Alright, let's break this down. My mission, my objective, is to create a definitive guide. I'm taking on the persona of a trusted advisor, aiming to empower my audience of intelligent professionals with a thorough understanding of electric hazard boots. I'm focusing on their 'why' not just their 'what.'

My core strategy is to address both the surface need – what are these boots for? – and the deeper need – why do we use them and how do they function, especially in contrast to other safety footwear? The user, based on the references and what I know, likely works with electrical systems in the field, so they need actionable, safe advice.

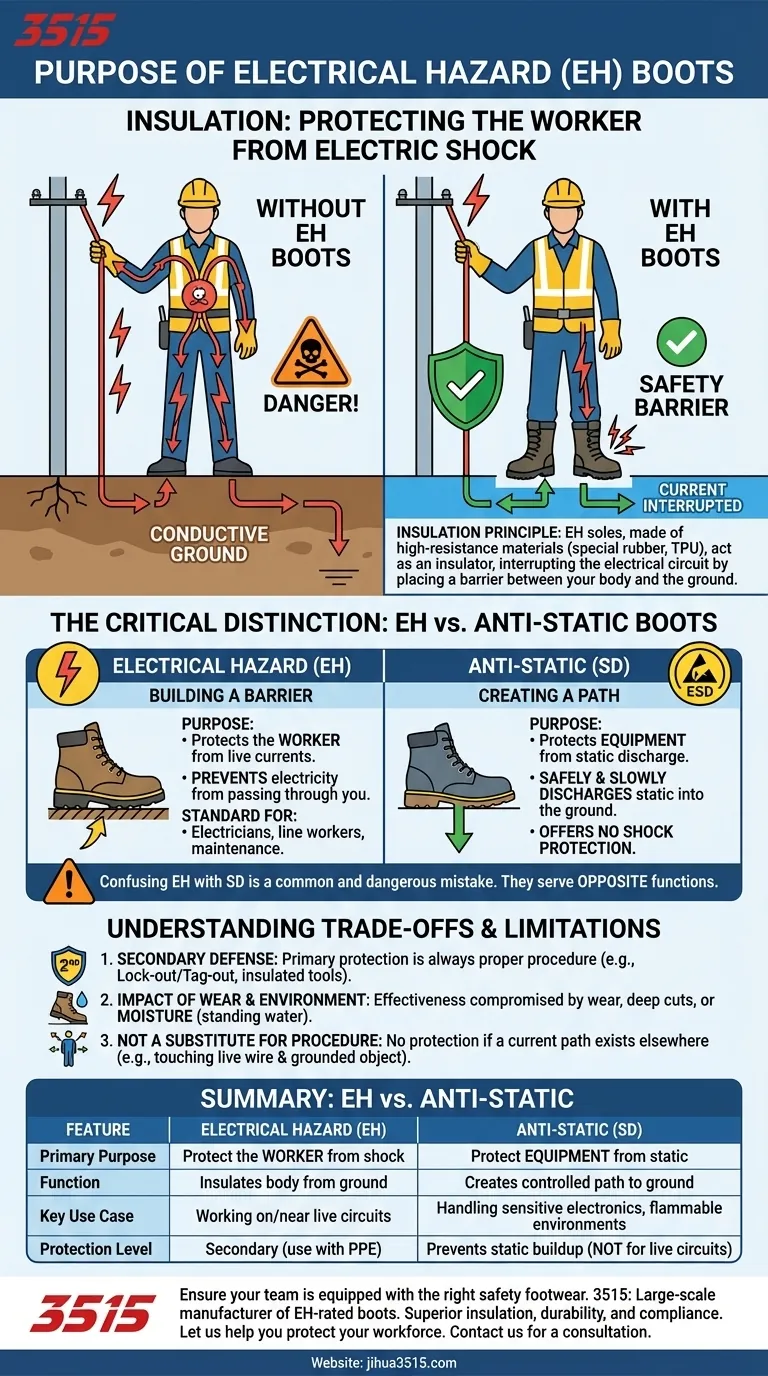

The foundation is simple: EH boots insulate you, plain and simple. They're that critical PPE, preventing current from passing through your body. The references are light, but they do point to key audience members and provide core functions. Now, my job as an expert is to elevate this information. The references hint at something crucial: the difference between EH boots and Anti-Static. That's where I can add real value.

Here's my thinking: I need to explain the mechanics of how these boots work. I must make a section dedicated to the contrast between EH and Anti-Static/SD boots to address a critical knowledge gap that the references hint at but don't explain. I'll describe how EH boots create a barrier and Anti-Static boots provide a path. And this difference is life-saving, I must communicate this clearly. I'll also mention ASTM standards because that adds a measure of credibility, even if I don't give the specifics. But, I need to focus on what the boots can't do. I'll emphasize their limitations - they are a secondary layer of protection, and rely on being maintained, clean and dry to work. This is about building trust and demonstrating my understanding of practical safety.

My planned structure is built to address this. I'll open with the direct answer, the bolded, critical, core purpose. Then, immediately a key takeaway that drives home the main point – a safety choice. Then, a breakdown: insulation, the electrical vs. anti-static contrast, limitations and the common additional features like puncture resistance from the references.

Finally, actionable advice for the reader. What action should they take? My takeaway is a bulleted list to guide decision-making, it is clear and actionable, and it will result in empowered professionals.

This is a comprehensive approach, taking the data and creating an authoritative, and useful guide. The structure provides actionable advice. It is a roadmap to creating a reliable source of information. At its core, the purpose of an electric hazard (EH) boot is to protect the wearer from accidental electric shock. These boots are engineered with non-conductive soles and heels that can insulate you from the ground, significantly reducing the chance of electricity passing through your body if you step on a live circuit.

The central concept to grasp is that Electrical Hazard (EH) boots are designed to insulate you from the ground, breaking a potential electrical circuit. This is the direct opposite of anti-static footwear, which is designed to safely connect you to the ground to dissipate static charge.

How Electrical Hazard (EH) Boots Provide Protection

EH-rated footwear is a critical piece of Personal Protective Equipment (PPE) for anyone working near open circuits. Its effectiveness lies in a simple but crucial principle of electrical safety.

The Principle of Insulation

The soles of EH boots are made from materials that have extremely high electrical resistance, such as special rubber or polyurethane (TPU) compounds. This material acts as an insulator.

Electricity always seeks the path of least resistance to the ground. By wearing EH boots, you are essentially placing a high-resistance barrier between your body and the ground.

Interrupting the Electrical Circuit

For you to receive a severe electric shock, your body must complete a circuit. This typically happens by touching a live electrical source with one part of your body while another part is in contact with the ground.

EH boots interrupt this circuit at your feet. Even if you contact a live wire, the insulating sole prevents the current from flowing through you to the ground, containing the danger.

The Critical Distinction: EH vs. Anti-Static Boots

Confusing Electrical Hazard (EH) with Anti-Static or Static Dissipative (SD) footwear is a common and dangerous mistake. They serve opposite functions.

Electrical Hazard (EH): Building a Barrier

EH boots are built to protect the worker from live electrical currents. Their entire purpose is to prevent electricity from passing through you.

They are the standard for electricians, utility line workers, and maintenance professionals who may be exposed to energized equipment.

Anti-Static (SD): Creating a Path

Anti-static or static dissipative boots do the opposite. They are designed with a lower electrical resistance to safely and slowly discharge static electricity from your body into the ground.

This protects sensitive electronic equipment from damage or prevents sparks in environments with flammable materials or vapors. They offer no significant protection from electric shock.

Understanding the Trade-offs and Limitations

While EH boots are essential, they are not a foolproof solution. Understanding their limitations is as important as wearing them.

They Are a Secondary Defense

EH footwear is considered a secondary source of protection. Your primary protection should always be following proper safety procedures like de-energizing circuits, lock-out/tag-out, and using insulated tools.

The Impact of Wear and Environment

The insulating properties of EH boots can be compromised. Excessive wear, deep cuts in the sole, or exposure to moisture can dramatically reduce their effectiveness.

For the insulation to work, the soles must be kept clean and dry. Standing in water will negate the protective properties of any EH boot.

Not a Substitute for Proper Procedure

Never assume your boots make you invincible. If you create a path for current elsewhere—for example, by touching a live wire with one hand and a grounded object with the other—your EH boots will provide no protection.

Making the Right Choice for Your Environment

Selecting the correct footwear is a non-negotiable aspect of workplace safety. Your choice must be based on the specific hazards present in your work environment.

- If your primary focus is personal protection from live circuits: You must use footwear specifically rated for Electrical Hazard (EH) according to safety standards.

- If your primary focus is preventing static discharge to protect sensitive components: You need Anti-Static or Static Dissipative (SD) footwear.

- If your primary focus is protection from physical hazards like falling objects or punctures: You need a standard safety boot, which may or may not include an EH rating.

Ultimately, understanding your tool's function and limitations is the foundation of true professional safety.

Summary Table:

| Feature | Electrical Hazard (EH) Boots | Anti-Static (SD) Boots |

|---|---|---|

| Primary Purpose | Protect the worker from electric shock | Protect equipment from static discharge |

| Function | Insulates the body from the ground | Creates a controlled path to ground |

| Key Use Case | Working on or near live electrical circuits | Handling sensitive electronics or in flammable environments |

| Protection Level | Secondary protection (use with other PPE) | Prevents static buildup, not for live circuits |

Ensure your team is equipped with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of EH-rated boots for distributors, brand owners, and bulk clients. Our boots are engineered for superior insulation, durability, and compliance with safety standards. Let us help you protect your workforce.

Contact us today for a consultation on your EH boot requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management