In the 1980s, a pivotal advancement in fabric technology was the perfection and widespread adoption of solution-dyed synthetic yarns, most notably nylon. This innovation allowed for the creation of textiles with unprecedented colorfastness and durability, meeting the demands of high-performance applications from rugged workwear to military gear.

The key technological shift of the 1980s was not just about creating new materials, but about fundamentally changing how performance characteristics, like permanent color, were integrated into the very structure of the fabric fiber itself.

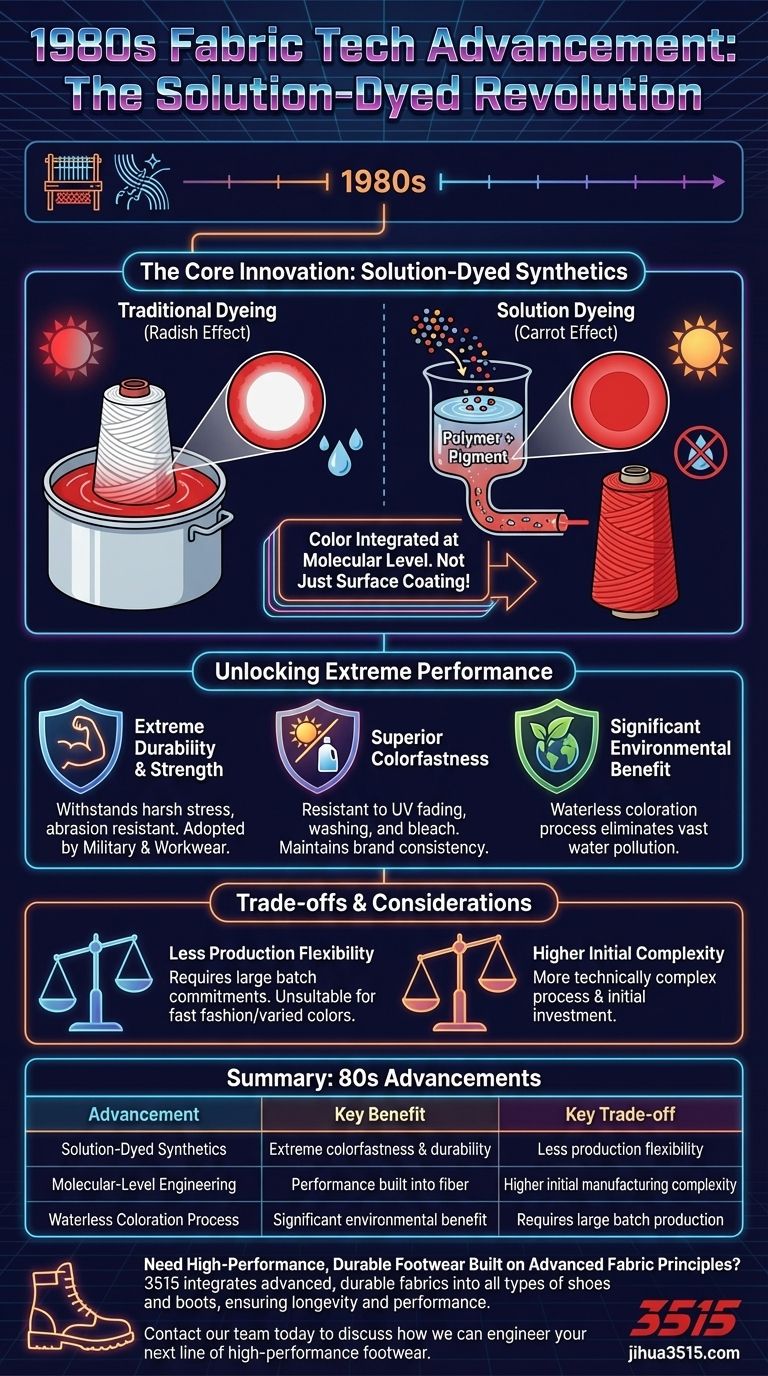

The Core Innovation: Solution-Dyed Synthetics

The development of advanced solution-dyed fibers represented a move away from superficial treatments and toward engineering performance at a molecular level. This created fabrics that were inherently more resilient than their predecessors.

