To choose the right safety boots, you must first perform a hazard assessment of your workplace. Boots with steel or composite toes protect against impact from falling objects, Electrical Hazard (EH) rated boots insulate against shock, slip-resistant outsoles provide traction on wet or oily surfaces, and waterproof materials are essential for wet conditions.

The goal is not to find a single "best" boot, but to precisely match the certified protective features of the footwear to the specific, identified risks of your work environment. An incorrect choice can create a false sense of security, which is often more dangerous than no protection at all.

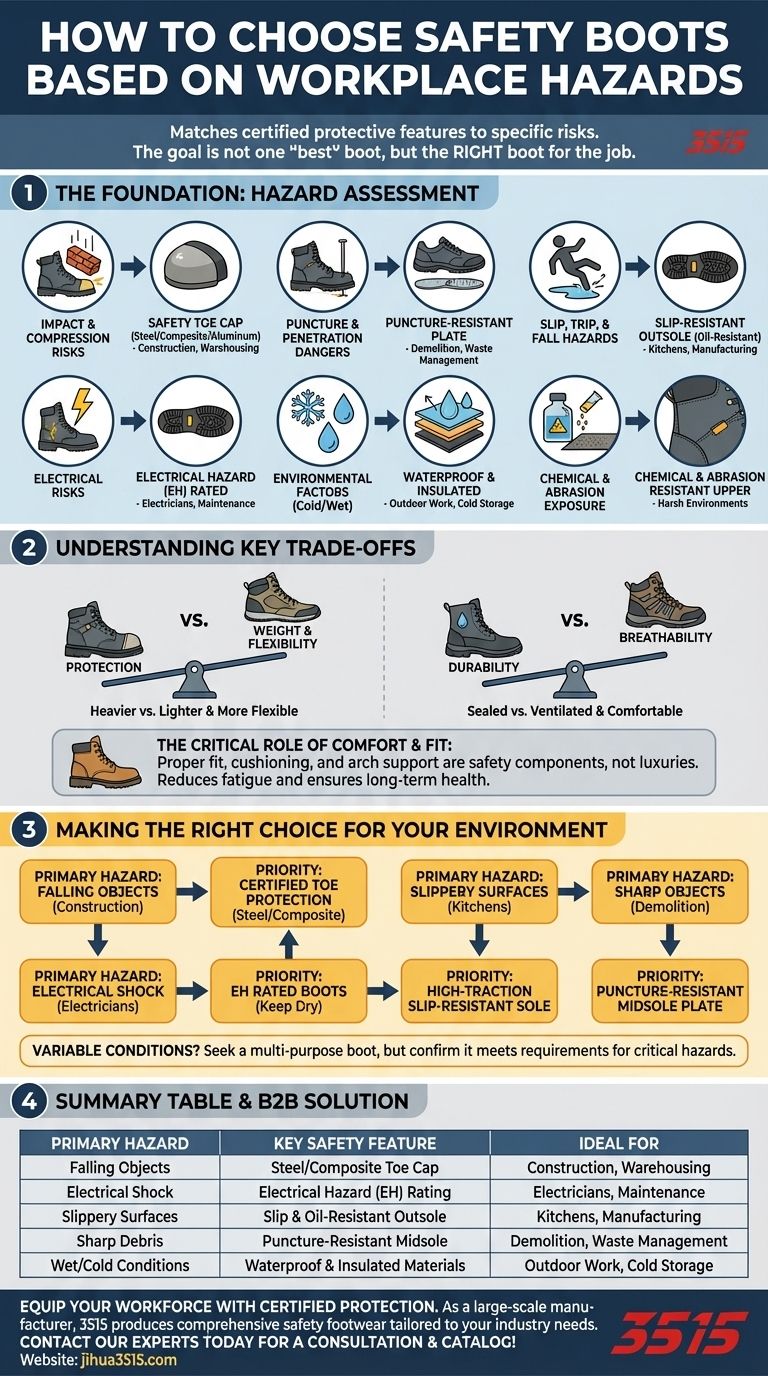

The Foundation: A Workplace Hazard Assessment

Before you can select the right footwear, you must systematically identify the potential dangers you will face. Each feature of a safety boot is engineered to neutralize a specific type of risk.

Identifying Impact and Compression Risks

This is the most common reason for safety footwear. Heavy industries, construction sites, and warehouses present constant risks from falling objects or rolling equipment.

Your primary defense is the safety toe cap. These come in three main materials: steel, aluminum, and composite. All must meet the same safety standards for impact and compression, but they have different properties.

Assessing Puncture and Penetration Dangers

Workplaces like demolition sites, waste management facilities, and construction zones often have sharp debris underfoot, such as nails, screws, and metal shards.

Look for boots with a puncture-resistant plate built into the midsole. This is a critical feature that protects the sole of your foot from being pierced.

Evaluating Slip, Trip, and Fall Hazards

Slips are one of the most frequent causes of workplace injuries. The risk is elevated on surfaces contaminated with water, oil, chemicals, or other liquids.

