice, offering protection and an iconic look.

- If your primary focus is certified on-the-job safety: A modern work boot with a dedicated safety toe and other certified features is the more appropriate option.

- If your primary focus is lightweight agility for patrol or hiking: A tactical boot provides the necessary flexibility and reduced weight that the engineer boot lacks.

Ultimately, the engineer boot remains a master of its specific niche: providing simple, rugged protection in a timeless, laceless form.

Summary Table:

| Feature | Engineer Boots | Key Differentiator |

|---|---|---|

| Shaft | Tall, laceless "stovepipe" | Prevents snagging on machinery/bike controls |

| Closure | Dual-buckle system (instep & calf) | Distinctive look; limited adjustability |

| Material | Heavy-duty full-grain leather | Maximum durability and protection |

| Ideal For | Classic motorcycle style, rugged workwear | Iconic aesthetic and lasting construction |

Need a reliable source for durable engineer boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear, including classic engineer boots, for distributors, brand owners, and bulk clients. Our production capabilities ensure high-quality, durable construction tailored to your needs.

Contact us today to discuss your requirements and discover how we can be your trusted manufacturing partner.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What is the core function of professional safety boots within a construction Health and Safety (H&S) management system? Beyond Protection: Boost Safety & Productivity

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What primary protective functions do industrial safety shoes provide? Maximize Safety in Heavy Machinery Maintenance

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions