The key to waterproofing your boots is to match the treatment method directly to the material of the upper. Applying the wrong product is not only ineffective but can permanently damage your footwear. Smooth leather requires penetrating waxes or creams to condition and seal its pores, while delicate materials like suede, nubuck, and synthetic fabrics need a surface-level spray that won't alter their texture.

The effectiveness of any waterproofing treatment hinges on two principles: starting with a perfectly clean boot and choosing a product specifically designed for its material. Waxes saturate leather for deep protection, while specialized sprays create a breathable barrier on delicate suede and synthetic fabrics.

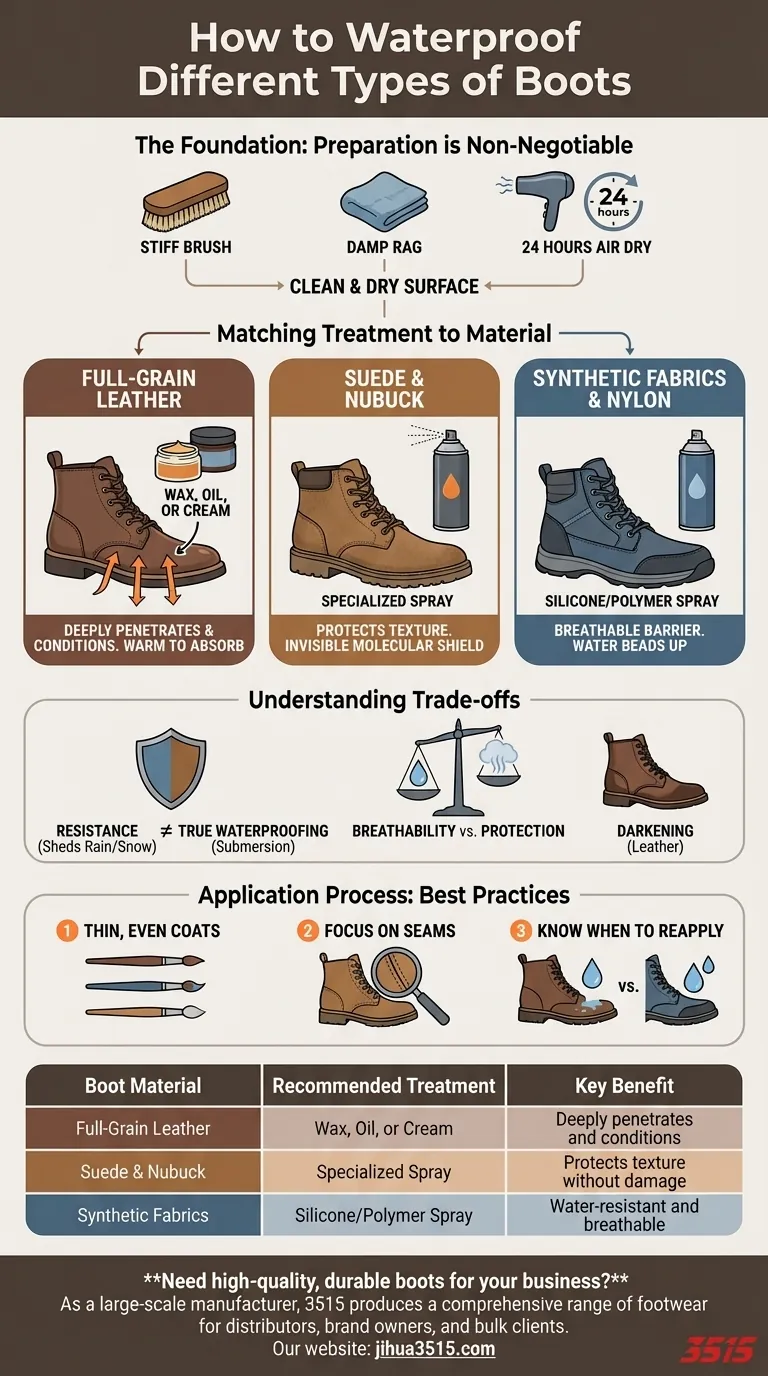

The Foundation: Preparation is Non-Negotiable

Before you apply any product, you must start with a clean, dry surface. Attempting to waterproof a dirty boot will trap grime and prevent the sealant from properly bonding to the material.

Why Cleaning is Critical

Dirt, dust, and mud clog the pores of leather and the weave of fabrics. This creates a physical barrier that blocks waterproofing agents, leading to a weak, patchy seal that will fail quickly.

The Cleaning Process

First, use a stiff brush to remove all loose dirt and debris. For stubborn spots, use a damp rag. For leather, you may use a specialized leather cleaner, but always let the boots air dry completely—for at least 24 hours—before proceeding.

Matching the Treatment to the Material

The composition of your boot's upper dictates the correct waterproofing method. There is no one-size-fits-all solution.

Full-Grain Leather: Creams and Waxes

Smooth leather boots benefit from treatments that penetrate and saturate the material. Waxes, oils, and creams (often containing beeswax or mink oil) are ideal.

These products work by filling the microscopic pores in the leather, creating a robust barrier against moisture. For best results, gently warm the leather with a hairdryer on a low setting before application to help it absorb the wax more deeply.

Suede & Nubuck: The Delicate Approach

These materials have a soft, napped texture that will be ruined by heavy waxes or creams. For suede and nubuck, you must only use a specialized waterproof spray.

These sprays create an invisible molecular shield over the fibers without matting them down or causing discoloration. Always test the spray on a small, inconspicuous area first.

Synthetic Fabrics & Nylon: The Power of Sprays

Modern hiking and tactical boots often use uppers made of nylon, polyester, or other synthetic fabrics. These materials do not absorb waxes like leather.

The best solution is a silicone or polymer-based waterproofing spray. These products coat the exterior of the fabric weave, causing water to bead up and roll off without compromising the material's inherent breathability.

Understanding the Trade-offs

Waterproofing is not an absolute state; it involves balancing protection with other material properties.

Water Resistance vs. True Waterproofing

Treating your boots significantly enhances their water resistance, meaning they will shed rain, snow, and splashes. However, this does not make them truly waterproof like a seamless rubber boot.

If your goal is to stand in deep water for extended periods, no topical treatment on a leather or fabric boot can replace the performance of a rubber boot or one with an integrated waterproof membrane (like Gore-Tex).

The Breathability Factor

A key trade-off is protection versus breathability. Heavy wax applications on leather create a formidable barrier to water, but they can also reduce the leather's ability to breathe, potentially leading to sweatier feet.

Sprays, particularly those designed for synthetic fabrics, are generally better at maintaining breathability while still providing excellent water repellency.

Potential for Darkening

Be aware that most waxes, oils, and creams will noticeably darken the color of leather. This is a normal part of the conditioning process. Sprays typically have a minimal effect on color.

The Application Process: Best Practices

How you apply the product is just as important as which one you choose.

Apply Thin, Even Coats

It is always better to apply two or three thin, even coats than one thick, messy layer. This allows for better absorption and a more consistent seal. Let each coat dry before applying the next.

Focus on the Seams

The seams and welting (where the upper connects to the sole) are the most common failure points for water entry. Pay extra attention to these areas, ensuring they are fully saturated with your chosen sealant.

Know When to Reapply

Your boots will tell you when they need another treatment. When you notice that water is starting to darken the surface and soak in rather than beading up and rolling off, it's time to clean them and reapply. Depending on use, this could be every few weeks or every few months.

Making the Right Choice for Your Boots

To select the best approach, consider your boot type and how you use them.

- If you have full-grain leather work boots: Opt for a heavy-duty wax or oil-based sealant for maximum durability and water repellency.

- If you have suede or nubuck fashion boots: Use only a specialized waterproof spray to protect the delicate texture without causing stains or damage.

- If you have synthetic fabric hiking boots: Choose a modern silicone or polymer-based spray that provides excellent water resistance while preserving breathability.

- If you need guaranteed waterproofing for submersion: Recognize the limitations of treatments and choose a boot made from rubber or with an integrated waterproof membrane.

A properly chosen and applied treatment protects your investment and ensures your feet remain dry, comfortable, and ready for any condition.

Summary Table:

| Boot Material | Recommended Treatment | Key Benefit |

|---|---|---|

| Full-Grain Leather | Wax, Oil, or Cream | Deeply penetrates and conditions |

| Suede & Nubuck | Specialized Spray | Protects texture without damage |

| Synthetic Fabrics | Silicone/Polymer Spray | Water-resistant and breathable |

Need high-quality, durable boots for your business? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the right product for your market. Contact us today to discuss your custom footwear needs and benefit from our expert manufacturing solutions.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

People Also Ask

- Are military camouflage boots waterproof? How to Choose Boots That Keep Feet Dry

- Why is waterproofing important for tactical boots? Protect Your Feet and Gear in Any Mission

- What are the key features of the new Army Jungle Combat Boot? A Breakdown for Hot & Wet Environments

- Why is waterproofing important in tactical boots? Essential for Foot Health & Mission Success

- How do military camouflage boots protect against adverse weather? Ensuring Dry, Warm Feet in Any Condition