Proper work boot lace maintenance goes beyond simply tying them correctly. It is a simple, three-part process of routine cleaning, regular inspection for wear and tear, and ensuring they are always tied securely. This small effort is critical for maintaining the structural integrity of your boots, ensuring your safety, and maximizing their lifespan.

Neglecting your boot laces is neglecting your boots. They are not just fasteners; they are a critical component of the boot's support system, and their condition directly impacts your safety, comfort, and the longevity of your footwear.

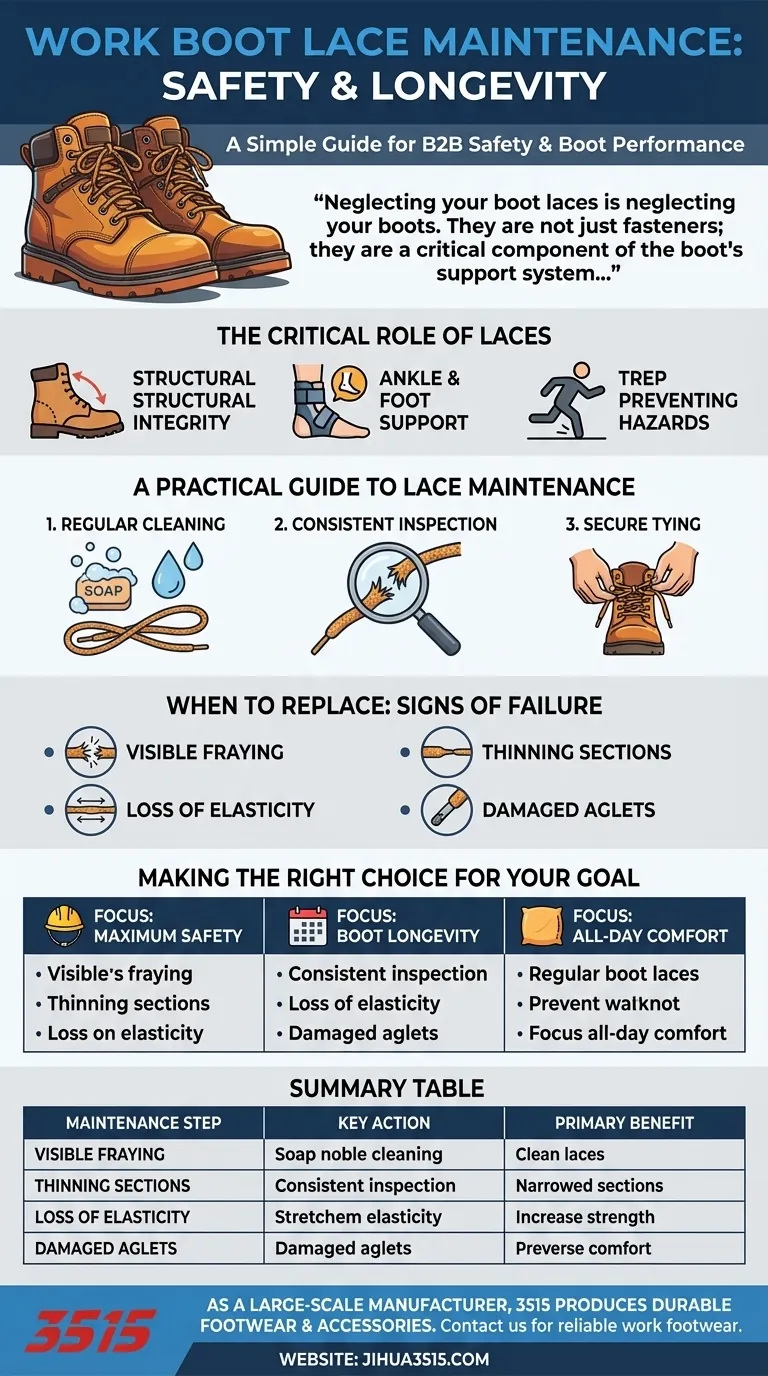

The Critical Role of Laces in Boot Performance

Properly maintained laces are fundamental to how your work boots function. They are the primary mechanism for securing the boot to your foot, which has direct implications for both safety and the boot's structure.

