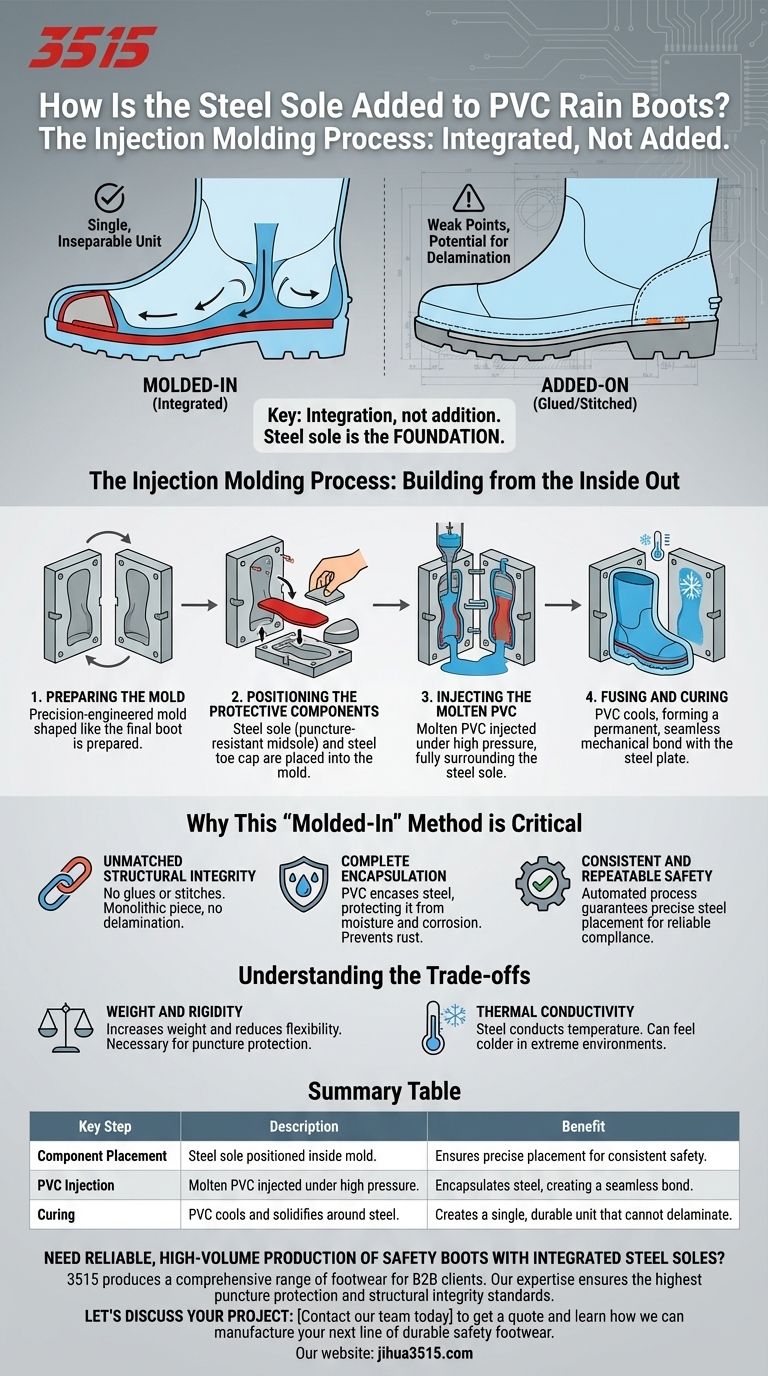

In PVC rain boot production, the steel sole is integrated directly into the boot during the injection molding process. The steel component is placed into the boot mold first, before the molten PVC material is injected, ensuring it becomes a permanent and fully encapsulated part of the sole.

The key to this process is integration, not addition. The steel sole isn't attached later; it is the foundation around which the PVC sole is formed, creating a single, inseparable unit for maximum durability and safety.

The Injection Molding Process: Building from the Inside Out

To understand how the steel sole is added, you must first understand the fundamental manufacturing process for these boots: direct injection molding. This method builds the boot in a single, high-pressure operation.