What is Solution Dyeing?

Traditional dyeing involves dipping fully formed yarn or fabric into a vat of dye, which coats the surface of the fibers.

Solution dyeing is a fundamentally different process. The color pigment is mixed into the liquid polymer solution before the synthetic fiber, like nylon, is even created.

Think of it as the difference between a radish (red on the outside, white on the inside) and a carrot (orange all the way through). Solution-dyed fibers have color integrated throughout their entire cross-section.

The Problem It Solved: Color That Lasts

A primary benefit of this technique is superior colorfastness. Because the color is locked into the fiber's structure, it is exceptionally resistant to fading from UV sunlight, washing, bleach, and abrasion.

This solved a critical problem for outdoor and tactical gear, where color integrity is essential for everything from brand consistency to effective camouflage.

Unlocking Extreme Durability

Brands like Carhartt and the U.S. military adopted this technology for its extreme ruggedness. When combined with the inherent strength of nylon, solution dyeing resulted in fabrics that could withstand harsh environmental and physical stress without degrading.

The color wouldn't rub off, and the material was built for high-stakes environments like construction sites and combat zones.

Understanding the Trade-offs

While revolutionary, this technology came with its own set of considerations that influenced its application and production scale.

Reduced Flexibility in Production

The main drawback of solution dyeing is a lack of flexibility. Since the color is added at the very beginning of the manufacturing process, producers must commit to large batches of a single color.

This makes it less suitable for fast-fashion or product lines that require a wide, rapidly changing color palette.

Higher Initial Complexity

The process of integrating pigment into a chemical polymer solution is more technically complex and requires a higher initial investment than simply running finished fabric through a dye bath.

A Surprising Environmental Benefit

Despite the complexity, solution dyeing is significantly better for the environment. Traditional vat dyeing uses and pollutes vast quantities of water.

By adding color before the fiber is extruded, the solution dyeing process almost entirely eliminates the use of water for coloration, a major ecological advantage.

The Legacy of 1980s Fabric Innovation

The principles established in the 1980s set the stage for modern performance textiles. Understanding this context helps in selecting the right material for a specific need.

- If your primary focus is extreme durability and color retention: The lesson from this era is to seek out solution-dyed synthetics, as the performance is engineered directly into the fiber.

- If your primary focus is manufacturing efficiency for diverse colorways: You should recognize that the trade-off for solution dyeing's performance is less production flexibility, making traditional dyeing methods more practical for smaller, varied batches.

This 1980s innovation marked the moment when fabric evolved from a simple covering into a piece of high-performance engineered equipment.

Summary Table:

| Advancement | Key Benefit | Key Trade-off |

|---|---|---|

| Solution-Dyed Synthetics | Extreme colorfastness & durability | Less production flexibility for colors |

| Molecular-Level Engineering | Performance built into the fiber | Higher initial manufacturing complexity |

| Waterless Coloration Process | Significant environmental benefit | Requires large batch production |

Need High-Performance, Durable Footwear Built on Advanced Fabric Principles?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities, informed by decades of material innovation, allow us to integrate advanced, durable fabrics into all types of shoes and boots, ensuring your products meet the highest standards for longevity and performance.

Contact our team today to discuss how we can engineer your next line of high-performance footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why is Structural Equation Modeling (SEM) used for eco-friendly footwear? Analyze Consumer Trends with Scientific Rigor

- What role do Flexible Printed Circuits (FPC) play in plantar pressure monitoring? Powering Smart Footwear Reliability

- What is the importance of disclosing Tier 2 supplier information? Secure Quality and Ethics in Footwear Production

- What is the purpose of the high shaft in Western riding boots? Essential Protection & Performance

- Why is it necessary to use lightweight and adaptable soft materials in insoles? Enhance Comfort & Sensory Stability

- What is the significance of ergonomic design in high-frequency use PPE? Enhance Worker Safety and Compliance

- What makes Cordura so durable? The 3-Step Science of Extreme Fabric Toughness

- How does the digitalization of technical guidance benefit footwear manufacturing? Drive Efficiency and Quality