Maintaining Structural Integrity

When laces are left untied or are not properly tensioned, the boot is allowed to flex in ways it was not designed to. This distorts the boot's shape over time, particularly around the ankle collar and eyelets.

This distortion accelerates the breakdown of supportive materials, leading to premature wear and tear on the entire boot.

Ensuring Ankle and Foot Support

The key function of a work boot is to keep your feet and ankles in the correct, stable position. Laces provide the adjustable tension needed to lock your heel in place and support your ankle.

Worn, stretched, or improperly tied laces fail to provide this necessary support, increasing the risk of sprains and instability on uneven surfaces.

Preventing Workplace Hazards

The most obvious danger is a loose or untied lace creating a trip hazard. Less obvious is the risk of a weakened lace snapping under strain, causing the boot to become completely loose at a critical moment.

A Practical Guide to Lace Maintenance

Integrating lace care into your regular boot cleaning routine is simple and effective. Think of it as a quick system check.

Step 1: Regular Cleaning

Laces accumulate dirt, grime, and oils just like the rest of the boot. This grit can act as an abrasive, slowly breaking down the lace fibers.

When you clean your boots, remove the laces and wash them separately in a small container with mild soap and water. Allow them to air dry completely before re-lacing.

Step 2: Consistent Inspection

Every time you lace up, perform a quick visual and tactile inspection. This is the most important step in preventing failure.

Look for signs of fraying, thinning, or sections that feel softer or weaker than the rest. Pay close attention to the areas that pass through the eyelets, as this is where most friction occurs. Also, check that the aglets (the plastic or metal tips) are intact.

Understanding the Trade-offs: When to Replace

Knowing when to replace your laces is not about saving a few dollars; it's about preventing failure. There is no real trade-off—a worn lace is a liability.

The Dangers of a Failing Lace

A lace that snaps on the job can immediately render your boot unsafe and unsupportive. The cost of a new pair of high-quality laces is insignificant compared to the risk of an injury or the damage done to a boot from being worn improperly.

Signs That Demand Immediate Replacement

Do not wait for a lace to break. Replace both laces immediately if you notice:

- Visible Fraying: Any area where the weave is coming apart.

- Thinning: Sections that are noticeably narrower from friction.

- Loss of Elasticity: If the lace feels overly stretched and no longer holds tension.

- Damaged Aglets: A missing aglet makes lacing difficult and can cause the end to unravel quickly.

Making the Right Choice for Your Goal

Your maintenance routine should align with your primary needs on the job site.

- If your primary focus is maximum safety: Inspect your laces daily for any sign of wear and replace them immediately at the first hint of fraying or thinning.

- If your primary focus is boot longevity: Ensure your laces are always tied securely to prevent boot shape distortion and premature wear.

- If your primary focus is all-day comfort: Pay attention to lacing techniques that provide even pressure across your foot, and replace stretched-out laces that no longer hold consistent tension.

Ultimately, treating your boot laces as essential equipment is the key to getting the most safety and value out of your work boots.

Summary Table:

| Maintenance Step | Key Action | Primary Benefit |

|---|---|---|

| Regular Cleaning | Wash with mild soap and water | Removes abrasive grit, prevents fiber breakdown |

| Consistent Inspection | Check for fraying, thinning, damaged aglets | Prevents unexpected lace failure on the job |

| Secure Tying | Ensure proper tension and knot integrity | Maintains ankle support and boot structural shape |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear and accessories for distributors, brand owners, and bulk clients. Don't let worn-out laces compromise your safety or your boots' longevity. Our production capabilities encompass all types of industrial shoes and boots, built to withstand the toughest conditions. Contact us today to explore our range of reliable work footwear and ensure your team is equipped for safety and performance.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety