At their core, waterproof boots rely on a combination of inherently non-porous materials and advanced fabric technology. The most common materials are rubber, synthetic compounds like polyurethane and PVC, specially treated leather, and textiles like nylon that are paired with an internal waterproof membrane. The specific material choice depends entirely on the boot's intended use, from a simple rain boot to a technical hiking boot.

True waterproofing in footwear is achieved in two primary ways: by using naturally impermeable materials like rubber, or by engineering a multi-layer system that pairs a durable outer material with a high-tech waterproof and breathable membrane inside.

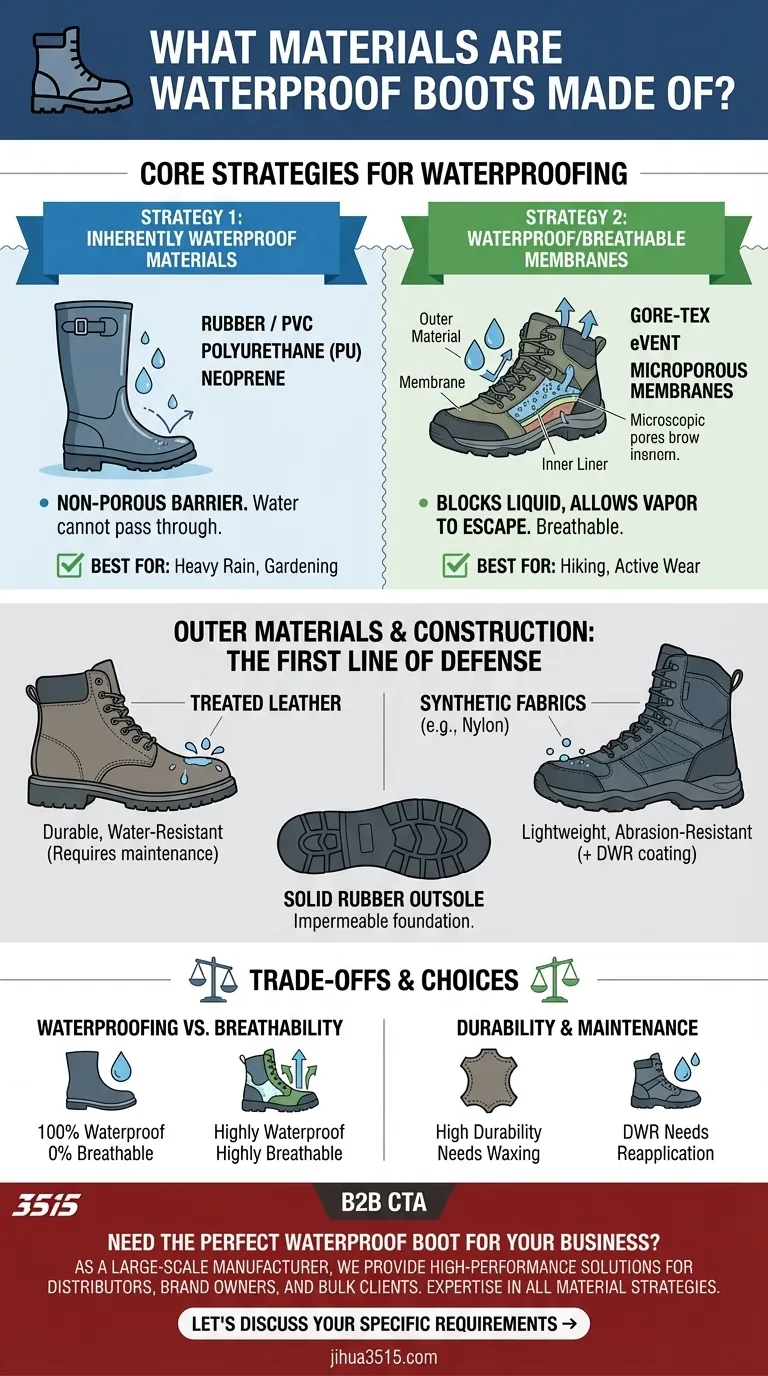

The Two Core Strategies for Waterproofing

Understanding how a boot keeps water out comes down to recognizing which of the two fundamental strategies its design employs. Each has distinct advantages for different environments.

Strategy 1: Inherently Waterproof Materials

This is the most straightforward approach, using materials that are naturally a barrier to water.

The most classic example is rubber or PVC (polyvinyl chloride). These materials are non-porous, meaning water molecules simply cannot pass through them. They form the basis of traditional rain boots and Wellingtons.

Modern synthetics like polyurethane (PU) and neoprene are also used for uppers. They offer more flexibility and lighter weight than traditional rubber while still being intrinsically waterproof.

Strategy 2: Waterproof/Breathable Membranes

This advanced approach is the standard for performance footwear like hiking and work boots, where breathability is just as important as waterproofing.

This system relies on a specialized internal liner, or "bootie," made of a microporous membrane. The most well-known brand is Gore-Tex, but others like eVent function on a similar principle.

These membranes contain billions of microscopic pores per square inch. The pores are small enough to block liquid water droplets from entering but large enough to allow water vapor (sweat) to escape, keeping your feet dry from both the outside and inside.

The Role of Outer Materials and Construction

The outer part of the boot you see is the first line of defense. It works in tandem with the core waterproofing strategy to provide durability and protection.

Treated Leather

High-quality leather is not naturally waterproof, but it is highly water-resistant and durable. It is treated with oils, waxes, or other compounds to repel water effectively. In most modern performance boots, treated leather is paired with an internal waterproof membrane for guaranteed protection.

Synthetic Fabrics

Materials like nylon are common in hiking and tactical boots due to their light weight and abrasion resistance. The exterior fabric is almost always treated with a Durable Water Repellent (DWR) coating that causes water to bead up and roll off. However, the DWR is only for water resistance; the internal membrane provides the true waterproofing.

The Critical Outsole

Regardless of the upper, the outsole of a waterproof boot is almost universally made from solid rubber or a dense synthetic composite. This creates an impermeable foundation that prevents water from soaking up from the ground.

Understanding the Trade-offs

No single material is perfect for every situation. Choosing the right boot means understanding the compromises inherent in each design.

Waterproofing vs. Breathability

This is the central trade-off. A solid rubber boot is 100% waterproof but offers zero breathability, which can lead to sweaty, uncomfortable feet during strenuous activity.

A boot with a Gore-Tex membrane is highly waterproof and highly breathable. However, it is more complex to manufacture, costs more, and the membrane's effectiveness can be compromised if it gets clogged with dirt or oils.

Durability and Maintenance

Treated leather is exceptionally durable but requires periodic maintenance. The waterproofing waxes or oils must be reapplied to maintain the leather's health and water repellency.

Synthetic uppers with a DWR coating also need care. This coating wears off over time with use and abrasion and will need to be reapplied with a spray-on treatment to maintain peak performance.

Making the Right Choice for Your Needs

Selecting the right material depends entirely on your intended activity and environment.

- If your primary focus is absolute waterproofing for short durations (e.g., rain or gardening): Rubber or PVC boots are the most direct and cost-effective solution.

- If your primary focus is hiking or all-day wear in wet conditions: Look for boots with a waterproof/breathable membrane like Gore-Tex, combined with a leather or synthetic upper.

- If your primary focus is durable, water-resistant work boots: Treated leather is an excellent choice, often reinforced with a membrane and sealed seams for maximum protection.

Understanding these material strategies allows you to select footwear that truly matches the demands of your environment.

Summary Table:

| Material / System | Key Characteristics | Best For |

|---|---|---|

| Rubber / PVC | Inherently waterproof, non-porous, durable | Heavy rain, gardening, wet environments |

| Treated Leather | Durable, water-resistant, requires maintenance | Work boots, durable everyday wear |

| Waterproof Membrane (e.g., Gore-Tex) | Blocks water, allows vapor (sweat) to escape, breathable | Hiking, all-day wear, strenuous activity |

| Synthetic Fabrics (e.g., Nylon) | Lightweight, abrasion-resistant, often paired with a membrane | Hiking boots, tactical boots |

Need the Perfect Waterproof Boot for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance waterproof footwear for distributors, brand owners, and bulk clients. Our expertise covers all material strategies, from durable rubber and treated leather to advanced breathable membranes, ensuring the right boot for every market need and environment.

We can help you:

- Source or custom-manage a full line of reliable waterproof boots.

- Leverage our production capabilities for all types of shoes and boots at scale.

- Ensure quality and performance for your customers.

Let's discuss your specific requirements → Contact Our Team Today

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What should be kept in mind when trying on boots? A Guide to the Perfect Fit

- Why were traditional leather conditioners ineffective for firefighter boots? The Hidden Danger of Sealing vs. Breathing

- What are the key features of logger boots? A Guide to Unmatched Stability & Safety

- What are the key criteria for selecting firefighter boots? Ensure Maximum Safety and Performance

- How should work boots fit properly? A Guide to All-Day Comfort and Safety

- How do the design and function of western boots differ from work boots? Choosing the Right Footwear for Your Environment

- How are PVC work boots manufactured? An Inside Look at Injection Molding

- What are the benefits of rubber boots for farm work? Unbeatable Protection in Wet & Muddy Conditions