I need to provide a definitive guide for intelligent professionals on chemical-resistant boots. It's not just about listing other PPE; it's about building a whole safety system.

My Goal: To empower with understanding, not just sell. My core strategy is to address both the surface need (what additional PPE?) and the deep need (why is a holistic system important?).

I know they're looking for practical answers. The surface answer is a mix of other PPE, safe work practices, and hazard awareness. But, I need to explain the why: why a comprehensive approach is necessary, considering the work environment, the specific chemicals involved, and other potential hazards.

To structure this, I'll start with a concise answer to their immediate question. Then, I will provide a framework for their understanding. I'll delve into hazard assessment, safe work practices, and comprehensive PPE. My core takeaway will be:

"Chemical resistant boots are the last line of defense; the primary goal is a safety system that minimizes contact with the hazard in the first place."

I'll break the article down like this:

- Beyond the Boot: Creating a System of Safety. I'll cover assessing the chemical hazard, implementing safe work practices, and integrating comprehensive PPE.

- Accounting for Co-Occurring Workplace Hazards. Chemical environments often have other risks like slips, impacts, and electrical hazards.

- Common Pitfalls to Avoid. I'll point out that "one-size-fits-all" doesn't work, that boots need inspection, and that training is crucial.

- Making the Right Choice for Your Goal. I'll give actionable advice based on specific scenarios, like known chemicals versus multi-hazard environments, and how to build a company-wide safety protocol.

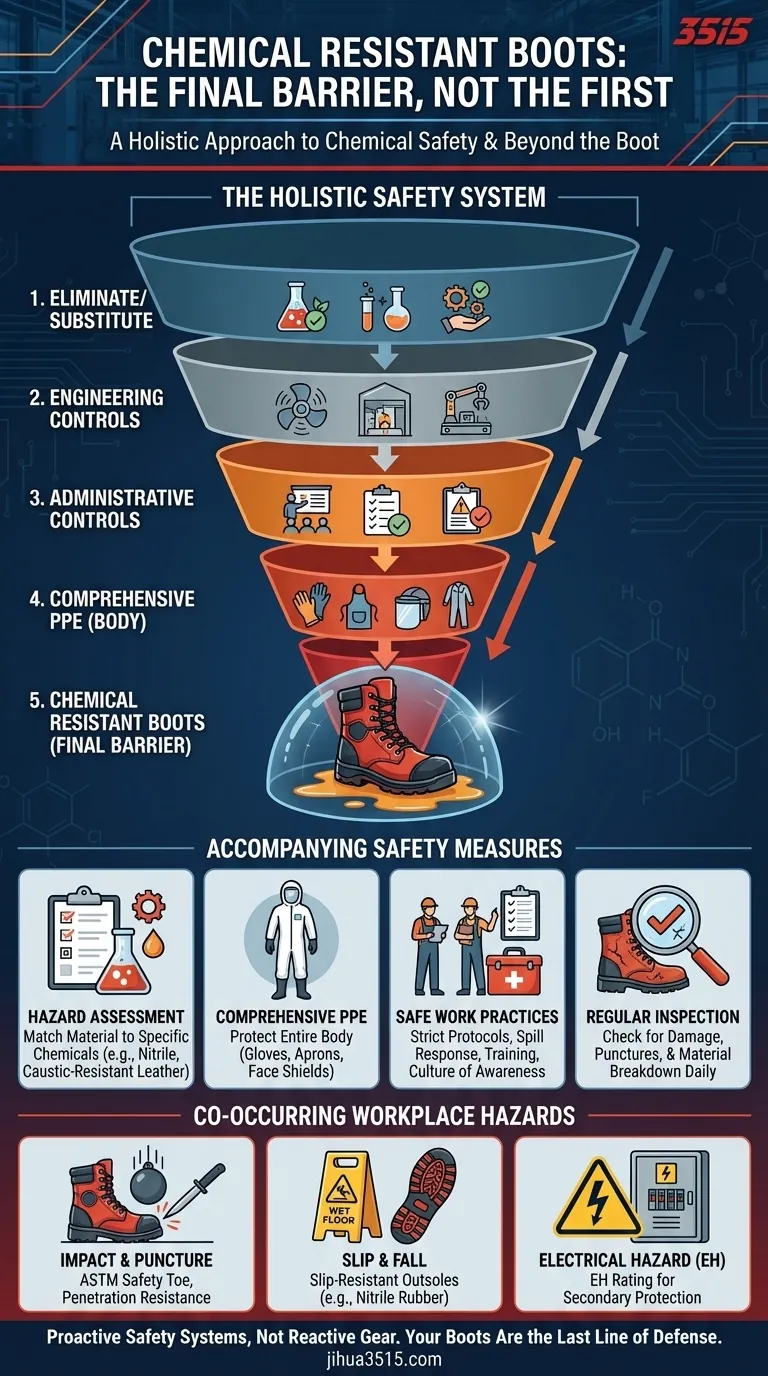

I'll keep paragraphs short and use bolding for key terms. This will make it easy to digest. I'll make sure to sound authoritative and objective. I'll end with a single, clear takeaway: proactive safety systems, not reactive gear, are the key to true protection. To be truly effective, chemical-resistant boots must be part of a comprehensive safety system. The necessary accompanying measures include using appropriate personal protective equipment (PPE) for the rest of the body, implementing strict safe work practices, conducting thorough hazard awareness training, and ensuring regular equipment inspection.

