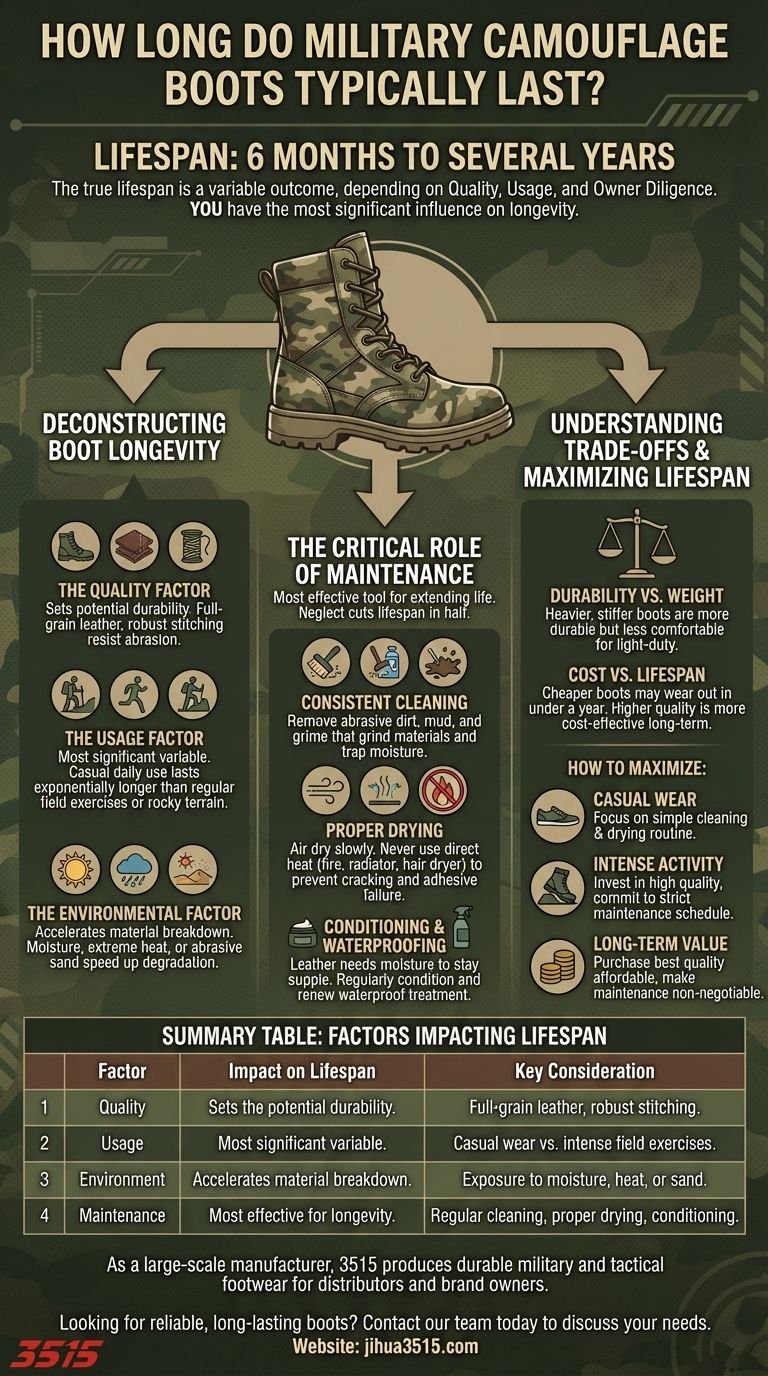

To be direct, a pair of high-quality military camouflage boots can last anywhere from six months to several years. This wide range exists because the true lifespan is less about a fixed timeline and more about the interplay between the boot's quality, the intensity of its use, and the diligence of its owner.

The key takeaway is that you, the owner, have the most significant influence on your boots' longevity. While quality sets the potential, proper care and maintenance are what actually determine whether they last for a few months or for several years.

Deconstructing Boot Longevity

The lifespan of a military boot is not a single number but a variable outcome. It's determined by a combination of inherent quality and external factors that you can often control.

