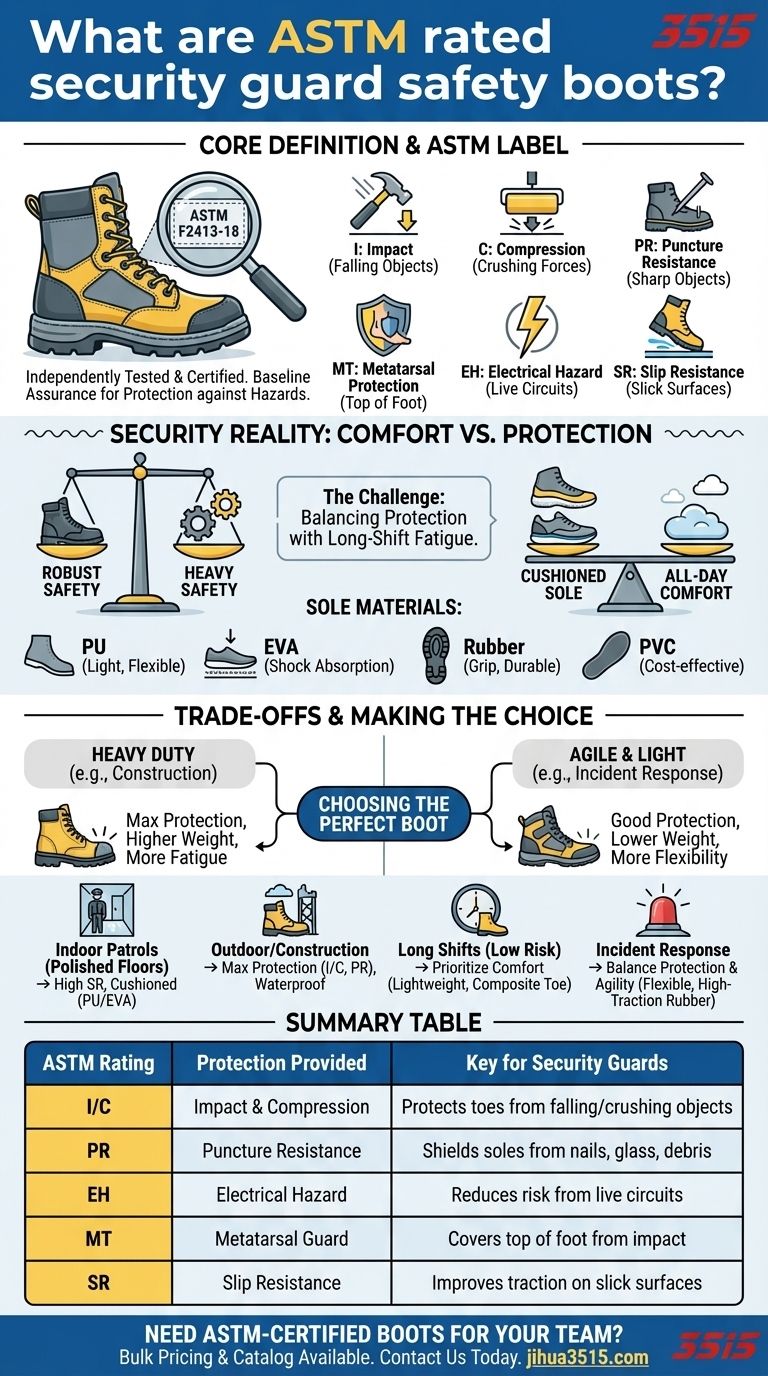

At its core, an ASTM-rated safety boot is footwear that has been independently tested and certified to meet specific safety standards set by the American Society for Testing and Materials. These standards verify a boot's ability to protect the wearer from a range of common workplace hazards, including impact from falling objects, compression from heavy equipment, punctures from sharp items, and slips on slick surfaces. For a security guard, this rating is the baseline assurance that their footwear provides a verified level of protection.

The term "ASTM-rated" is not a single feature but a confirmation that the boot meets specific, labeled safety criteria. The key is to move beyond the general rating and understand which specific protections are essential for the unique demands of a security guard's role, balancing robust safety with all-day comfort.

Deconstructing the ASTM Label: What Do the Ratings Mean?

When you look for safety footwear, the ASTM label is your guide to its protective capabilities. This information is typically found on a tag sewn into the tongue or interior lining of the boot.

The Foundation: Impact and Compression

The most fundamental feature of a safety boot is its protective toe cap. ASTM standards specify precise levels of resistance to ensure your feet are safe from common worksite dangers.

- Impact (I): This rating signifies protection against falling objects.

- Compression (C): This rating measures the boot's ability to withstand crushing or rolling forces.

These are the non-negotiable basics for most hazardous environments and are required by agencies like OSHA for protective footwear.

Beyond the Toe Cap: Essential Protections

A security role often involves more than just impact risk. The job demands awareness of various environmental hazards, and ASTM has ratings for these as well.

- Puncture Resistance (PR): A plate in the midsole protects against sharp objects like nails or glass from piercing the sole.

- Metatarsal Protection (MT): This adds a guard over the top of the foot (the metatarsal bones), protecting it from impact.

- Electrical Hazard (EH): EH-rated boots are designed with non-conductive soles and heels to protect against accidental contact with live electrical circuits.

- Slip Resistance (SR): While not always a specific ASTM code on the label, slip resistance is a critical performance test, especially for guards patrolling smooth or wet surfaces.

Translating Standards into a Security Guard's Reality

A rating on a tag is meaningless if it doesn’t address the day-to-day realities of the job. Security work is unique, often blending long periods of standing with the potential for sudden, dynamic action.

The Primary Challenge: All-Day Comfort and Support

Few professionals spend more time on their feet than security guards. A boot that offers excellent protection but causes fatigue and pain after a few hours is a liability, not an asset.

Look for features like superior shock absorption and cushioning. This is where the sole's material becomes a critical factor in your decision.

Sole Materials Explained

The material used for the outsole directly impacts a boot's comfort, durability, and grip.

- Polyurethane (PU): A fantastic choice for guards. It's lightweight, flexible, and wear-resistant, offering good comfort for long shifts.

- Ethylene Vinyl Acetate (EVA): Often found in the midsole, EVA provides excellent shock absorption, reducing the strain on your feet and joints.

- Rubber: Offers excellent flexibility, waterproofing, and superior grip on slippery surfaces. It can be heavier than synthetic options.

- Polyvinyl Chloride (PVC): A cost-effective and comfortable option that is well-suited for long hours of standing on predictable indoor surfaces.

Preparing for the Environment: Waterproofing

If your post involves any outdoor patrols, waterproofing is essential for both comfort and health. While not an ASTM designation itself, it is often found in boots with higher European (EN) ratings like S2 or S3, which indicate a water-resistant upper.

Understanding the Trade-offs: Protection vs. Agility

Choosing the perfect boot involves balancing competing needs. The safest possible boot is not always the best tool for the job.

The Weight of Safety

A boot with a steel toe, steel puncture plate, and heavy-duty rubber sole offers maximum protection. However, that weight adds up over a 10- or 12-hour shift, leading to significant fatigue. Modern composite toe caps can meet the same ASTM impact standards with a notable reduction in weight.

Flexibility for Movement

A rigid, ultra-protective boot may be ideal for a stationary post on a construction site. However, a guard who needs to move quickly, climb stairs, or respond to an incident requires a boot with greater flexibility to allow for natural foot movement and agility.

Navigating the Jargon

You may see other markings like "EN ISO 20345" and a "CE" mark. These are European standards, functionally similar to ASTM in that they test for hazards like impact (200 joules) and compression. The presence of these marks simply confirms the boot meets international safety criteria.

Making the Right Choice for Your Role

Focus on the specific demands of your assignment to select a boot that serves you best.

- If your primary focus is indoor patrols on polished floors: Prioritize boots with a high slip-resistance rating and excellent cushioning from PU or EVA soles.

- If your primary focus is outdoor or construction site security: You need maximum protection, including a safety toe (Impact/Compression), puncture resistance (PR), and waterproofing.

- If your primary focus is long shifts with low physical risk: Comfort is paramount. Look for lightweight boots with superior shock absorption and support, such as those with a composite toe.

- If your primary focus is incident response: Seek a balance of protection, slip resistance, and agility. A lighter, more flexible boot with a composite toe and a high-traction rubber sole is an ideal choice.

Ultimately, choosing the right boot is about matching the specific, verified ASTM protections to the real-world demands of your post.

Summary Table:

| ASTM Rating | Protection Provided | Key for Security Guards |

|---|---|---|

| I/C | Impact & Compression | Protects toes from falling/crushing objects |

| PR | Puncture Resistance | Shields soles from nails, glass, sharp debris |

| EH | Electrical Hazard | Reduces risk from live circuits |

| MT | Metatarsal Guard | Covers top of foot from impact |

| SR | Slip Resistance | Improves traction on slick surfaces |

Need ASTM-Certified Safety Boots for Your Security Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-rated footwear for distributors, brand owners, and bulk clients. Our boots combine verified safety (impact, compression, puncture resistance) with all-day comfort—perfect for long security shifts.

We offer:

- Lightweight composite toes for agility

- Slip-resistant outsoles for indoor/outdoor patrols

- Waterproof options for harsh weather conditions

Get durable, compliant safety boots tailored to your security needs. Contact us today for bulk pricing and catalog!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do specialized safety shoes protect against battery maintenance injuries? Prevent Impact and Chemical Burns

- What type of safety boots should a general construction worker wear? Choose the Right Boot for Maximum Protection

- Why is strict compliance with standards like CNS 20345 essential for safety shoe production? Ensure Industrial Safety

- How safety and reliability impact protective footwear marketing vs. status attributes? Elevate Security over Image

- Why is an Inertial Measurement Unit (IMU) integrated into smart assistive footwear? Unlocking Precision Navigation

- What are key scenarios requiring safety footwear? Protect Your Workforce from Hazards

- How do professional safety shoes address dual risks in mechanical manufacturing? Stay Protected on Wet & Debris-Filled Floors

- Why is conformance to protective footwear standards important? Protect Workers & Ensure Legal Compliance