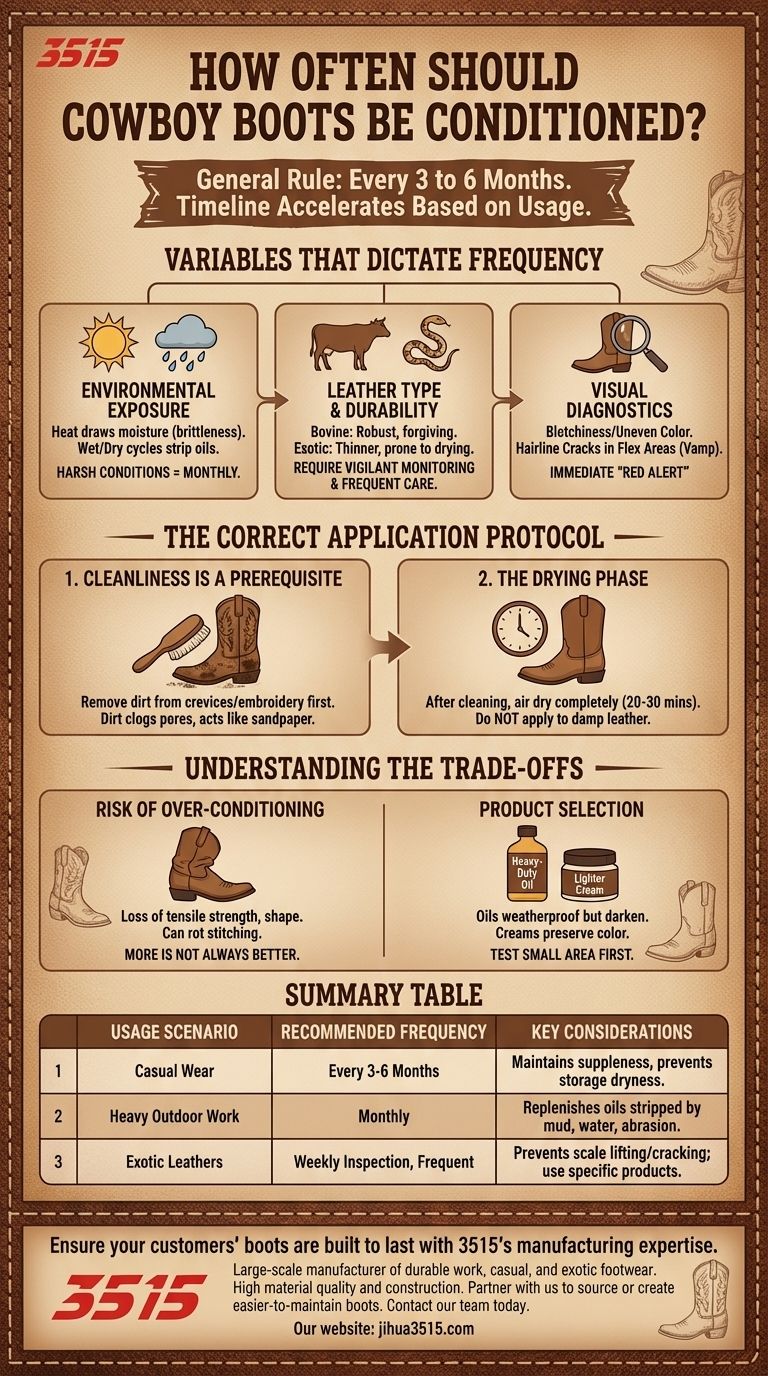

As a general rule, cowboy boots should be conditioned every three to six months to maintain their structural integrity. However, this timeline accelerates significantly based on usage: heavy-duty work boots exposed to mud, heat, or rain require monthly attention, while delicate exotic leathers generally demand more frequent care than standard cowhide.

Leather is effectively a skin that no longer has a body to replenish its moisture. Conditioning is not merely cosmetic; it is a critical maintenance step required to restore natural oils, prevent permanent cracking, and ensure the leather remains pliable and water-resistant.

The Variables That Dictate Frequency

While the "three to six months" rule applies to the average user, relying strictly on a calendar is often insufficient. You must adjust your schedule based on the specific stresses placed on the leather.

Environmental Exposure

The environment is the primary enemy of leather longevity. Exposure to heat draws moisture out of the hide, leading to brittleness.

Conversely, distinct cycles of wetting and drying—common with mud or rain—strip natural oils rapidly. If your boots face these harsh conditions, a monthly conditioning routine is necessary.

Leather Type and Durability

Not all leathers react to dryness at the same rate. Standard full-grain bovine leather is robust and forgiving.

Exotic leathers, such as snake or lizard, are often thinner and prone to drying out much faster. These require vigilant monitoring and more frequent conditioning to prevent the scales from lifting or cracking.

Visual Diagnostics

Your boots will often signal when they need attention before the calendar does.

Inspect the leather for blotchiness or uneven color, which indicates uneven drying. Fine hairline cracks in high-flex areas, such as the vamp (where the foot bends), are an immediate "red alert" that the fibers are dehydrated.

The Correct Application Protocol

Applying conditioner to dirty boots is a critical error that can do more harm than good.

Cleanliness is a Prerequisite

Conditioner is designed to penetrate the pores of the leather. If these pores are clogged with dirt, the conditioner cannot absorb.

Worse, applying conditioner over debris traps grit against the leather, which acts like sandpaper and degrades the finish. Always use a soft brush or cloth to remove dirt from crevices and embroidery first.

The Drying Phase

After using a leather-specific cleaner, patience is required.

Allow the boots to air dry completely—typically for 20 to 30 minutes—before applying conditioner. Applying product to damp leather can inhibit absorption and potentially trap moisture where it shouldn't be.

Understanding the Trade-offs

More conditioning is not always better. It is possible to over-maintain your boots, leading to diminished performance.

The Risk of Over-Conditioning

While dryness causes cracking, excessive oil saturation can cause the leather to become too soft.

If leather loses its tensile strength, the boot loses its shape and support. Over-conditioning can also rot the stitching in the welt, leading to costly repairs.

Product Selection

Universal conditioners may not work for every pair.

Heavy-duty work oils are excellent for weatherproofing but may darken the leather significantly. Lighter creams are better for dress boots where maintaining the original color is a priority. Always test a small, inconspicuous area first.

Making the Right Choice for Your Goals

To ensure your boots last for decades rather than years, align your maintenance schedule with your usage patterns.

- If your primary focus is casual wear: Condition every 3 to 6 months to maintain suppleness and prevent dryness from storage.

- If your primary focus is heavy outdoor work: Condition monthly to replenish oils stripped by mud, water, and abrasion.

- If your primary focus is preserving exotic leather: Inspect weekly for dryness and condition frequently using products specifically formulated for reptile or exotic hides.

The goal of conditioning is to keep the leather functioning as a protective barrier, ensuring the upper outlasts the sole.

Summary Table:

| Usage Scenario | Recommended Conditioning Frequency | Key Considerations |

|---|---|---|

| Casual Wear | Every 3-6 Months | Maintains suppleness, prevents storage dryness |

| Heavy Outdoor Work | Monthly | Replenishes oils stripped by mud, water, and abrasion |

| Exotic Leathers (Snake, Lizard) | Weekly Inspection, Frequent Conditioning | Prevents scale lifting/cracking; use specific products |

Ensure your customers' boots are built to last with 3515's manufacturing expertise.

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots, casual boots, and exotic leather footwear, ensuring the highest standards of material quality and construction.

Partner with us to source or create boots that are easier to maintain and built for longevity. Contact our team today to discuss your production needs and how we can add value to your supply chain.

Visual Guide

Related Products

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How does the cork filling contribute to the comfort of Goodyear welted shoes? Discover the Secret to Custom Foot Support

- What is Athlete's Foot, and how does it spread? Prevent Contagious Fungal Infections

- Why are fixed signal anchors necessary for PPE positioning systems? Ensuring Life-Saving Indoor Accuracy

- What is the role of OSHA in workplace safety? Ensuring Compliance and Protecting Workers

- Why is the systematic distribution of PPE essential in construction? Secure Your Site with Pre-Deployment Safety

- What is the necessity of providing standardized professional cycling shoes and cleats? Ensuring Data Purity

- Why is Polyethylene (PE) used as a matrix material in mechanical simulations? Optimize Your Footwear Lattice Design

- What is the purpose of integrating a low-power microcontroller to assist the main processor in smart wearable systems? Boost Efficiency & Battery Life