First, I need to understand the user's real need. Are they just curious, or are they trying to solve a practical problem? I'll assume they're dealing with premature boot failure or are trying to optimize their PPE program. My goal is to give them actionable insights.

I'm starting by breaking down their question into key components. They want to know the common causes of safety boot damage. The source material is a list, but I can't just repeat that. I've got to organize it, explain the "why," and go beyond a simple regurgitation.

I'm thinking, "how can I present this information in a way that's immediately useful?" I'll start with a concise answer to the question. Then, I'll structure the response with clear headings and short, easy-to-digest paragraphs. I'll make sure to highlight the critical information.

I'm going to categorize the causes of damage into logical groups: things outside the user's control (the environment), things they can control (user behavior and care), and inherent limitations of the materials. That way, the answer becomes a preventative guide, which is what the user actually needs.

For example, I'll emphasize that "incorrect spec" means matching the boot to the job site. High heat means "don't wear a leather boot on a foundry floor." Improper washing means "don't use harsh chemicals." I'm also going to address the "inevitable lifecycle," which means all boots will wear out eventually, but you can dramatically increase their lifespan with proper care.

I need to be empathetic and clear. I don't want to come across as overly technical. I'll use analogies, such as comparing a boot sole to a car tire, to illustrate the points. I'm going to provide practical tips, like rotating boots and inspecting laces.

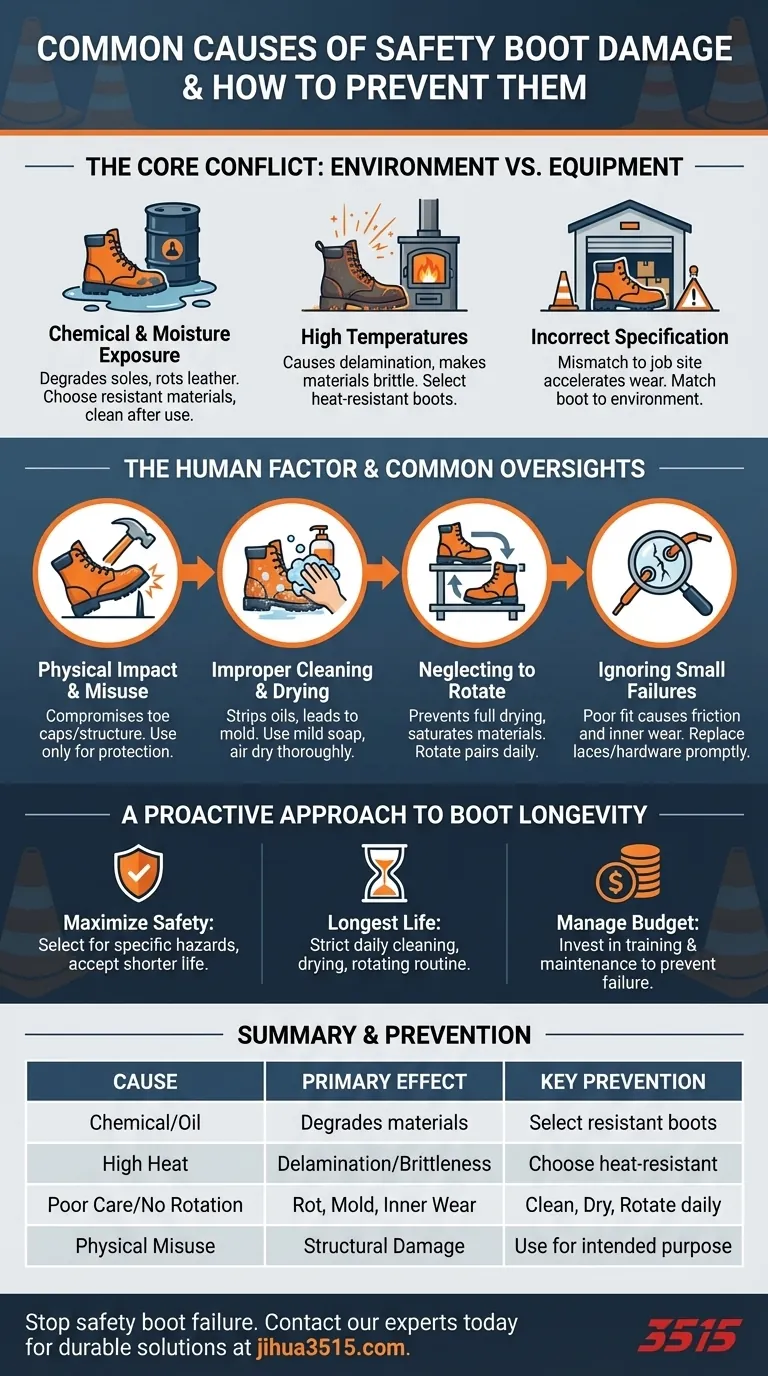

Finally, I'll end with a call to action. I'll offer specific advice based on the user's priorities – safety, longevity, or budget. The main point is that by understanding these factors and selecting appropriate boots, the user can get the maximum safety and utility from their investment. The most common causes of safety boot damage stem from three primary areas: a mismatch between the boot and its working environment, improper care and maintenance by the user, and the natural degradation of materials over time. Specific factors include repeated exposure to high temperatures or chemicals, incorrect cleaning methods, physical abuse, and sudden impacts that compromise the boot's structural integrity.

The central takeaway is that safety boots rarely fail from a single cause. Damage is typically the result of accumulated stress from a combination of environmental exposure, user habits, and the inherent limitations of the materials, making proactive selection and proper maintenance your most powerful tools.

The Core Conflict: Environment vs. Equipment

The most significant factor in a safety boot's lifespan is how well its design matches the demands of your work environment. A fundamental mismatch is the fastest path to premature failure.

The Impact of Incorrect Specification

A boot designed for a dry warehouse environment lacks the robust waterproofing, chemical resistance, or sole compounds needed for a heavy industrial or outdoor construction site. Using the wrong boot for the job guarantees accelerated wear on seams, soles, and upper materials.

The Damage from High Temperatures

Constant exposure to high heat, such as in welding, paving, or foundry work, can have a devastating effect. Heat causes the adhesives that bond the sole to the upper to soften and fail, leading to delamination. It can also cause leather to dry out and crack or rubber components to become brittle.

The Slow Creep of Chemical and Moisture Exposure

Prolonged contact with chemicals, oils, or even just water can degrade boot materials. Solvents can break down sole compounds, while constant dampness can cause leather to rot and stitching to weaken. Without proper cleaning and drying, moisture becomes a persistent threat to the boot's structure.

The Human Factor: How Wearer Habits Cause Damage

Even the most well-specified boot will fail if it is not cared for properly. The user's daily habits play a critical role in the footwear's longevity.

Acute Damage from Impacts and Misuse

Obvious damage comes from acute events like a sharp object piercing the sole or a heavy load crushing the toe cap. While the boot may have protected the wearer, its safety features are now compromised. Using a boot to kick objects or as a makeshift hammer also constitutes misuse, placing stress on seams and materials in ways they were not engineered to handle.

Chronic Damage from Improper Care

This is the most common and preventable form of wear. Washing boots with harsh detergents can strip protective oils from leather. Failing to clean off mud and debris allows abrasive particles to wear away at materials.

The Critical Role of Drying and Storage

Storing boots while they are still wet is a primary cause of material degradation. This traps moisture, which can lead to mold, rot, and the breakdown of adhesives and natural fibers. Proper storage in a dry, ventilated area is non-negotiable for longevity.

Common Oversights That Accelerate Failure

Beyond the major causes, several smaller oversights can significantly shorten the life of your safety footwear. Addressing these is often the key to maximizing your investment.

Neglecting to Rotate Footwear

Wearing the same pair of boots every single day prevents them from ever fully drying out. Perspiration and environmental moisture saturate the materials. Rotating between two pairs gives each one 24-48 hours to air out, dramatically extending the life of both.

Ignoring Small Points of Failure

Worn-out laces or broken eyelets are often ignored, but they prevent the boot from being secured properly. An improper fit leads to excessive movement of the foot inside the boot, causing friction that wears down the inner lining prematurely.

The Inevitability of Natural Aging

All materials have a finite lifespan. Adhesives can become brittle, and sole compounds like polyurethane (PU) can suffer from hydrolysis, a chemical breakdown that causes the sole to crumble. This can happen even to a boot sitting in a box if it is past its effective shelf life.

A Proactive Approach to Boot Longevity

Making the right choice depends on understanding your specific priorities, from maximizing safety to managing a budget.

- If your primary focus is maximum safety in a hazardous environment: Prioritize selecting a boot specifically rated for the unique chemical, temperature, and impact risks you face, accepting that a shorter lifespan is a necessary trade-off for protection.

- If your primary focus is getting the longest possible life from your boots: Implement a strict daily routine of cleaning, drying, and rotating your footwear, and condition the leather or treat the fabric uppers regularly.

- If your primary focus is managing a team's PPE budget: Invest in training on correct boot selection for the task and proper maintenance, as preventing premature failure is far more cost-effective than frequent replacement.

By treating your safety footwear as the critical piece of engineered equipment it is, you ensure it protects you effectively for its entire intended lifespan.

Summary Table:

| Common Cause of Damage | Primary Effect on Boot | Key Prevention Tip |

|---|---|---|

| Chemical/Oil Exposure | Degrades sole compounds & upper materials | Select boots with specific chemical resistance ratings |

| High Temperatures | Causes delamination & makes materials brittle | Choose heat-resistant boots for welding/foundry work |

| Improper Cleaning/Drying | Leads to rot, mold, and weakened stitching | Clean with mild soap; air dry away from direct heat |

| Physical Impact & Misuse | Compromises toe caps and structural integrity | Use boots only for their intended protective purpose |

| Poor Fit & Lack of Rotation | Accelerates inner lining wear from friction | Ensure correct size; rotate pairs to allow for drying |

Stop safety boot failure from impacting your team's safety and budget. As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our expertise ensures you get the right boots—engineered for specific hazards and built to last—maximizing protection and reducing replacement costs. Contact our experts today for a consultation on durable, high-performance safety footwear solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Premium Waterproof Nubuck Safety Boots for Wholesale

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job