The key feature here is a slip-resistant outsole. Pay close attention to the tread pattern and the material of the sole. Boots may also be specifically rated as oil-resistant for environments with petrochemicals.

Understanding Electrical Risks

For anyone working near live circuits or high-voltage equipment, such as electricians or certain maintenance professionals, footwear is a critical line of defense.

You must select boots specifically rated for Electrical Hazard (EH). These are designed with non-conductive soles and heels to insulate you from the ground, reducing the chance of electrocution.

Considering Environmental Factors

Your work environment itself can be a hazard. Extreme temperatures and moisture not only cause discomfort but can lead to health issues and accidents.

For cold or wet climates, waterproof and insulated boots are essential. Waterproofing keeps feet dry to prevent blisters and fungal infections, while insulation helps prevent frostbite and maintain comfort.

Recognizing Chemical and Abrasion Exposure

Some jobs involve contact with corrosive substances like acids or require working on harsh, abrasive surfaces.

The boot's upper material is critical here. Look for materials known for their chemical resistance and high abrasion resistance to ensure the boot maintains its structural integrity over time.

Understanding the Key Trade-offs

Choosing the perfect safety boot always involves balancing competing priorities. Understanding these trade-offs is essential for making a practical and effective decision.

Protection vs. Weight and Flexibility

Maximum protection often comes at a cost. Steel toes offer excellent protection but are the heaviest option, which can contribute to fatigue over a long shift.

Composite toes are much lighter and don't conduct temperature, but they can be bulkier than steel to achieve the same safety rating. A heavily armored boot may also be less flexible, restricting natural movement.

Durability vs. Breathability

A fully sealed, waterproof boot is excellent for keeping moisture out, but it can also trap sweat and heat inside. This can lead to significant discomfort in hot and humid conditions.

For warmer environments, look for boots made with breathable materials that still offer the necessary protection. There is a constant engineering balance between creating a barrier and allowing for ventilation.

The Critical Role of Comfort and Fit

An uncomfortable boot is a dangerous boot. If footwear causes pain, blisters, or excessive fatigue, it may be worn improperly or avoided altogether, defeating its purpose.

Proper fit, cushioning, and arch support are not luxuries; they are crucial safety components. They ensure you can focus on your work without distraction and reduce the long-term physical strain on your feet, ankles, and back.

Making the Right Choice for Your Environment

Your final decision should be a direct response to your workplace's primary risks.

- If your primary hazard is falling objects (Construction, Warehousing): Prioritize certified toe protection (steel or composite) and consider metatarsal guards for heavy-duty roles.

- If your primary hazard is electrical shock (Electricians, Maintenance): Insist on Electrical Hazard (EH) rated boots and ensure they are kept dry and in good condition.

- If your primary hazard is slippery surfaces (Kitchens, Manufacturing): Focus on boots with a high-traction, certified slip-resistant (and oil-resistant, if applicable) sole.

- If your primary hazard is sharp objects underfoot (Demolition, Waste Management): Select boots with a built-in, certified puncture-resistant plate in the midsole.

- If you work in highly variable conditions: Seek a multi-purpose boot, but always confirm it meets the minimum safety requirements for your most critical and frequent hazards.

A methodical assessment of your environment is the only way to ensure your safety footwear is a genuine asset, not just a requirement.

Summary Table:

| Primary Hazard | Key Safety Feature | Ideal For |

|---|---|---|

| Falling Objects | Steel/Composite Toe Cap | Construction, Warehousing |

| Electrical Shock | Electrical Hazard (EH) Rating | Electricians, Maintenance |

| Slippery Surfaces | Slip & Oil-Resistant Outsole | Kitchens, Manufacturing |

| Sharp Debris | Puncture-Resistant Midsole | Demolition, Waste Management |

| Wet/Cold Conditions | Waterproof & Insulated Materials | Outdoor Work, Cold Storage |

Ensure your workforce is equipped with the right protection. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work shoes, precisely engineered to meet the specific hazards of your industry. Get durable, compliant, and comfortable footwear solutions tailored to your needs. Contact our experts today for a consultation and catalog!

Visual Guide

Related Products

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What is the function of rubber outsoles on safety shoes? Expert Insights on Slip Prevention and Industrial Traction

- Why are high-performance industrial safety shoes necessary in palm oil processing? Protect Workers from Oil & Heat

- What quality control measures are taken in safety shoes manufacturing? Ensure Maximum Protection & Compliance

- What are the common types of upper materials for labour protection shoes? Choose the Right Material for Your Work Environment

- How do forestry protective equipment influence energy consumption? Real-World Impacts on Worker Labor Intensity

- Why is the use of professional safety shoes with chemical resistance essential during Mixed Bed Polisher regeneration?

- What is the significance of Blockchain (BT) for raw material traceability in a sustainable safety shoe supply chain?

- What are the advantages of composite-toed shoes? Lighter, Safer, and More Comfortable