The key to breaking in new hiking boots is a patient, gradual process that allows the boots to mold to your feet and your feet to adapt to the boots. This involves wearing them for short periods around your home first, then progressing to short walks, and finally to longer hikes with varied terrain and a weighted pack.

The purpose of "breaking in" is not to force a poorly fitting boot to become comfortable, but rather to confirm and finalize the fit of a boot that was chosen correctly from the start. The most critical work happens before you even leave the store.

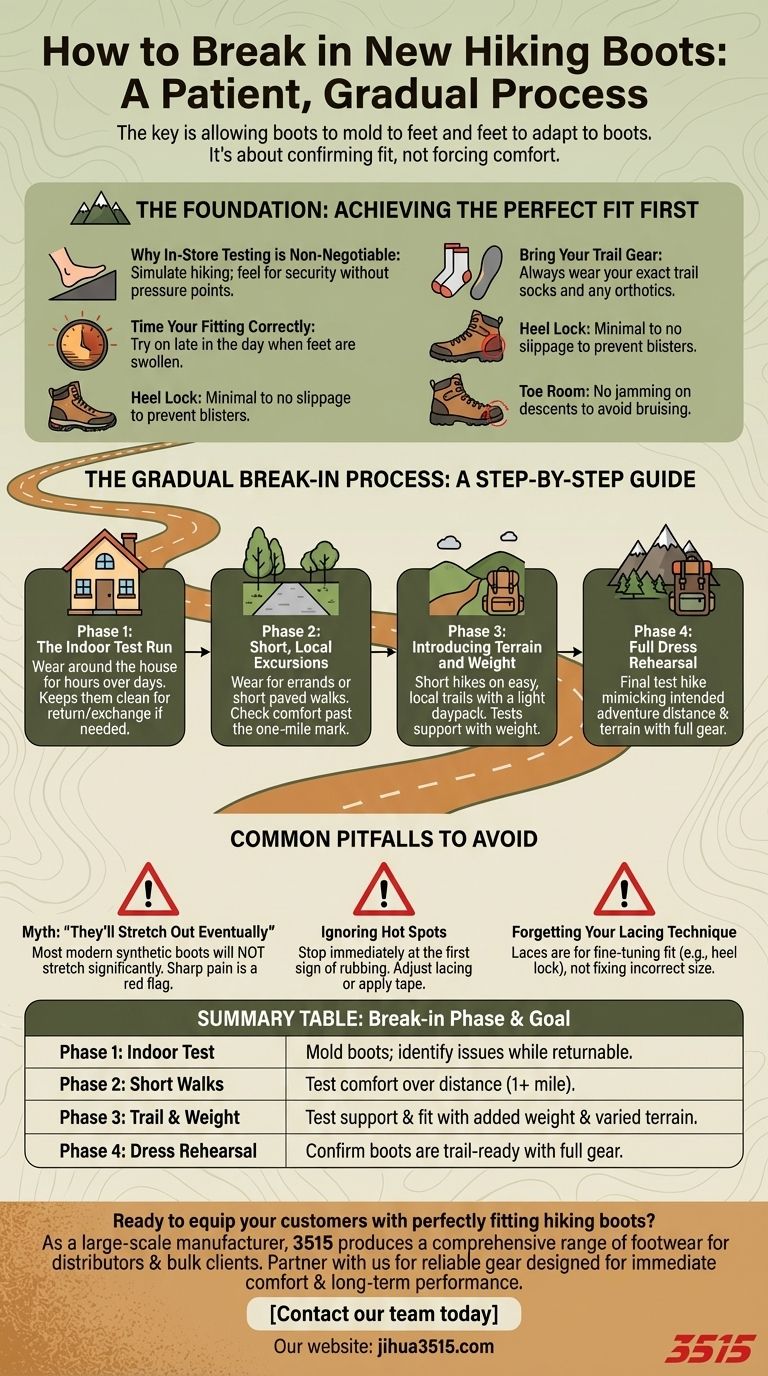

The Foundation: Achieving the Perfect Fit First

Before you can break in a boot, you must select the right one. A break-in period can't fix fundamental fit problems. Pain or significant discomfort are red flags, not hurdles to overcome.

Why In-Store Testing is Non-Negotiable

You need to simulate hiking conditions as much as possible. Walk around the store, find an incline ramp or stairs, and feel how your foot behaves. A good fit feels secure and supportive without any sharp pressure points.

Time Your Fitting Correctly

Try on boots late in the afternoon or evening. Your feet naturally swell throughout the day, and this will give you the most accurate measurement for how they'll feel after a few hours on the trail.

Bring Your Trail Gear

Always try on new boots with the exact socks you plan to hike in. If you use custom orthotics or specialized insoles, bring those as well, as they significantly impact the boot's volume and fit.

The Two Critical Fit Checks

The two most common sources of pain are a sliding heel and cramped toes.

