At its core, the cork filling in a Goodyear welted shoe acts as a dynamic internal footbed. It is a layer of granulated cork placed in the cavity between the insole and outsole, which over time, compresses and molds precisely to the shape of your foot. This process creates a personalized fit that provides custom support and cushioning.

The primary contribution of cork is not immediate, cloud-like comfort, but the gradual creation of a custom-molded footbed. This provides unparalleled long-term support by distributing your weight evenly and matching the unique contours of your foot.

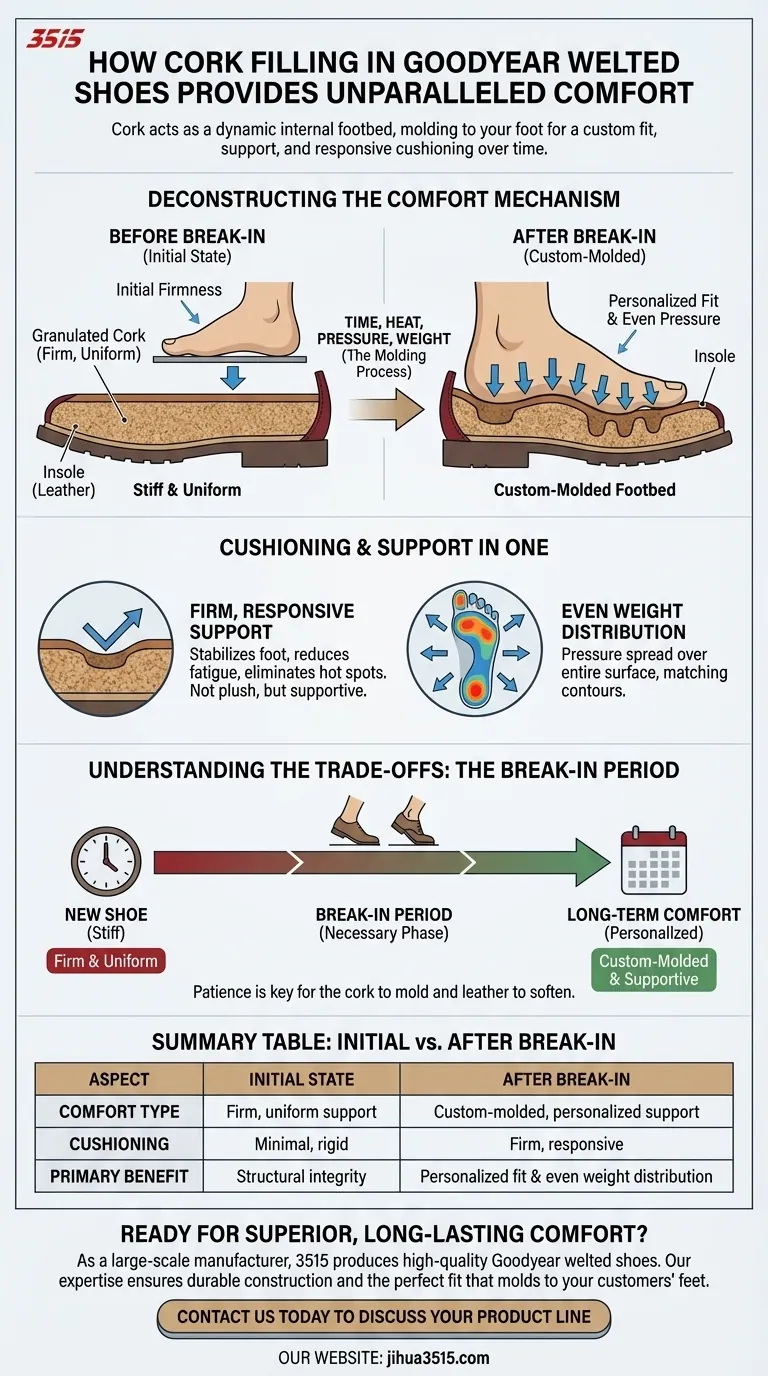

Deconstructing the Comfort Mechanism

To understand the role of cork, you must first visualize the shoe's architecture. The Goodyear welt construction method creates a unique internal structure that makes the use of a filling like cork possible.

The Cavity Between Insole and Outsole

The process of stitching the welt (a strip of leather) to the insole and upper creates a small, empty void. This cavity sits directly beneath your foot, separated only by the leather insole.

This space is then filled with a thick layer of granulated cork mixed with a light adhesive. Initially, this layer is relatively firm and uniform.

The Molding Process: A Personalized Footbed

As you wear the shoes, your body weight, pressure, and heat work together to soften and compress the cork filling. The cork granules shift and compact under the high-pressure points of your foot, such as the ball and heel.

Over the course of several wears, this process creates a distinct impression of your foot in the cork layer. This transforms the flat insole into a custom-molded footbed, providing a level of personalized fit that a generic, pre-made shoe cannot offer.

Cushioning and Support in One

The compressed cork doesn't just create a shape; it also provides a unique form of cushioning. Unlike soft foam, which simply absorbs impact, the molded cork provides firm, responsive support.

This firm foundation helps to stabilize the foot and distribute pressure evenly across its entire surface. This reduces fatigue and eliminates the "hot spots" that often cause discomfort in other shoes.

Understanding the Trade-offs

The benefits of a cork footbed are significant, but they are not immediate. This is the most critical factor to understand when considering Goodyear welted footwear.

The "Break-In" Period

New Goodyear welted shoes are notoriously stiff. This stiffness is partly due to the thick leather components but also to the uncompressed cork filling.

The shoe requires a break-in period for the cork to mold and the leather to soften. This initial phase can be less comfortable than wearing a modern sneaker, but it is a necessary step in the personalization process.

Firmness vs. Softness

The comfort provided by cork is one of support and alignment, not plush softness. If you are accustomed to the immediate, springy cushion of gel or foam midsoles found in athletic shoes, the feel of a cork footbed will be very different.

Cork offers a stable base that supports your foot's natural structure, which many find more comfortable for long periods of standing or walking once the break-in period is complete.

Making the Right Choice for Your Comfort Needs

Choosing the right shoe depends entirely on what you prioritize. The cork footbed in a Goodyear welted shoe offers a specific type of benefit that isn't for everyone.

- If your primary focus is immediate, out-of-the-box comfort: A shoe with a modern foam or gel midsole may be a better initial choice.

- If your primary focus is long-term, personalized support: The cork filling in a Goodyear welted shoe is unparalleled once the break-in period is complete.

- If your primary focus is durability and a custom fit: The molding property of cork, combined with the resoleable nature of the Goodyear welt, creates a shoe that gets more comfortable with age.

Ultimately, the cork filling is the mechanism that allows the shoe to become a unique extension of your own foot.

Summary Table:

| Aspect | Initial State | After Break-In |

|---|---|---|

| Comfort Type | Firm, uniform support | Custom-molded, personalized support |

| Cushioning | Minimal, rigid | Firm, responsive |

| Primary Benefit | Structural integrity | Personalized fit & even weight distribution |

| Ideal For | Long-term investment in footwear | All-day standing or walking comfort |

Ready to experience the superior, long-lasting comfort of custom-molded footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures durable construction and the perfect fit that molds to your customers' feet.

Contact us today to discuss how we can bring this unparalleled comfort to your product line.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What types of dress shoes are recommended for formal occasions? A Guide to Impeccable Style

- What should someone do if they are unsure about a company's dress code? Navigate with Confidence

- What are the long-term benefits of investing in quality dress shoes? Save Money & Boost Your Style

- What are the key considerations when choosing dress shoes for formal occasions? A Guide to Style, Color & Quality

- How can one balance a casual outfit when wearing dress shoes? Achieve a Polished Smart Casual Look