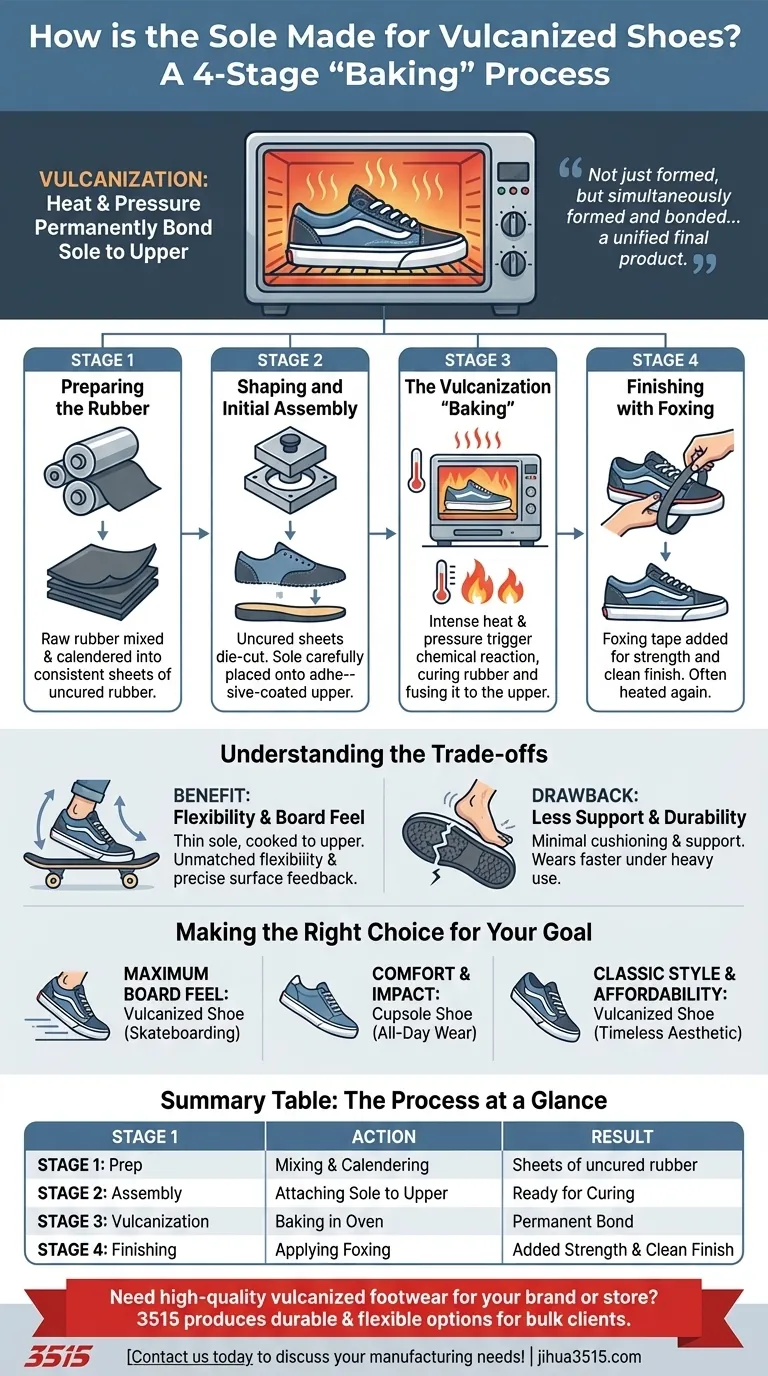

At its core, the sole of a vulcanized shoe is made by taking soft, uncured rubber, attaching it to the shoe's upper, and then baking the entire assembly in a high-temperature oven. This process, known as vulcanization, uses heat and pressure to create a chemical reaction that permanently bonds the rubber sole to the upper, resulting in a single, integrated unit.

The key isn't just how the rubber sole is formed, but how it is simultaneously formed and bonded to the rest of the shoe in a single, high-heat process, creating a distinctively flexible and unified final product.