The Quality Factor

The materials and construction methods used are the foundation of a boot's durability. Premium boots utilize full-grain leather, high-denier nylon, and robust stitching techniques that resist abrasion and failure under stress.

The Usage Factor

How you use your boots is the single most significant variable. A pair worn for casual daily use will last exponentially longer than a pair subjected to regular field exercises, hiking on rocky terrain, or daily patrols.

The Environmental Factor

The climate and environment in which you wear the boots also play a critical role. Constant exposure to moisture, extreme heat, or abrasive desert sand will accelerate the breakdown of materials far more quickly than temperate, dry conditions.

The Critical Role of Maintenance

Proper care is not optional; it is the most effective tool for extending the life of your investment. Neglecting maintenance can cut a boot's potential lifespan in half, regardless of its initial quality.

Consistent Cleaning

Dirt, mud, and grime are abrasive. They grind away at leather and fabric fibers and can trap moisture, which leads to material rot. Cleaning your boots regularly after heavy use is essential.

Proper Drying

Never dry wet boots with direct heat from a fire, radiator, or hair dryer. This can cause leather to crack and adhesives to fail. Always allow them to air dry slowly and naturally in a well-ventilated area.

Conditioning and Waterproofing

Leather is a skin and requires moisture to stay supple. Regular conditioning prevents it from drying out and cracking. Similarly, renewing the waterproof treatment keeps moisture out, protecting both your feet and the boot's internal structure.

Understanding the Trade-offs

Choosing the right boot involves balancing competing priorities. What makes a boot excellent for one task can be a disadvantage in another.

Durability vs. Weight

The most rugged, durable boots are often heavier and stiffer. While this provides maximum protection and longevity in harsh conditions, it can be uncomfortable and excessive for light-duty or everyday wear.

Cost vs. Lifespan

A cheaper pair of boots may seem like a good value upfront, but they often use inferior materials and construction. They may wear out in under a year, making a more expensive, high-quality pair a more cost-effective choice in the long run.

How to Maximize Your Boots' Lifespan

Your approach should be dictated by your primary use case.

- If your primary focus is daily casual wear: Choose a lighter, more flexible boot and focus on a simple routine of keeping them clean and dry.

- If your primary focus is intense outdoor activity: Invest in a high-quality, ruggedly constructed boot and commit to a strict maintenance schedule of cleaning, drying, and conditioning after every major use.

- If your primary focus is maximizing long-term value: Purchase the highest quality boots you can afford and treat maintenance as a non-negotiable part of ownership from day one.

Ultimately, how long your boots last is a direct reflection of the care you put into them.

Summary Table:

| Factor | Impact on Lifespan | Key Consideration |

|---|---|---|

| Quality | Sets the potential durability. | Full-grain leather, robust stitching. |

| Usage | Most significant variable. | Casual wear vs. intense field exercises. |

| Environment | Accelerates material breakdown. | Exposure to moisture, heat, or sand. |

| Maintenance | Most effective for longevity. | Regular cleaning, proper drying, conditioning. |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable military and tactical footwear for distributors, brand owners, and bulk clients.

Are you looking for reliable, long-lasting boots built to withstand demanding conditions? Our production capabilities encompass all types of military boots, ensuring quality and durability for your customers or personnel.

Contact our team today to discuss your specific needs and discover how we can provide the right footwear solution for you.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

People Also Ask

- What factors affect the lifespan of desert boots? A Guide to Maximizing Durability and Comfort

- What are the characteristics of full grain leather used in military boots? Unmatched Durability & Fit

- Can jungle boots be used for wading and hiking? Master Water Management in Hot, Humid Climates

- What are the main differences between combat boots and jump boots? A Guide to Purpose-Built Footwear

- Why is ankle support important in motorcycle boots? Prevent Catastrophic Injuries in a Crash

- How did combat boots evolve historically? From Roman Sandals to Modern Tactical Gear

- How should desert boots be laced? Achieve the Perfect, Classic Fit

- What historical event marked the first use of camouflage in military apparel? The Napoleonic Wars' Tactical Shift