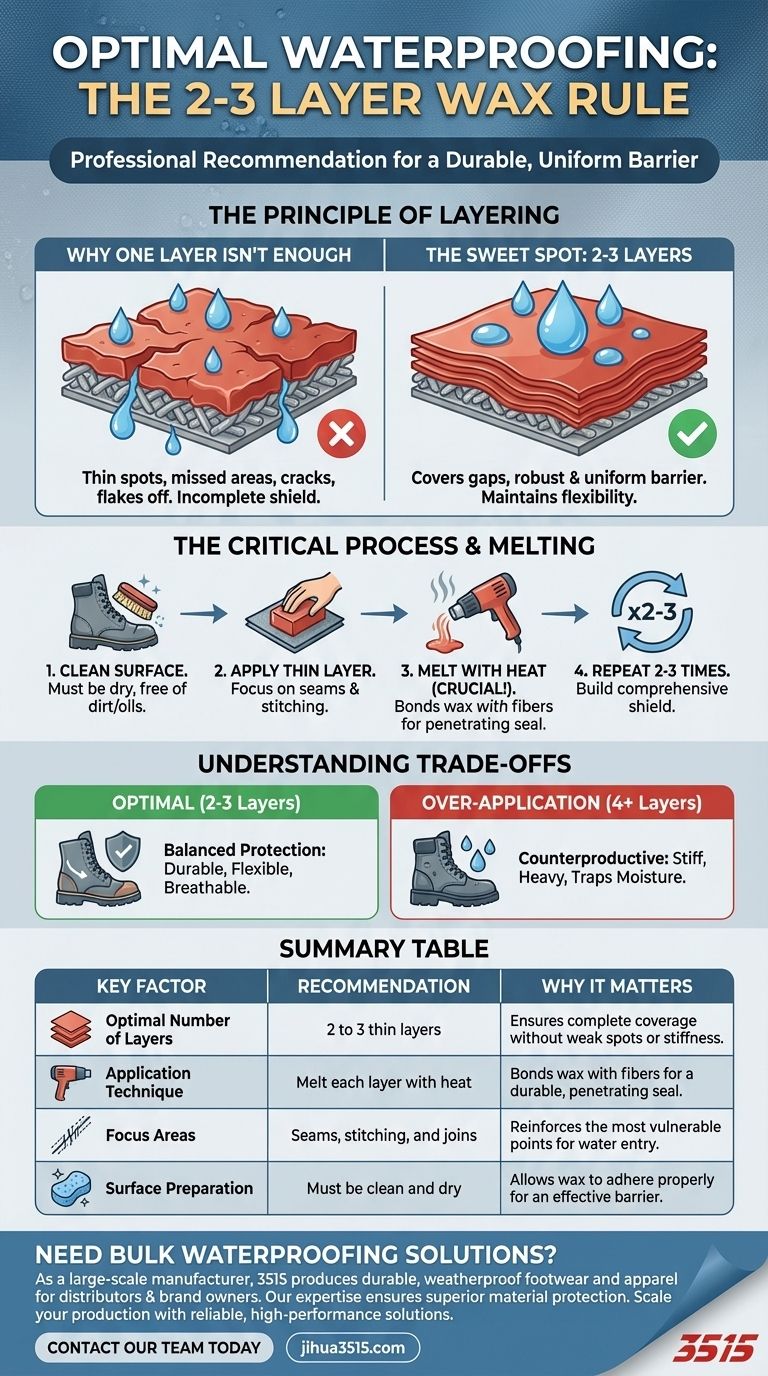

For optimal waterproofing, the professional recommendation is to apply two to three thin layers of wax. This method ensures you achieve a complete and even barrier, effectively sealing the material without leaving microscopic gaps or weak points that a single, heavy coat might create.

The goal is not simply to apply wax, but to create a uniform, non-porous barrier. Multiple thin layers, with each one melted into the fabric, are far more effective at achieving this than one thick, inconsistent layer.

The Principle of Layering for a Durable Seal

Achieving a truly waterproof finish with wax is a game of millimeters. It's about building a comprehensive shield, and the layering process is fundamental to that success.

Why One Layer Isn't Enough

A single application of wax, no matter how carefully applied, will almost certainly have thin spots or missed areas. These tiny imperfections become entry points for water, defeating the purpose of the treatment.

Furthermore, a single thick coat tends to sit on the surface and can crack or flake off as the material flexes.

The Sweet Spot: Two to Three Layers

Applying a second layer covers any gaps left by the first. A third layer provides an even greater level of security, ensuring an exceptionally robust and uniform barrier.

This range strikes the perfect balance between total coverage and maintaining the material's flexibility.

The Critical Role of Melting

Melting each layer is a non-negotiable step. Using a hairdryer or heat gun on a low setting allows the wax to transition from a surface coating into a penetrating sealant.

This process helps the wax bond with the fibers of the material, creating a much more durable and effective seal from within.

Understanding the Process and Trade-offs

Proper application technique is just as important as the number of layers. Rushing the process will lead to a subpar result.

Start with a Clean Surface

Before you begin, the item must be completely clean and dry. Dirt, dust, or oils will prevent the wax from adhering properly to the material, creating points of failure in your waterproof barrier.

Focus on Vulnerable Areas

Pay special attention to seams, stitching, and any areas where different materials join. These are the most common points for water to penetrate, so ensure they receive thorough coverage with each layer.

The Downside of Over-Application

While 2-3 layers are optimal, applying four or more can be counterproductive. Too much wax can make fabric overly stiff, heavy, and can significantly reduce its breathability, potentially trapping moisture from sweat inside.

Making the Right Choice for Your Gear

Use the item's purpose to guide your application. The goal is to match the level of protection to the expected use.

- If your primary focus is maximum durability for heavy-use gear (like work boots or canvas packs): Apply a full three layers, taking extra care to melt each one thoroughly into the seams.

- If your primary focus is water resistance for casual items (like sneakers or a light jacket): Two carefully applied layers will likely provide all the protection you need without compromising flexibility.

Ultimately, a patient and methodical approach to layering will yield a waterproof seal you can rely on.

Summary Table:

| Key Factor | Recommendation | Why It Matters |

|---|---|---|

| Optimal Number of Layers | 2 to 3 thin layers | Ensures complete coverage without weak spots or stiffness. |

| Application Technique | Melt each layer with heat | Bonds wax with fibers for a durable, penetrating seal. |

| Focus Areas | Seams, stitching, and joins | Reinforces the most vulnerable points for water entry. |

| Surface Preparation | Must be clean and dry | Allows wax to adhere properly for an effective barrier. |

Need to waterproof gear in bulk? As a large-scale manufacturer, 3515 produces a comprehensive range of durable, weatherproof footwear and apparel for distributors, brand owners, and bulk clients. Our expertise in material treatment ensures your products offer superior protection. Let us help you scale your production with reliable, high-performance solutions.

Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What materials are waterproof boots typically made of? A Guide to Rubber, Leather & Membranes

- What are some ways to avoid unnecessary damage to work boots? Extend Their Lifespan with Simple Habits

- What is the difference between traditional cowboy boots and roper boots? Choose the Right Boot for Your Needs

- How does the height of PVC work boots affect their protective capabilities? Find the Perfect Balance for Your Job

- What are the common types of women's work boots? Find the Right Boot for Your Job's Hazards

- How do you apply waterproof wax to leather boots? A Guide to Maximum Protection & Longevity

- What product is recommended to protect leather boots from water saturation? Use a Wax-Based Conditioner

- Which boots do real cowboys wear? Discover the Top Work Boots for Ranch Durability