The Vulcanized Sole Construction Process

The creation of a vulcanized sole is a multi-stage process that combines material preparation with a unique chemical bonding technique. It's less like gluing a separate part onto a shoe and more like baking the components together.

Stage 1: Preparing the Rubber

First, the raw rubber compound is mixed to achieve the desired properties of grip and durability. This mixture is then run through rollers in a process called calendering, which forms it into large, consistent sheets of uncured rubber.

Stage 2: Shaping and Initial Assembly

The uncured rubber sheets are die-cut into the precise shape of the outsole. The shoe's upper, already formed and sewn, is prepared for bonding. A layer of adhesive is applied to the bottom of the upper before the shaped rubber outsole is carefully placed onto it.

Stage 3: The Vulcanization "Baking"

This is the defining step. The entire shoe assembly is placed into a specialized oven or press. It is subjected to intense heat and pressure, which triggers the vulcanization. This chemical process creates strong cross-links within the rubber polymers, curing the soft rubber into a tough, elastic, and durable sole. Crucially, it also permanently fuses the sole to the upper.

Stage 4: Finishing with Foxing

After cooling, a strip of rubber tape, known as foxing, is wrapped around the seam where the upper meets the outsole. The shoe is often heated a second time to bond this tape, which adds significant structural strength and durability to the connection. Finally, the edges are trimmed for a clean, finished appearance.

Understanding the Trade-offs

The vulcanization process directly creates the signature characteristics of the shoe, leading to a clear set of benefits and drawbacks.

The Benefit: Flexibility and Board Feel

Because the sole is thin and cooked directly onto the upper, the shoe is exceptionally flexible. This creates an excellent "board feel," allowing the wearer (often a skateboarder) to feel the texture of the surface beneath their feet with great precision.

The Drawback: Less Support and Durability

The same simple, thin construction offers minimal cushioning and foot support compared to more complex sole constructions like a cupsole. The single layer of rubber can also wear out faster under heavy use, especially in high-impact activities.

The Result: A Classic and Affordable Style

Vulcanized construction is a relatively straightforward and cost-effective manufacturing process. This often makes vulcanized shoes, like classic skate shoes and canvas sneakers, more affordable and gives them their iconic flat-soled, minimalist look.

Making the Right Choice for Your Goal

Understanding this construction method helps you select the right shoe for your specific needs.

- If your primary focus is maximum board feel for skateboarding: A vulcanized shoe is the ideal choice due to its unmatched flexibility and direct connection to the board.

- If your primary focus is all-day comfort and impact absorption: You may prefer a shoe with a cupsole, which offers superior cushioning and foot support.

- If your primary focus is classic style and affordability: Vulcanized shoes deliver a timeless aesthetic that is both versatile and budget-friendly.

Ultimately, knowing how a vulcanized sole is made empowers you to recognize why it feels and performs the way it does.

Summary Table:

| Stage | Key Action | Result |

|---|---|---|

| 1. Prep | Mixing & calendering raw rubber | Sheets of uncured rubber |

| 2. Assembly | Attaching cut sole to upper with adhesive | Initial assembly ready for curing |

| 3. Vulcanization | Baking in high-heat, high-pressure oven | Permanent bond between sole and upper |

| 4. Finishing | Applying and bonding foxing tape | Added structural strength and clean finish |

Need high-quality vulcanized footwear for your brand or store?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and flexible vulcanized shoes and boots for distributors, brand owners, and bulk clients. Our expert production capabilities ensure the classic look and superior board feel your customers want.

Contact us today to discuss your manufacturing needs and get a quote!

Visual Guide

Related Products

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Lightweight Cushioned Athletic Sneakers for Custom Bulk Production

People Also Ask

- How do non-slip athletic shoes differ from regular athletic shoes? Discover the Grip Technology

- How do athletic shoes with non-slip features differ from regular ones? Discover the Grip Advantage

- Does more ground contact area mean better support? Unlock the Secrets of Stable Footwear

- Does exercising with a friend or partner enhance safety? Unlock the 'Buddy System' Benefits

- Why is the use of flat-soled or professional training shoes essential for WBV? Maximize Vibration Energy Transfer