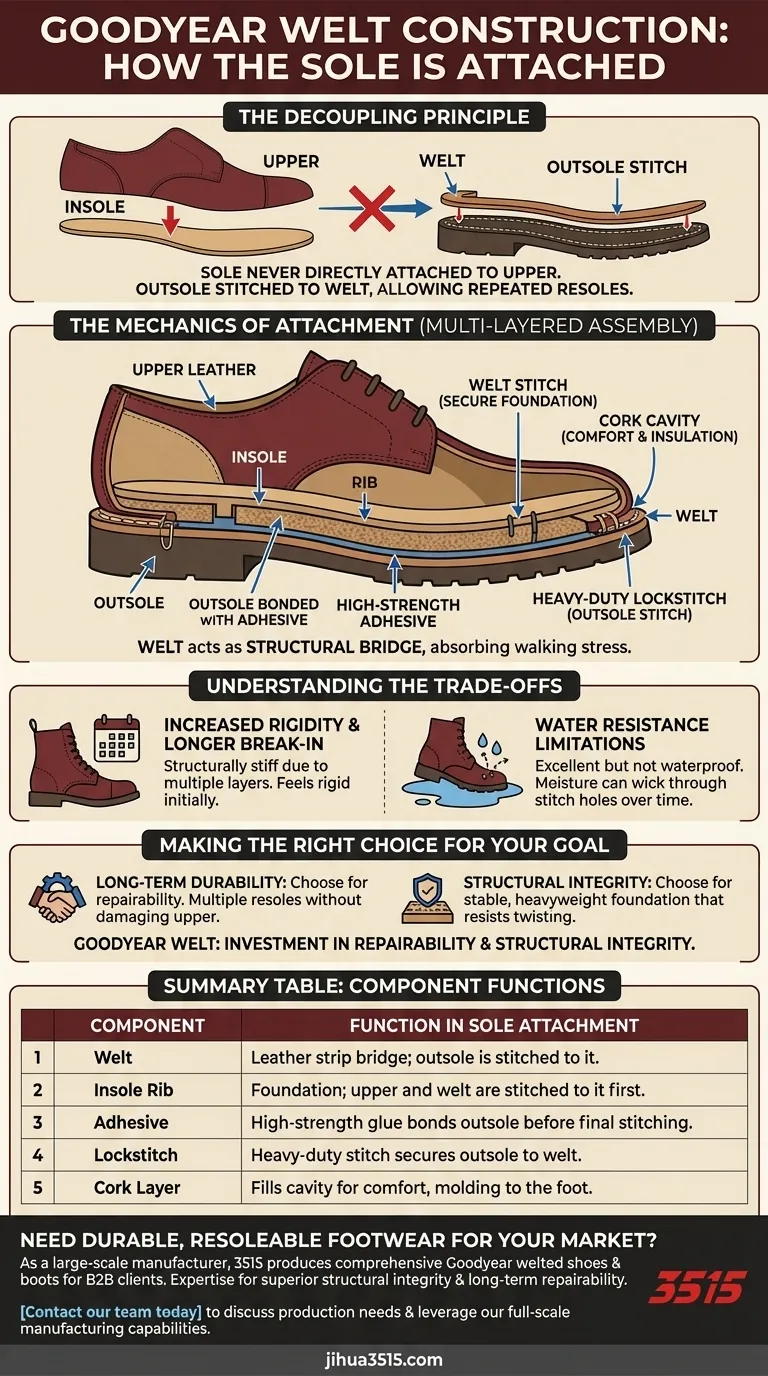

In Goodyear welt construction, the sole is never attached directly to the upper leather or the insole. Instead, the outsole is stitched to a "welt"—a strip of leather that runs around the perimeter of the shoe—typically using a combination of a high-strength adhesive and a heavy-duty lockstitch.

The defining characteristic of this method is decoupling. By stitching the outsole to the welt rather than the shoe’s main structure, the sole can be cut off and replaced repeatedly without compromising the integrity of the upper leather.

The Mechanics of Attachment

The robustness of a Goodyear welted shoe comes from its multi-layered assembly. Understanding how the sole is attached requires looking at the specific sequence of connections.

The Critical Role of the Welt

The welt acts as a structural bridge. It is a leather strap that encircles the shoe, effectively sandwiching the upper materials between itself and the sole.

Its primary function is to accept the final stitch. This ensures that the stress of walking is absorbed by this replaceable strip rather than the delicate upper leather.

The Two-Stitch System

The construction relies on two distinct stitching steps to hold the unit together.

First, the upper leather and the welt are stitched to a rib on the underside of the insole. This creates the secure foundation of the shoe.

Second, the outsole is stitched directly to the welt. This is the visible stitching you often see running around the edge of the shoe sole.

The Role of Adhesives

While stitching provides mechanical strength, it is rarely used alone.

Before the final stitching occurs, the outsole is usually bonded to the assembly using high-strength adhesive, such as contact cement or hide glue. This ensures a tight seal and prevents the sole from shifting during the stitching process.

The Cork Cavity

Between the insole and the outsole, a cavity is formed by the thickness of the welt.

This space is filled with a cork compound. While not a fastener, this layer is crucial for comfort, as it molds to the foot over time while providing insulation.

Understanding the Trade-offs

While Goodyear welt construction is often considered the "gold standard" for durability, it presents specific engineering implications you should be aware of.

Increased Rigidity

Because the sole attachment involves multiple layers—the insole rib, the welt, the adhesive, and the outsole—the boot is structurally stiff.

This results in a longer break-in period. The shoe will feel rigid initially compared to cemented or direct-inject constructions.

Water Resistance Limitations

The welt offers excellent water resistance compared to other methods, but it is not waterproof.

Because the attachment relies on stitching, moisture can eventually wick through the thread holes or the welt crevice during prolonged submersion.

Making the Right Choice for Your Goal

The method of sole attachment dictates the lifespan and maintenance schedule of your footwear.

- If your primary focus is Long-Term Durability: Choose Goodyear welt construction because the independent stitching of the sole allows for multiple resoles without damaging the upper.

- If your primary focus is Structural Integrity: Rely on this method because the insole rib and welt system provide a stable, heavyweight foundation that resists twisting.

The Goodyear welt is an investment in repairability, sacrificing initial flexibility for a shoe that can be rebuilt from the bottom up.

Summary Table:

| Component | Function in Sole Attachment |

|---|---|

| Welt | Leather strip acting as a bridge; the outsole is stitched to it. |

| Insole Rib | Foundation; the upper and welt are stitched to it first. |

| Adhesive | High-strength glue bonds the outsole before final stitching. |

| Lockstitch | Heavy-duty stitch secures the outsole to the welt. |

| Cork Layer | Fills cavity for comfort and insulation, molding to the foot. |

Need Durable, Resoleable Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures superior structural integrity and long-term repairability for your customers.

Contact our team today to discuss your production needs and leverage our full-scale manufacturing capabilities.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards