In hazardous environments, standards are not guidelines; they are the bedrock of safety. Conformance to protective footwear standards is crucial because it provides verifiable proof of a shoe's ability to protect against specific workplace dangers. This ensures worker safety, satisfies legal and regulatory obligations like those from OSHA, and establishes a clear benchmark for quality and performance.

Protective footwear standards transform the abstract concept of "safety" into a measurable, verifiable, and legally defensible system. They provide a common language of trust between manufacturers, employers, and workers, backed by independent testing and clear labeling.

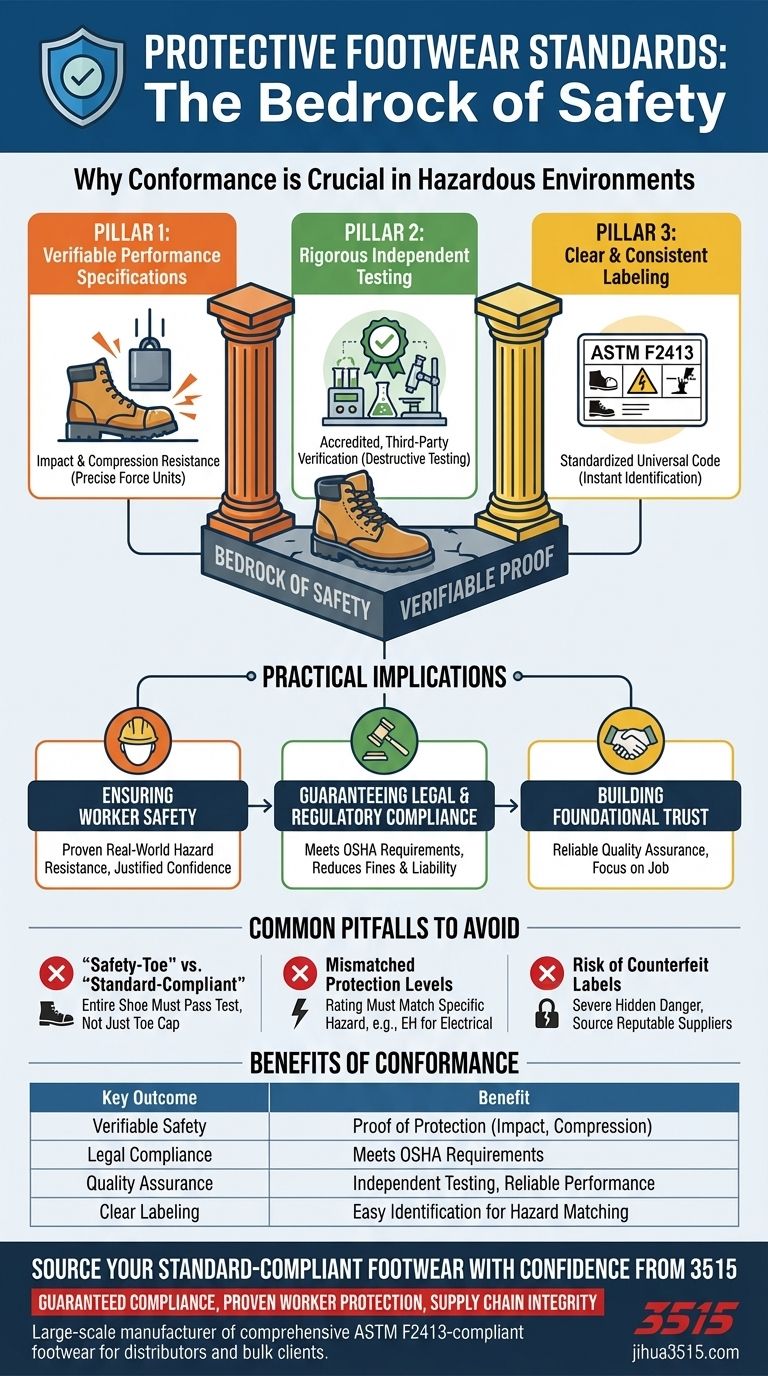

Beyond the Label: The Three Pillars of a Safety Standard

To understand why conformance is so important, you must first understand what a standard truly represents. It's a comprehensive system designed to remove guesswork and replace it with objective proof.

Pillar 1: Verifiable Performance Specifications

A safety standard isn't a vague endorsement. It contains highly specific, physical requirements that a boot must meet.

These include metrics like impact resistance (how it handles a falling object) and compression resistance (how it protects the foot from a rolling object), measured in precise units of force.

Pillar 2: Rigorous Independent Testing

Conformance is not based on a manufacturer's internal claims. The footwear must be sent to an accredited, independent laboratory to undergo destructive testing.

