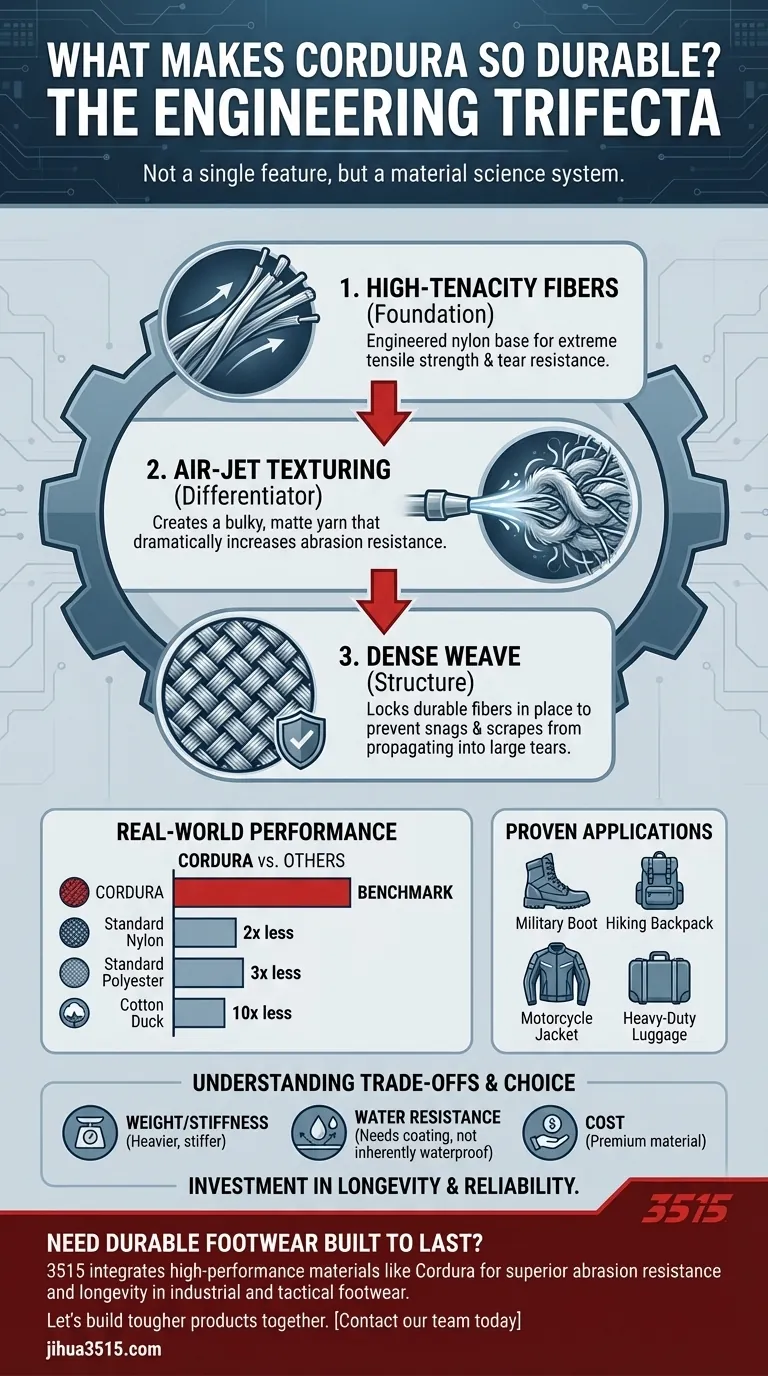

At its core, Cordura's legendary durability is not the result of a single feature, but a trifecta of material science. It begins with high-tenacity nylon fibers engineered for extreme tensile strength, which are then bulked up through an air-jet texturing process. Finally, these rugged yarns are locked into a tight, dense weave, creating a fabric that is exceptionally resistant to abrasions, tears, and scuffs.

The key takeaway is that Cordura isn't just a strong material; it's a complete system. The specific combination of engineered fibers, a unique texturing process, and a dense weave work together to create a level of toughness that standard fabrics cannot match.

The Engineering Behind Cordura's Toughness

To truly understand why Cordura outlasts other materials, we need to look at its core components individually. Each element plays a distinct and critical role in its overall performance.

The Foundation: High-Tenacity Fibers

The journey starts with fibers that are fundamentally stronger than their standard counterparts. These are specifically engineered nylon filaments designed to withstand significant pulling forces without breaking.

This high tensile strength forms the base level of Cordura's resistance to rips and tears.

The Key Differentiator: Air-Jet Texturing

This is arguably the most crucial step. During this process, jets of high-pressure air are used to tangle the flat nylon filaments, creating a bulkier, more substantial yarn.

This textured finish gives Cordura its characteristic matte appearance and slightly fuzzy feel. More importantly, it dramatically increases the fabric's ability to resist abrasion, as the tangled fibers dissipate friction more effectively than a smooth surface.

The Structure: A Dense Weave

Finally, these air-textured yarns are woven together in a very tight, often plain or basket weave pattern. This dense construction locks the durable fibers in place.

This structure prevents localized damage, like a snag or a scrape, from easily propagating into a larger tear.

How This Durability Compares in the Real World

The technical specifications translate into tangible performance advantages that have made Cordura a standard in demanding industries.

Benchmarking Against Other Fabrics

When tested, the performance gap between Cordura and other common materials becomes clear. It is demonstrably more durable:

- 2 times more durable than standard nylon

- 3 times more durable than standard polyester

- 10 times more durable than cotton duck fabric

Proven in Demanding Applications

This superior toughness is why Cordura is the material of choice for products where failure is not an option. It is used extensively in military gear, high-performance outdoor equipment, motorcycle apparel, and heavy-duty luggage.

Its ability to withstand constant dragging, scraping, and harsh environmental conditions ensures longevity and reliability.

Understanding the Trade-offs

No material is perfect for every application. Cordura's focus on extreme durability comes with inherent trade-offs that are important to consider.

Weight and Stiffness

The same texturing and dense weave that make Cordura tough also make it heavier and stiffer than standard nylon. For applications where minimizing weight is the absolute top priority, such as ultralight backpacking gear, other materials may be preferred.

Water Resistance

While Cordura can be coated with polyurethane (PU) or finished with a durable water repellent (DWR) to resist water, the underlying nylon fabric is not inherently waterproof. It will eventually absorb moisture if not properly treated.

Cost

The complex engineering and manufacturing processes behind Cordura mean it is a premium material. Its cost is higher than that of standard polyester or nylon fabrics.

Making the Right Choice for Your Gear

Understanding these principles allows you to select the right material based on your specific needs.

- If your primary focus is maximum abrasion and tear resistance: Cordura is the benchmark for gear that will face extreme and repeated abuse.

- If your primary focus is achieving the lightest possible weight: A standard or silicone-coated ripstop nylon will likely serve you better, though with a sacrifice in durability.

- If your primary focus is a balance of cost and casual performance: Standard polyester or nylon provides adequate durability for everyday items like school backpacks or light-use bags.

Ultimately, choosing a product made with Cordura is an investment in exceptional longevity and reliability.

Summary Table:

| Key Component | Role in Durability |

|---|---|

| High-Tenacity Fibers | Engineered nylon base for extreme tensile strength and tear resistance. |

| Air-Jet Texturing | Creates a bulky, fuzzy yarn that dramatically increases abrasion resistance. |

| Dense Weave | Locks fibers in place to prevent snags and scrapes from becoming large tears. |

Need Durable Footwear Built to Last?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial and tactical footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, integrating high-performance materials like Cordura for superior abrasion resistance and longevity.

Let's build tougher products together. Contact our team today to discuss your manufacturing needs and how we can deliver the reliability your customers demand.

Visual Guide

Related Products

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What is the role of extra-depth therapeutic shoes after flexor tenotomy? Optimize Recovery & Prevent Ulcers

- How does a biomechanical digital tracking system assist in reducing bone strain risks? Prevent Tactical Training Injuries

- What is the importance of a Risk Data Warehouse (RDW)? Transform Footwear Manufacturing with Predictive Risk Intelligence

- What is the fundamental role of blockchain technology in a decentralized footwear supply chain? Unlocking Global Trust

- Why should you try on shoes with the socks you plan to wear regularly? Ensure a Perfect, Pain-Free Fit

- What are the benefits of applying downsampling average processing to sensor signals? Boost Smart Footwear AI Accuracy

- What is the significance of the stitch or hand corded pattern in western boots? | A Guide to Craftsmanship & Style

- What are the common features of regular footwear? Defining Everyday Comfort & Style