The boots are your last line of defense, not your first. True safety comes from a holistic system designed to minimize or eliminate chemical exposure in the first place, with the boots serving as a critical final barrier.

Beyond the Boot: Building a System of Safety

A chemical-resistant boot is a specialized tool. Its effectiveness depends entirely on the system in which it operates. Without proper context and support, even the best footwear offers a false sense of security.

Assess the Specific Chemical Hazard

Not all chemical-resistant boots are created equal. The material that resists a strong acid may not be effective against a particular solvent.

You must match the boot's protective material to the specific chemicals present. Common materials include Polyurethane and rubber Nitrile, which offer good protection against mild splashes.

For more aggressive substances like Sodium Hydroxide or Sulphuric Acid, look for specialized materials like caustic-resistant leather that have been tested against those specific hazards.

Implement Safe Work Practices

The most critical safety measure is a set of rigorous protocols designed to prevent accidents.

This includes clear procedures for handling and transporting chemicals, emergency response plans for spills, and a culture of constant hazard awareness.

Regular training is non-negotiable. Every team member must understand the risks and be proficient in all safety protocols.

Integrate Comprehensive PPE

Chemicals don't just target the feet. A splash that is stopped by a boot can still harm unprotected legs, hands, or eyes.

Your chemical safety plan must include an integrated suite of PPE, which could include gloves, aprons, coveralls, and eye/face protection, all rated for the specific chemical hazards present.

Accounting for Co-Occurring Workplace Hazards

A chemical hazard rarely exists in a vacuum. The work environment often presents multiple, simultaneous risks that your safety footwear must also address. According to OSHA, protective footwear is essential in any environment with these types of risks.

Impact and Puncture Resistance

Many industrial settings involve risks from heavy rolling objects or sharp items on the floor.

Your boots must also meet ASTM standards for impact and compression resistance (safety toe) or penetration resistance if these hazards are present.

Slip and Fall Protection

Chemical spills inherently create slippery surfaces.

Choose boots with high-traction, slip-resistant outsoles, such as those made from Nitrile rubber, to maintain stability on wet or contaminated floors.

Electrical Hazard (EH) Protection

If you work in an area with live electrical circuits, an accidental chemical spill could create a dangerous conductive path.

In these situations, footwear with an Electrical Hazard (EH) rating is essential to provide a secondary source of protection from electrocution.

Common Pitfalls to Avoid

Simply mandating "chemical-resistant boots" is not enough. Several common oversights can undermine your entire safety program.

Overlooking Proper Fit and Comfort

Footwear that is uncomfortable or fits poorly can lead to blisters, cracked feet, or fatigue, especially in wet conditions as noted for landscapers.

This discomfort distracts workers, making them less focused and more prone to accidents. It also discourages proper use.

Neglecting Inspection and Maintenance

Chemical-resistant materials degrade over time, especially with exposure to harsh substances and UV light.

Boots must be regularly inspected for cracks, punctures, or signs of material breakdown. A compromised boot provides zero protection.

Creating a False Sense of Security

Never let PPE become a substitute for cautious behavior. The presence of safety gear can sometimes lead to riskier actions.

Reinforce that PPE is the final barrier and that adherence to safe work practices is the primary method of ensuring safety.

Making the Right Choice for Your Goal

Select your safety measures based on a clear understanding of your specific operational environment and primary risks.

- If your primary focus is handling specific, aggressive chemicals: Prioritize boots made of materials explicitly tested and rated for those substances and supplement with full-body PPE.

- If your primary focus is a multi-hazard industrial environment: Select boots with multiple certifications (e.g., chemical resistance, safety toe, EH rating) to cover all potential risks.

- If your primary focus is establishing a comprehensive safety program: Begin with hazard assessment and safe work protocols, then select the full range of PPE as a system to mitigate the identified risks.

Ultimately, protective footwear is just one component of a proactive safety culture that protects your team from all angles.

Summary Table:

| Key Safety Measure | Purpose | Examples |

|---|---|---|

| Comprehensive PPE | Protect entire body from splashes | Gloves, aprons, face shields |

| Safe Work Practices | Prevent chemical exposure incidents | Spill procedures, handling protocols |

| Hazard Assessment | Match protection to specific risks | Chemical compatibility, co-occurring hazards |

| Regular Inspection | Ensure gear integrity and effectiveness | Check for cracks, degradation |

Need a reliable partner for your chemical safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of chemical-resistant footwear, designed to meet rigorous safety standards and integrate seamlessly into your holistic safety program.

Contact us today to discuss your specific needs and ensure your team has the reliable, high-quality protection they deserve.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- Why are safety boots with steel toes mandatory for logging? Ultimate Protection Against Heavy Impact Hazards

- What are heavy duty work boots designed for? Maximum Protection for Hazardous Work Environments

- What are the primary protective roles of safety shoes for mosquito control? Safeguard Workers from Chemical & Field Risks

- What boots do they wear on oil rigs? Essential Safety Footwear for Harsh Conditions

- What is a safety-toe in a boot? Your Guide to Choosing the Right Protection