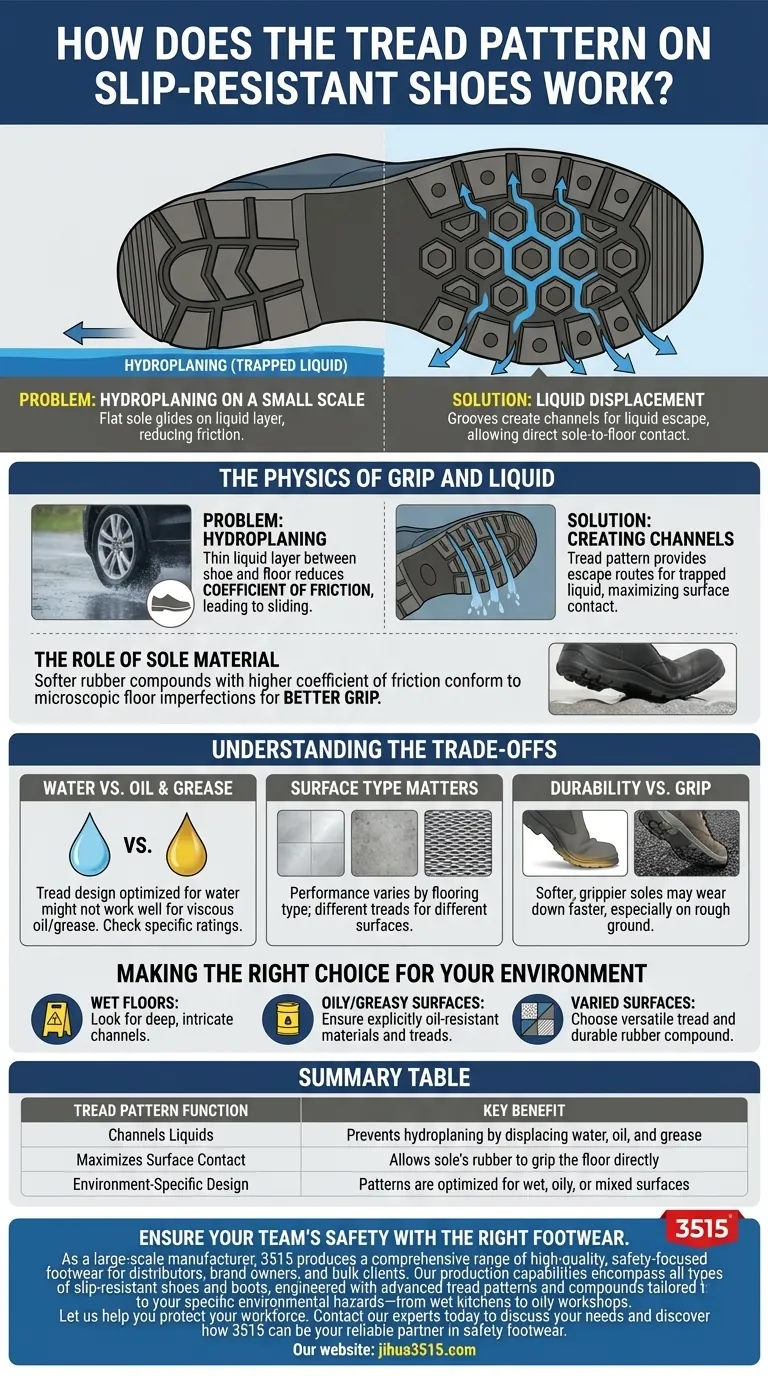

At its core, the tread pattern on a slip-resistant shoe works by channeling liquid away from the bottom of the sole. These patterns, often hexagonal or circular, create deep grooves that prevent water or other contaminants from being trapped underneath. This displacement allows the rubber sole to make direct contact with the floor, maximizing grip and preventing hydroplaning.

The primary function of a slip-resistant tread is not to "grab" the floor, but to clear a path for the shoe's sole to make solid contact. By effectively managing liquids, the design maximizes the natural friction between the sole and the walking surface.

The Physics of Grip and Liquid

To understand why tread patterns are so critical, we first need to look at the forces at play when you walk on a wet or greasy surface.

The Problem: Hydroplaning on a Small Scale

When you step on a wet floor with a flat-soled shoe, a thin layer of liquid gets trapped between your shoe and the floor. This layer of liquid dramatically reduces the coefficient of friction, which is the force that prevents two surfaces from sliding past each other. Your shoe ends up gliding on the liquid, not gripping the floor—a micro-version of a car hydroplaning on a wet road.

The Solution: Creating Channels for Displacement

The tread pattern introduces a network of deep grooves and channels into the sole. When pressure is applied as you step, this design gives the trapped liquid an escape route. The liquid is squeezed out from under the load-bearing parts of the sole and into the grooves. This allows the solid parts of the rubber sole to make firm contact with the actual floor surface.

The Role of Sole Material

While the tread pattern is essential for clearing liquid, the material of the sole itself is what creates the final grip. Slip-resistant shoes typically use a softer rubber compound. This softer material has a higher coefficient of friction and can conform better to the microscopic imperfections of a floor surface, further increasing its gripping power once the liquid has been displaced.

Understanding the Trade-offs

Choosing the right slip-resistant shoe involves more than just looking for a deep tread. The effectiveness of a shoe is highly dependent on the specific work environment.

Water vs. Oil and Grease

A tread pattern that excels at displacing water may not be as effective on more viscous liquids like oil or grease. Oil is harder to channel away and can also chemically interact with certain rubber compounds, reducing their effectiveness over time. Always check if a shoe is specifically rated for oily conditions if that is a hazard in your workplace.

Surface Type Matters

The type of flooring also plays a significant role. A shoe designed for the smooth, hard surface of a commercial kitchen tile might perform differently on unsealed concrete or a grated metal walkway. The tread pattern and sole material are optimized for specific types of surfaces.

Durability vs. Grip

There is often a trade-off between the softness of the rubber sole and its durability. A very soft, grippy sole may wear down more quickly, especially on rough surfaces like asphalt or concrete. The shoe's intended use often dictates this balance.

Making the Right Choice for Your Environment

Your selection should be guided by a clear understanding of your specific workplace hazards.

- If your primary focus is wet floors (e.g., dishwashing areas, food prep): Look for shoes with deep, intricate channels designed to displace large amounts of water quickly.

- If your primary focus is oily or greasy surfaces (e.g., automotive shops, industrial kitchens): Ensure the shoe is explicitly oil-resistant, as both the tread design and the rubber compound are specifically formulated for this challenge.

- If you work on varied surfaces: Consider a shoe with a versatile tread pattern and a durable rubber compound that balances grip with longevity.

Ultimately, the right slip-resistant shoe is a critical piece of safety equipment tailored to the specific risks of your environment.

Summary Table:

| Tread Pattern Function | Key Benefit |

|---|---|

| Channels Liquids | Prevents hydroplaning by displacing water, oil, and grease. |

| Maximizes Surface Contact | Allows the sole's rubber to grip the floor directly. |

| Environment-Specific Design | Patterns are optimized for wet, oily, or mixed surfaces. |

Ensure Your Team's Safety with the Right Footwear

Choosing the correct slip-resistant shoe is crucial for workplace safety. As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality, safety-focused footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with advanced tread patterns and compounds tailored to your specific environmental hazards—from wet kitchens to oily workshops.

Let us help you protect your workforce. Contact our experts today to discuss your needs and discover how 3515 can be your reliable partner in safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene