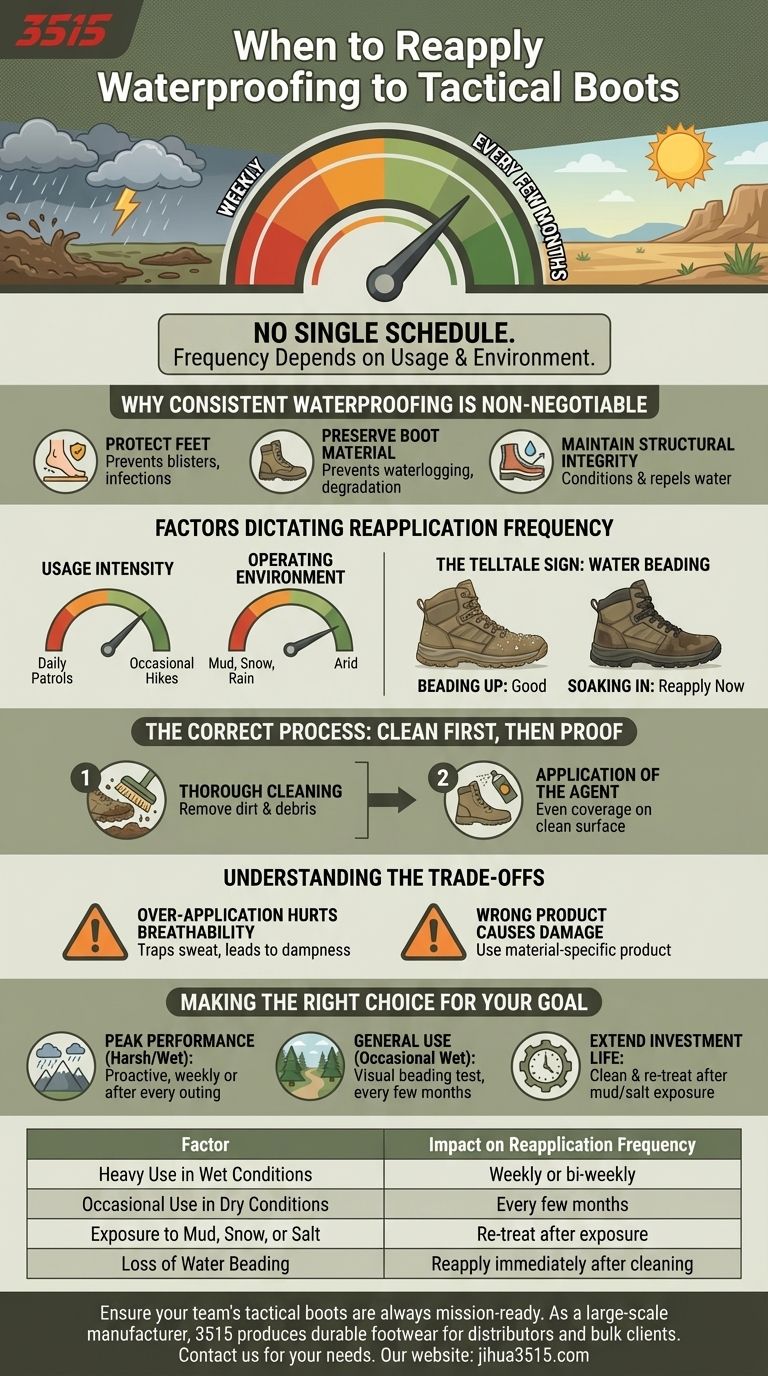

There is no single calendar schedule for reapplying waterproofing to tactical boots. The ideal frequency depends entirely on your usage and environment, ranging from once a week for heavy, wet-weather use to every few months for occasional wear in dry conditions. The key is to reapply the treatment after a thorough cleaning or whenever you notice water is absorbing into the material rather than beading up on the surface.

The core principle of waterproofing maintenance is not about adhering to a strict timeline, but about observing your boots' performance. Reapply the treatment when the material starts to absorb moisture, ensuring your gear is always ready for the conditions you face.

Why Consistent Waterproofing is Non-Negotiable

Properly maintaining your boots' water resistance is about more than just avoiding wet socks. It's a critical practice for foot health, gear longevity, and overall mission readiness.

Protecting Your Feet

Moisture penetrating your boot is a direct threat to your feet. Wet feet are far more susceptible to blisters, fungal infections, and other injuries, which can compromise your comfort and effectiveness in the field.

Preserving the Boot Material

Water saturation can damage the core materials of your boots, whether they are leather or synthetic. Consistent waterproofing prevents the material from becoming waterlogged, which can cause it to stretch, weaken, and degrade over time.

Maintaining Structural Integrity

Conditioning and waterproofing work together. Conditioning nourishes the material to keep it supple and prevent cracking, while waterproofing creates a barrier that repels water. This two-part approach significantly prolongs the durability and performance of your investment.

The Factors That Dictate Reapplication Frequency

Instead of marking a calendar, learn to read the signs. Your boots and your environment will tell you when it's time for a reapplication.

Your Usage Intensity

A boot used for daily patrols in a wet climate will require far more frequent attention than one worn for occasional weekend hikes. For demanding trades or environments, a protective agent might be needed weekly or bi-weekly.

Your Operating Environment

Prolonged exposure to mud, snow, or constant rain will break down a waterproofing treatment much faster than use in an arid environment. After any significant exposure to harsh, wet conditions, you should inspect and likely re-treat your boots.

The Telltale Sign: Water Beading

The most reliable indicator is visual. When your boots are new or freshly treated, water will bead up on the surface and roll off. When the treatment wears down, you'll see water darken the material and begin to soak in. This is your immediate cue to clean and reapply.

The Correct Process: Clean First, Then Proof

You cannot waterproof dirt. Applying a treatment over a dirty boot is ineffective and traps grime that can abrade and damage the material underneath.

Step 1: Thorough Cleaning

Begin by removing all mud, dust, and debris from your boots. Use a brush and, if necessary, a cleaner specifically designed for footwear to ensure the surface is completely clean.

Step 2: Application of the Agent

Once the boots are clean (and dry, depending on the product instructions), apply your waterproofing agent. Whether it's a spray or a wax, ensure you get even coverage, paying special attention to seams and stitching where water is most likely to penetrate.

Understanding the Trade-offs

While essential, it's possible to misapply or over-apply waterproofing, which can lead to its own set of problems.

Over-Application Can Hurt Breathability

Modern tactical boots, especially those with waterproof membranes like Gore-Tex, are designed to be breathable. Applying too much treatment, particularly heavy waxes or oils, can clog the material's pores, trapping sweat and moisture inside the boot. This can lead to the same damp conditions you were trying to avoid.

The Wrong Product Causes Damage

Always use a waterproofing product that is explicitly designed for your boot's material. Using a product intended for full-grain leather on a synthetic or suede boot can cause discoloration, damage the material, and void the manufacturer's warranty.

Making the Right Choice for Your Goal

Your reapplication strategy should be tailored to your specific needs and usage patterns.

- If your primary focus is peak performance in harsh, wet environments: Proactively reapply your waterproofing treatment after every significant outing or deep cleaning, potentially on a weekly basis.

- If your primary focus is general use with occasional exposure to wetness: Rely on the visual water beading test and plan to reapply every few months as a part of your regular maintenance routine.

- If your primary focus is extending the life of your investment: Make it a rule to always clean and re-treat your boots after they have been exposed to mud, salt, or excessive moisture.

Ultimately, disciplined maintenance is what transforms a good pair of boots into reliable, long-serving equipment.

Summary Table:

| Factor | Impact on Reapplication Frequency |

|---|---|

| Heavy Use in Wet Conditions | Weekly or bi-weekly |

| Occasional Use in Dry Conditions | Every few months |

| Exposure to Mud, Snow, or Salt | Re-treat after exposure |

| Loss of Water Beading | Reapply immediately after cleaning |

Ensure your team's tactical boots are always mission-ready. As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our expertise in materials and construction ensures your gear performs in the toughest conditions. Contact us today to discuss your footwear needs and benefit from our extensive production capabilities.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

People Also Ask

- What are the characteristics of tactical shoe midsoles? Find the Perfect Balance of Support & Durability

- What protective features are commonly found in tactical boots but not in regular boots? Engineered for High-Stakes Performance

- What are the benefits of heavier tactical boots? Superior Protection & Durability for Demanding Missions

- What are the advantages of tactical boots? Unmatched Agility & Durability for Professionals

- How do sturdy uppers enhance tactical boots? Boosting Ankle Stability and Protection

- What is the benefit of lightweight tactical boots? Boost Speed & Endurance for Your Mission

- Why is footwear important for operators in different environments? Choose the Right Boot for Your Mission

- What are the steps for cleaning tactical boots? A 5-Step Guide to Preserve Your Gear