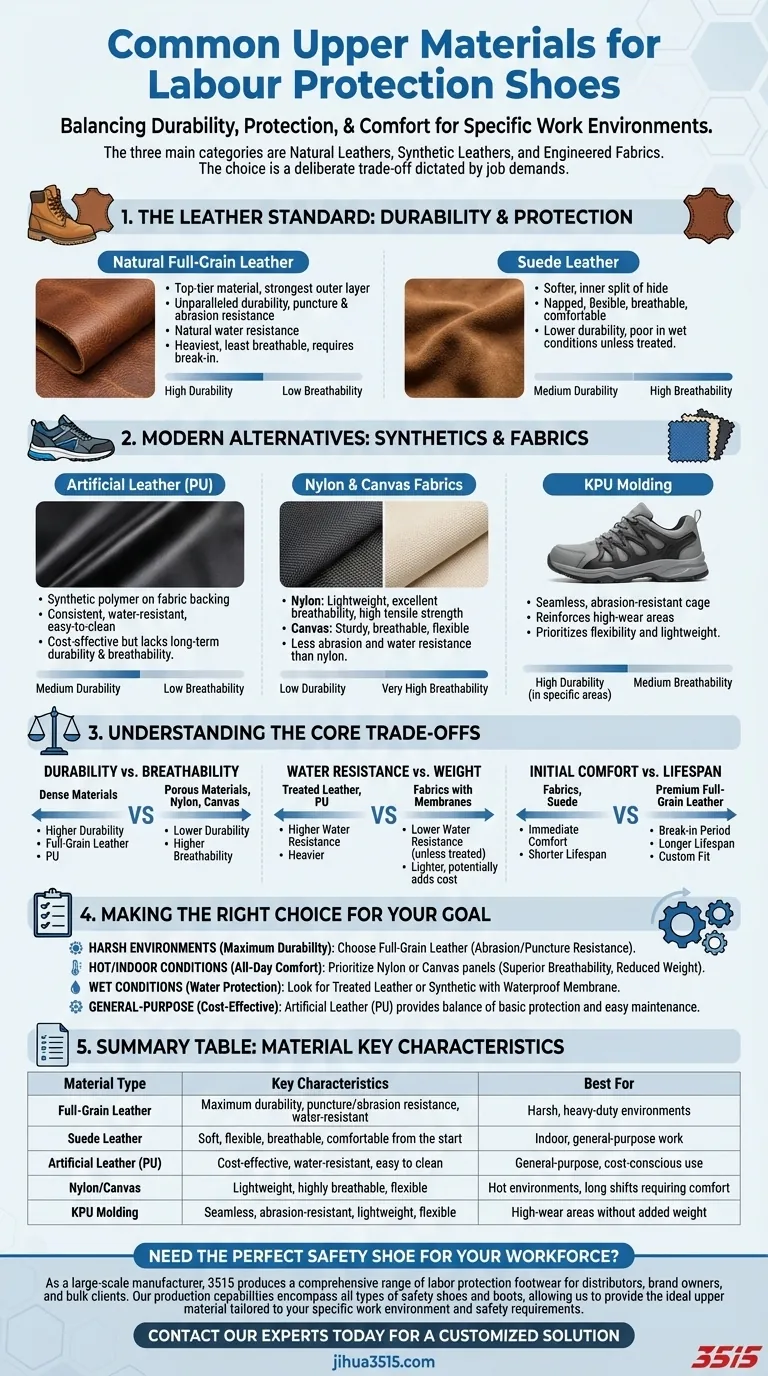

The most common upper materials for labor protection shoes fall into three main categories: natural leathers, synthetic leathers, and engineered fabrics. These materials, which include full-grain leather, suede, artificial leather (PU), nylon, and canvas, are chosen to balance durability, protection, and wearer comfort for specific work environments.

The ideal upper material for a safety shoe is not a one-size-fits-all answer. The choice represents a deliberate trade-off between rugged durability, environmental resistance, and lightweight breathability, dictated entirely by the demands of the job.

The Leather Standard: Durability and Protection

Leather has long been the benchmark for high-performance work footwear due to its exceptional strength and ability to mold to the wearer's foot over time.

Natural Full-Grain Leather

Full-grain leather is the top-tier material, using the strongest outer layer of the animal hide. It offers unparalleled durability, puncture resistance, and abrasion resistance.

Its dense fiber structure also provides natural water resistance. However, it is typically the heaviest and least breathable option, often requiring a break-in period.

Suede Leather

Suede is created from the softer, inner split of the hide. This gives it a napped, flexible finish that is more breathable and comfortable than full-grain leather from the start.

The trade-off is significantly lower durability and poor performance in wet conditions unless specifically treated.

Modern Alternatives: Synthetics and Fabrics

Engineered materials were developed to offer specific performance characteristics that leather cannot, such as light weight, immediate flexibility, and enhanced breathability.

Artificial Leather (PU)

Polyurethane (PU) leather is a synthetic polymer coated onto a fabric backing. It provides a consistent, water-resistant, and easy-to-clean surface.

It is a cost-effective alternative to natural leather but lacks its long-term durability and breathability, sometimes leading to sweaty feet during long shifts.

Nylon and Canvas Fabrics

Nylon is a synthetic fabric prized for its light weight, excellent breathability, and high tensile strength. It is often used in panels on hiking-style safety shoes to reduce weight and increase comfort in hot environments.

Canvas, a sturdy cotton fabric, offers similar benefits in breathability and flexibility but provides less abrasion and water resistance than nylon.

KPU Molding

Knitted Polyurethane (KPU) is a modern material that can be directly molded onto a fabric upper. This process creates a seamless, highly abrasion-resistant cage for protection without the stitches and seams that can fail.

It is frequently used to reinforce high-wear areas on shoes that prioritize flexibility and light weight.

Understanding the Core Trade-offs

Choosing an upper material always involves balancing competing factors. Understanding these compromises is key to selecting the right footwear.

Durability vs. Breathability

The most fundamental trade-off. Dense materials like full-grain leather offer maximum durability but trap heat and moisture. Porous materials like nylon and canvas offer maximum breathability but are more susceptible to cuts and abrasion.

Water Resistance vs. Weight

Materials that repel water effectively, like treated leather or PU, are often heavier and less breathable. Lightweight fabrics require special membranes or coatings to achieve water resistance, which can add cost.

Initial Comfort vs. Lifespan

Fabrics and suedes offer immediate, out-of-the-box comfort and flexibility. In contrast, premium full-grain leather requires a break-in period but will ultimately last longer and provide a custom-molded fit.

Making the Right Choice for Your Goal

Your work environment and daily tasks should be the deciding factor.

- If your primary focus is maximum durability in harsh environments: Choose full-grain leather for its unmatched resistance to abrasion and punctures.

- If your primary focus is all-day comfort in hot or indoor conditions: Prioritize shoes with large nylon or canvas panels for superior breathability and reduced weight.

- If your primary focus is working in wet conditions: Look for treated leather or a synthetic upper combined with a certified waterproof membrane.

- If your primary focus is a cost-effective, general-purpose shoe: Artificial leather (PU) provides a solid balance of basic protection and easy maintenance.

Understanding these materials transforms your safety shoe from a simple requirement into a specialized tool for the job.

Summary Table:

| Material Type | Key Characteristics | Best For |

|---|---|---|

| Full-Grain Leather | Maximum durability, puncture/abrasion resistance, water-resistant | Harsh, heavy-duty environments |

| Suede Leather | Soft, flexible, breathable, comfortable from the start | Indoor, general-purpose work |

| Artificial Leather (PU) | Cost-effective, water-resistant, easy to clean | General-purpose, cost-conscious use |

| Nylon/Canvas | Lightweight, highly breathable, flexible | Hot environments, long shifts requiring comfort |

| KPU Molding | Seamless, abrasion-resistant, lightweight, flexible | High-wear areas without added weight |

Need the Perfect Safety Shoe for Your Workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of labor protection footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, allowing us to provide the ideal upper material—whether full-grain leather for maximum durability or breathable nylon for comfort—tailored to your specific work environment and safety requirements.

Contact our experts today for a customized solution that balances protection, comfort, and value.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- What's the difference between steel toe and safety-toe boots? Choose the Right Protection for Your Job

- Are safety shoes worth it? The Critical Investment in Workplace Safety & Foot Health

- What is the difference between soft toe and safety-toe? Choose the Right Toe Protection for Your Job

- What distinguishes heavy duty work boots from regular boots? Safety, Durability & Purpose Explained