Preparing the Mold

The process begins with a precision-engineered, two-part mold shaped like the final boot. This mold is prepared to receive the components that will form the boot's structure.

Positioning the Protective Components

This is the critical step for safety features. The steel sole, also known as a puncture-resistant midsole, is placed into its designated position at the bottom of the mold. If the boot also requires a steel toe cap, that is set in place at the front of the mold at the same time.

Injecting the Molten PVC

Once the steel components are secured within the mold, it is closed. Molten Polyvinyl Chloride (PVC) is then injected under extremely high pressure.

Fusing and Curing

The hot, liquid PVC flows into every cavity of the mold, completely surrounding and encapsulating the steel sole. As the PVC cools and solidifies, it forms a permanent, mechanical bond with the steel plate, fusing it into a single, seamless sole unit.

Why This "Molded-In" Method is Critical

This manufacturing technique is not accidental; it is essential for creating reliable safety footwear. The benefits are directly tied to the process itself.

Unmatched Structural Integrity

Because the steel is molded directly into the PVC, there are no glues, stitches, or other weak points that could fail under stress. The sole is a monolithic piece, making delamination or separation of the steel plate virtually impossible.

Complete Encapsulation

The PVC material fully encases the steel sole, protecting it from moisture, chemicals, and other corrosive elements. This prevents rust and degradation, ensuring the protective feature lasts the entire lifespan of the boot.

Consistent and Repeatable Safety

Injection molding is a highly automated and precise process. This guarantees that every boot produced has the steel sole placed in the exact same position, ensuring consistent quality and reliable compliance with safety standards.

Understanding the Trade-offs

While highly effective, integrating a steel sole has inherent trade-offs that are important to recognize.

Weight and Rigidity

The most obvious trade-off is an increase in weight and a decrease in flexibility. The steel component adds rigidity to the sole, which is necessary for puncture protection but can reduce comfort during long periods of walking.

Thermal Conductivity

Steel is a conductor of temperature. In very cold environments, boots with steel soles can feel colder than their non-steel counterparts, as the metal can transfer cold from the ground to the foot.

What This Means for Your Choice in Footwear

Understanding this integrated manufacturing process helps you make a more informed decision when selecting protective boots.

- If your primary focus is maximum puncture protection: Always look for boots made with a direct-injection method where the steel midsole is an integral component.

- If your primary focus is lightweight flexibility in a low-risk environment: A standard PVC boot without the integrated steel components may be a more comfortable and suitable option.

Ultimately, knowing the steel sole is molded in—not just added on—gives you confidence that the safety feature is a core part of the boot's design.

Summary Table:

| Key Step | Description | Benefit |

|---|---|---|

| Component Placement | Steel sole is positioned inside the boot mold. | Ensures precise placement for consistent safety. |

| PVC Injection | Molten PVC is injected under high pressure. | Encapsulates the steel, creating a seamless bond. |

| Curing | PVC cools and solidifies around the steel. | Creates a single, durable unit that cannot delaminate. |

Need reliable, high-volume production of safety boots with integrated steel soles?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our direct injection molding expertise ensures every pair of boots meets the highest standards for puncture protection and structural integrity.

Let's discuss your project: Contact our team today to get a quote and learn how we can manufacture your next line of durable safety footwear.

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How should Wellington boots fit? Find the Perfect Balance of Comfort and Security

- How should you clean the inside of rubber boots? Eliminate Odors & Extend Boot Life

- How do muck boots differ from traditional Wellingtons? Choose the Right Footwear for Your Outdoor Work

- What factors determine the carbon footprint of Wellington boots? Material, Durability, and Your Environmental Impact

- What are the benefits of wearing Wellington boots in winter? Stay Dry and Warm in Wet Conditions

- How is natural rubber different from synthetic materials like PVC and Neoprene in boots?

- Why are eco-friendly wellies important? Switch to Sustainable Footwear for a Greener Future

- What is the historical background of wellington boots? From Military Kit to Modern Staple