In footwear manufacturing, fabric surface treatments are not merely cosmetic; they are functional processes designed to solve specific challenges. The most common treatments fall into three categories: chemical coatings for protection, mechanical finishing for comfort, and lamination for structural integrity during assembly.

The key takeaway is that fabric treatments are a critical engineering step. The choice of treatment is dictated by the fabric's final location in the shoe and the specific performance, comfort, or production problem it is meant to solve.

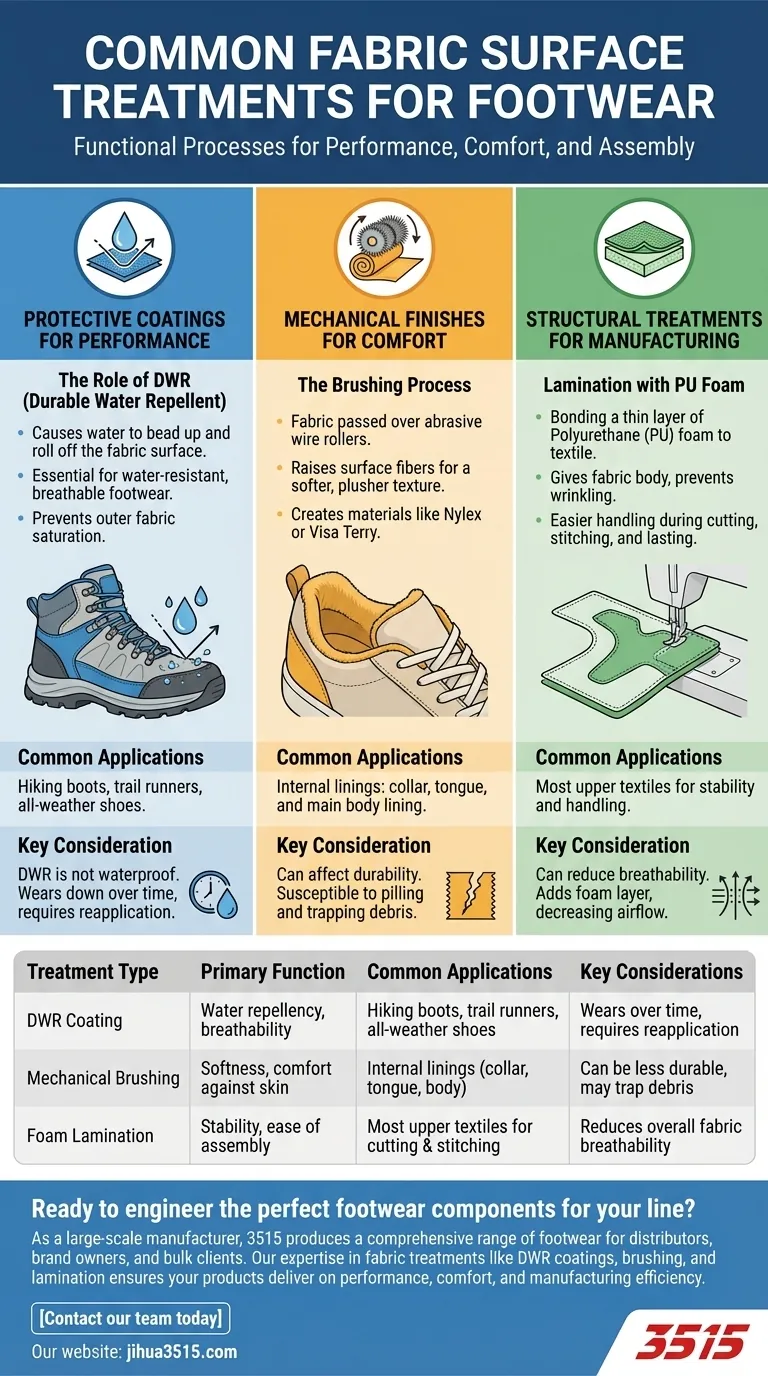

Protective Coatings for Performance

Protective coatings are applied to the surface of a fabric, typically on the shoe's exterior, to shield it from the elements.

The Role of DWR

A Durable Water Repellent (DWR) finish is a chemical treatment that causes water to bead up and roll off the fabric surface.

This treatment is essential for creating water-resistant, breathable footwear. It prevents the outer fabric from becoming saturated, which would compromise the shoe's ability to breathe.

Common Applications

DWR coatings are standard on hiking boots, trail running shoes, and all-weather casual footwear where protection from rain and moisture is a key performance feature.

Mechanical Finishes for Comfort

Mechanical treatments physically alter the texture of the fabric surface, almost always to enhance comfort for the wearer.

The Brushing Process

Brushing is a mechanical process where the fabric is passed over abrasive wire rollers. This technique raises the surface fibers, creating a softer, plusher texture.

Creating Soft Linings

This process is used to create materials like Nylex or Visa Terry. These soft, slightly lofty fabrics are ideal for areas that come in direct contact with the foot.

Common Applications

Brushed fabrics are used almost exclusively for the internal linings of footwear, including the collar, tongue, and main body lining, to provide a comfortable and chafe-free experience.

Structural Treatments for Manufacturing

Some treatments are not intended for the end-user but are critical for the shoe assembly process. They add stability and structure to otherwise flimsy materials.

Lamination with PU Foam

Lamination involves bonding a thin layer of Polyurethane (PU) foam to the back of a textile.

The Goal: Stability and Handling

This foam backing gives the fabric more body, prevents wrinkling, and makes it much easier to handle during cutting, stitching, and lasting (stretching the upper over the shoe form).

Impact on Production Quality

Without this treatment, thin textiles would be difficult to work with, leading to inconsistencies and a less refined final product. It is a crucial step for achieving a smooth, clean look on the finished shoe.

Understanding the Trade-offs

Each treatment offers clear benefits but also comes with inherent limitations that must be considered.

DWR is Not Waterproof

DWR coatings provide water resistance, not full waterproofing. They can also wear down over time due to abrasion and dirt, requiring reapplication to maintain performance.

Brushing Can Affect Durability

While comfortable, brushed fabrics can be more susceptible to pilling and may trap more debris compared to flat-faced textiles.

Lamination Can Reduce Breathability

Adding a layer of foam, even a thin one, will inevitably reduce the overall breathability of the fabric composite. This is a necessary trade-off between manufacturing efficiency and maximum airflow.

Making the Right Choice for Your Goal

Selecting the appropriate treatment is entirely dependent on the intended function of the fabric component.

- If your primary focus is weather resistance for the upper: DWR coatings are the essential starting point for performance footwear.

- If your primary focus is step-in comfort and a premium feel: Brushed fabrics are the industry standard for internal linings.

- If your primary focus is a flawless finish and efficient assembly: Foam lamination is a non-negotiable step for most upper textiles.

Ultimately, understanding these fundamental treatments allows you to engineer footwear components for their specific, intended purpose.

Summary Table:

| Treatment Type | Primary Function | Common Applications | Key Considerations |

|---|---|---|---|

| DWR Coating | Water repellency, breathability | Hiking boots, trail runners, all-weather shoes | Wears over time, requires reapplication |

| Mechanical Brushing | Softness, comfort against skin | Internal linings (collar, tongue, body) | Can be less durable, may trap debris |

| Foam Lamination | Stability, ease of assembly | Most upper textiles for cutting & stitching | Reduces overall fabric breathability |

Ready to engineer the perfect footwear components for your line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in fabric treatments like DWR coatings, brushing, and lamination ensures your products deliver on performance, comfort, and manufacturing efficiency.

Contact our team today to discuss how we can bring your specific footwear vision to life with precision and quality.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job