- Heel Lock: Lace the boots snugly (but not tight enough to cut off circulation). Your heel should feel "locked in" with minimal to no slippage as you walk and flex your foot. Excessive heel lift is a primary cause of blisters.

- Toe Room: On a decline or ramp, your toes should not jam into the front of the boot. You should have enough space to wiggle your toes freely. This prevents bruised toes and discomfort on long descents.

The Gradual Break-in Process: A Step-by-Step Guide

Once you've confirmed an excellent initial fit, the methodical break-in process begins. The goal is to slowly increase duration, distance, and difficulty.

Phase 1: The Indoor Test Run

Wear your new boots around the house for a few hours at a time over several days. This allows the heat from your feet to begin molding the boot's materials. Crucially, keeping them clean indoors means you can still return or exchange them if you discover a persistent hot spot or pressure point.

Phase 2: Short, Local Excursions

Once they feel good indoors, wear them for errands or short walks around your neighborhood. Paved surfaces are a good initial test. Pay close attention to how your feet feel as you pass the one-mile mark.

Phase 3: Introducing Terrain and Weight

Graduate to short hikes on easy, local trails. Now is the time to introduce a light daypack. The added weight changes your posture and the forces on your feet, making this a critical test of the boot's support and fit.

Phase 4: Full Dress Rehearsal

Before committing to a major trek, do a final test hike that mimics the distance and terrain of your intended adventure. Wear the socks, pack, and weight you plan to carry. This is your final confirmation that the boots are trail-ready.

Common Pitfalls to Avoid

Trust and objectivity are key when evaluating a new pair of boots. Ignoring warning signs can lead to a miserable experience on the trail.

Myth: "They'll Stretch Out Eventually"

While full-grain leather boots have a small amount of give, most modern hiking boots made with synthetic materials will not stretch significantly. Sharp pain or intense pressure points are signs of a poor fit, not something to be endured.

Ignoring Hot Spots

A "hot spot" is a mild burning or rubbing sensation that is the first sign of a developing blister. When you feel one, stop immediately. Adjust your lacing, check your socks for bunching, or apply moleskin or athletic tape. Pushing through it is a guarantee of pain later.

Forgetting Your Lacing Technique

Your laces are a tool for adjusting fit. A "heel lock" lacing technique can help secure a slipping heel, while skipping an eyelet can relieve pressure on the top of your foot. However, remember that lacing is for fine-tuning, not for fixing a fundamentally incorrect size or shape.

Making the Right Choice for Your Goal

Apply this process based on the type of hiking you do and the boots you've chosen.

- If your primary focus is day hiking on established trails: Lighter, synthetic boots require a less intensive break-in, but the initial in-store fit check is just as critical.

- If your primary focus is multi-day backpacking with a heavy pack: Stiffer, more robust boots demand a longer and more thorough break-in period, with an emphasis on testing them with a fully weighted pack.

- If your primary focus is resolving past issues with blisters: Prioritize the in-store fitting above all else, spending extra time on ramps and confirming a secure heel lock before you even make the purchase.

A methodical approach transforms your new boots from a purchase into a reliable partner for any trail.

Summary Table:

| Break-in Phase | Key Activity | Goal |

|---|---|---|

| Phase 1: Indoor Test | Wear boots around the house for a few hours. | Mold boots to your feet; identify issues while boots are still returnable. |

| Phase 2: Short Walks | Wear for errands or short walks on paved surfaces. | Test comfort over distance (e.g., 1+ mile). |

| Phase 3: Trail & Weight | Short, easy hikes with a light daypack. | Test support and fit with added weight and varied terrain. |

| Phase 4: Dress Rehearsal | A final hike mimicking your planned adventure. | Confirm boots are fully trail-ready with your full gear. |

Ready to equip your customers with perfectly fitting hiking boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and comfortable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of hiking boots and shoes, designed to meet the demands of any trail.

Partner with us to provide your customers with reliable gear that requires a simple, effective break-in process for immediate comfort and long-term performance.

Contact our team today to discuss your footwear needs and explore our catalog.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are the advantages of synthetic materials in hiking boots? Lightweight, Fast-Drying Comfort

- What are the benefits of trail runners compared to hiking boots? Lighter, Faster, More Comfortable

- How does the weight of hiking footwear affect energy expenditure? Boost Your Hiking Efficiency

- What is the first step in caring for synthetic hiking boots? Master the Essential Post-Hike Cleaning Ritual

- What are hiking boots designed for? Ultimate Support & Traction for Rugged Trails

- What are the key steps to ensure proper fitting of hiking boots? A Guide to Ultimate Trail Comfort

- What is the consequence of heel slippage in hiking boots? It can ruin your hike

- Why might someone prefer hiking boots over shoes? Superior Support & Protection for Rugged Terrain