This third-party verification is critical because it removes bias and ensures the footwear performs as advertised under controlled, repeatable conditions.

Pillar 3: Clear and Consistent Labeling

Once a footwear model passes testing, it receives a standardized label (e.g., ASTM F2413). This label acts as a universal code.

It allows a safety manager, worker, or OSHA inspector to instantly identify the specific protections the shoe offers (e.g., steel toe, electrical hazard, puncture resistance) without ambiguity.

The Practical Implications of Conformance

These three pillars work together to create tangible benefits that protect both workers and the organizations they work for.

Ensuring Worker Safety

Conformance means a boot has been proven to withstand the real-world hazards it is rated for. It's the difference between hoping a boot is strong and knowing it can resist a 75-pound impact.

This gives employers and workers justified confidence that the equipment will perform as expected when an incident occurs.

Guaranteeing Legal and Regulatory Compliance

Regulatory bodies like the Occupational Safety and Health Administration (OSHA) require employers to provide protective equipment that meets consensus industry standards.

Using standard-compliant footwear is a primary way to meet this legal obligation, significantly reducing the risk of fines, citations, and liability in the event of an accident.

Building Foundational Trust

Standards create a reliable system of quality assurance. Employers can trust they are providing legitimate protection, and employees can trust that the gear they wear is safe.

This removes doubt and allows everyone to focus on the job at hand, knowing the foundational safety measures are in place.

Common Pitfalls to Avoid

Simply buying a "work boot" is not enough. Understanding the nuances of conformance is key to avoiding common and dangerous mistakes.

"Safety-Toe" vs. "Standard-Compliant"

A boot can have a steel toe cap but still fail to meet the standard. The entire shoe—including its construction, sole, and materials—must pass the full battery of tests for impact and compression.

Mismatched Protection Levels

A standard-compliant boot is only effective against the specific hazards it is rated for. A boot rated for impact resistance (I/75 C/75) offers no protection from electrical shock unless it also carries the EH rating. Always match the label's codes to your site's specific hazard assessment.

The Risk of Counterfeit Labels

The integrity of the entire system relies on authentic products. Sourcing footwear from unreputable suppliers introduces the risk of counterfeit goods with falsified safety labels, creating a severe and hidden danger for workers.

Making the Right Choice for Your Goal

Choosing the right protective footwear requires matching the standard to your specific operational risks.

- If your primary focus is general safety and OSHA compliance: Look for footwear that clearly meets the current ASTM F2413 standard, ensuring the label is visible inside the shoe.

- If your primary focus is a specific hazard (e.g., electrical, puncture): Verify that the standard's specific codes for those protections (like EH or PR) are present on the boot's label.

- If your primary focus is procurement and quality control: Always purchase from reputable manufacturers and distributors who can provide a Declaration of Conformity document upon request.

Ultimately, standards-compliant footwear isn't an expense; it's a non-negotiable investment in the safety and integrity of your operation.

Summary Table:

| Benefit of Conformance | Key Outcome |

|---|---|

| Verifiable Safety | Proof of protection against specific hazards (impact, compression, etc.) |

| Legal Compliance | Meets OSHA requirements, reducing fines and liability |

| Quality Assurance | Independent testing ensures consistent, reliable performance |

| Clear Labeling | Easy identification of protections (e.g., EH, PR) for hazard matching |

Source Your Standard-Compliant Footwear with Confidence from 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-compliant footwear for distributors, brand owners, and bulk clients. We ensure every pair meets rigorous standards for impact resistance, electrical hazard protection, and more, backed by verifiable testing.

Our manufacturing capabilities encompass all types of safety shoes and boots, providing:

- Guaranteed Compliance: Mitigate your legal risks and ensure OSHA adherence.

- Proven Worker Protection: Offer your workforce footwear with independently verified safety performance.

- Supply Chain Integrity: Eliminate the risk of counterfeit labels with reliable, high-volume production.

Protect your workers and your business. Contact our team today to discuss your protective footwear needs.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What are the main materials used in safety-toe boots? Steel, Composite, or Alloy?

- What does the impact rating in safety toe boots mean? Choose the Right Protection for Your Job

- What are the advantages of Goodyear welted safety shoes? Unmatched Durability & Repairability

- What are the basic ratings of security guard safety boots? A Guide to EN ISO 20345 Standards

- Is there a connection between toe material and electrical hazard ratings in boots? The Truth About Boot Safety

- How do oilfield safety shoes contribute to worker productivity? Boost Focus & Reduce Fatigue

- What are the benefits of waterproofing liners in safety shoes? Achieve Superior Foot Protection & Comfort

- How can the lifespan of work shoes be extended? A Proactive Maintenance Guide