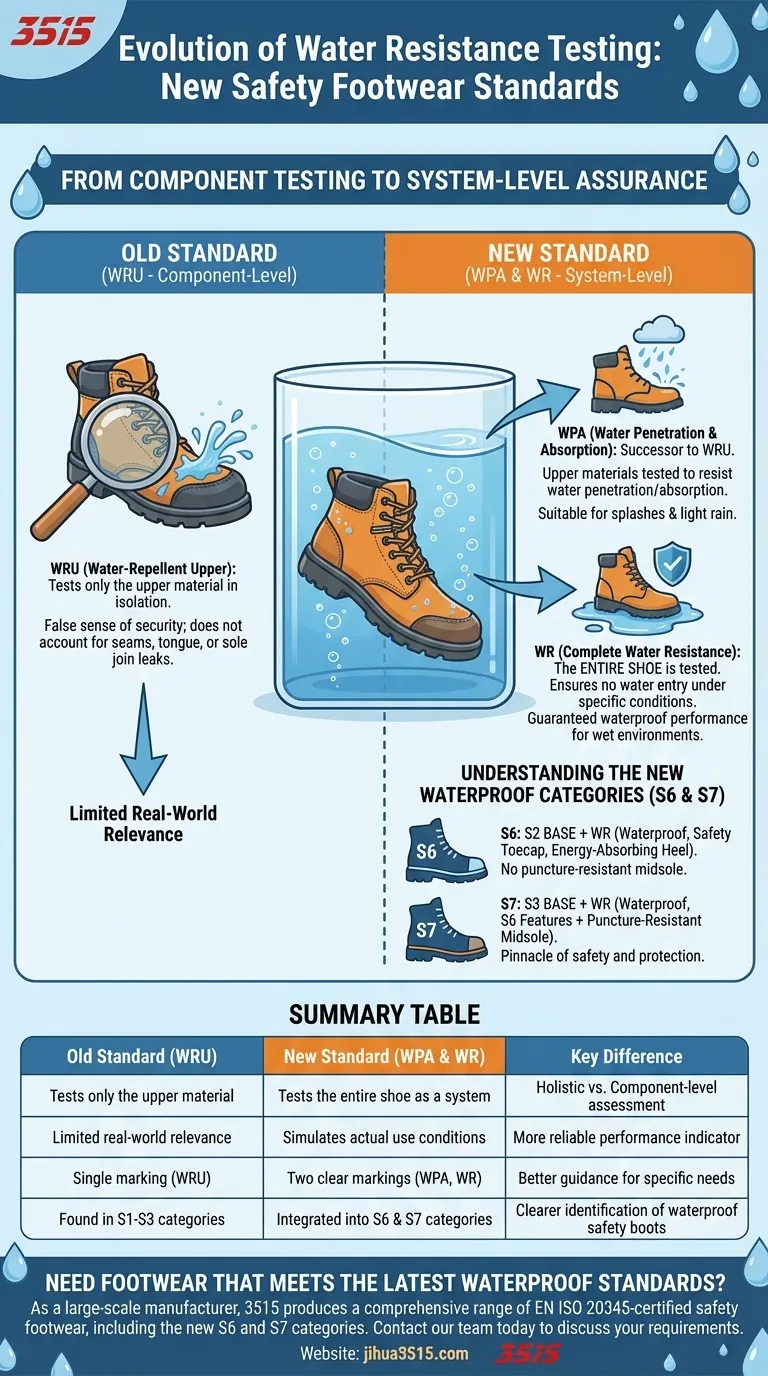

The fundamental change in water resistance testing is a shift from evaluating a single component to testing the entire shoe as a complete system. The old WRU (Water-Repellent Upper) test, which only assessed the upper material, has been replaced by more comprehensive ratings: WPA (Water Penetration and Absorption) for the upper and WR (Water Resistance) for the whole boot.

The new standard moves beyond simply testing if a material is water-repellent and instead focuses on whether the entire shoe can actually keep your foot dry in real-world conditions. This provides a far more reliable and practical measure of waterproof performance.

From Component Testing to System-Level Assurance

The previous standard had a critical limitation: it tested the upper material in isolation. This could create a false sense of security, as a shoe's true water resistance depends on its total construction.

The Old Standard: The WRU Limitation

The WRU (Water-Repellent Upper) marking indicated that only the leather or fabric of the upper resisted water.

This test did not account for the most common points of water entry, such as seams, the tongue gusset, or the join between the upper and the sole. A boot could have a WRU-rated upper but still leak easily.

The New Standard: A Holistic Approach

The new standard recognizes that a shoe is a system. It evaluates how the materials, seams, and sole construction work together to prevent water ingress.

This holistic testing method simulates real-world challenges more accurately, giving a much clearer picture of how the footwear will perform when submerged or exposed to heavy rain.

Decoding the New Water Resistance Markings

To reflect this new testing philosophy, the old WRU marking has been retired and replaced with two distinct classifications that provide much greater clarity.

WPA: Water Penetration and Absorption

The WPA marking is the direct successor to WRU. It specifically denotes that the shoe's upper materials have been tested to resist water penetration and absorption.

This rating is suitable for environments where exposure to water is limited to splashes or light, intermittent rain.

WR: Complete Water Resistance

The WR marking is the new, higher standard for waterproof footwear. It signifies that the entire shoe has passed a rigorous waterproof test.

To achieve a WR rating, the shoe is tested to ensure no water penetrates the inside after being subjected to specific conditions, confirming the integrity of the entire structure. This is the marking you should look for if you need guaranteed waterproof performance.

Understanding the New Waterproof Categories: S6 and S7

The new standard also introduces two new top-tier safety categories that integrate the WR marking as a core feature, making it simpler to identify fully waterproof footwear.

S6: Waterproof Safety

The S6 category builds upon the S2 base (which includes a safety toecap and energy-absorbing heel) by adding the WR (Water Resistance) property.

Footwear rated S6 is fully waterproof but does not include a puncture-resistant midsole.

S7: The Highest Level of Protection

The S7 category is the new pinnacle of safety footwear. It starts with an S3 base (toecap, energy-absorbing heel, and puncture-resistant midsole) and adds the WR marking.

An S7 boot provides complete waterproof protection combined with resistance to sole puncture, making it ideal for the most demanding and wet work environments.

Making the Right Choice for Your Environment

Your choice now directly maps to the level of water protection you actually need, removing the ambiguity of the old system.

- If your primary focus is protection from occasional splashes or light rain: Look for the WPA marking, which ensures the upper material itself resists water penetration.

- If your primary focus is working in wet environments with standing water: You must select a shoe with a WR marking, found in the new S6 or S7 categories, for guaranteed protection.

Ultimately, these changes empower you to select footwear based on a true measure of its complete waterproof performance.

Summary Table:

| Old Standard (WRU) | New Standard (WPA & WR) | Key Difference |

|---|---|---|

| Tests only the upper material | Tests the entire shoe as a system | Holistic vs. component-level assessment |

| Limited real-world relevance | Simulates actual use conditions | More reliable performance indicator |

| Single marking (WRU) | Two clear markings (WPA, WR) | Better guidance for specific needs |

| Found in S1-S3 categories | Integrated into S6 & S7 categories | Clearer identification of waterproof safety boots |

Need footwear that meets the latest waterproof standards?

As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345-certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof shoes and boots, including the new S6 and S7 categories, ensuring your workers have the right protection.

Let's discuss your requirements: Contact our team today to find the perfect waterproof safety solution for your market.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection